-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

Ansysブログ

November 3, 2023

MOMコンデンサ、MIMコンデンサ、およびMOSコンデンサの違い

最も基本的なレベルでは、すべてのコンデンサは誘電体(絶縁体)材料によって分離された導体(プレート)を介してエネルギーを貯蔵します。一方のプレートが正電荷を受け取り、もう一方のプレートが負電荷を受け取る場合、コンデンサが電荷を保持しています。コンデンサには、デジタル回路でのコンピュータメモリの保存、電子信号からのノイズのフィルタリング、回路の一部を別の部分の影響から保護するなど、さまざまな用途があります。

一般的な3種類のアナログ集積回路コンデンサ、すなわち金属-酸化物-金属(MOM: Metal-Oxide-Metal)コンデンサ、金属-絶縁体-金属(MIM: Metal-Insulator-Metal)コンデンサ、金属-酸化物-半導体(MOS: Metal-Oxide-Semiconductor)コンデンサをご紹介します。

金属-酸化物-金属(MOM)コンデンサとは

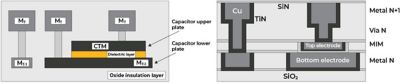

金属-酸化物-金属(MOM)コンデンサは、チップに使用される小型で汎用性の高いデバイスです。両手を組み合わせた指のように相互にかみ合う、導体層によって形成されたマルチフィンガーコンデンサです。標準的な金属配線(およびオプションとして、配線基板上のめっきスルーホールであるビア)を使用してコンデンサのプレートが形成され、プレート間の水平方向(層内)の容量結合効果によって必要な静電容量が生成されます。

この水平方向の容量結合は、垂直方向の結合よりも優れたマッチング特性をもたらします。それは、主に導体層や誘電体層の厚さではなく、水平方向寸法のプロセス制御が強化されているためです。静電容量密度を高めるために、ビアを使用して複数の導体層を並列に接続し、垂直な導体の壁またはメッシュを形成できます。通常、MOMコンデンサでは、静電容量密度を最大化するために、導体の線幅と間隔が最小である導体層(M1~M5など)が採用されます。

MOMコンデンサの構造

MOMコンデンサの利点

- コストが低い

- 静電容量密度が高い

- 優れた高周波(RF)特性

- 優れたマッチング特性

- 追加のマスク層が不要

- 対称平面構造

MOMコンデンサの短所

- 底面プレートの寄生成分が中程度

- 密度が低い

- 直列インダクタンスと抵抗が比較的高い

- 絶縁破壊電圧が低い

MOMコンデンサの適用分野

- 高速集積回路(IC)

- マイクロエレクトロニクス

- RF回路やアナログ回路

- 発振回路

金属-絶縁体-金属(MIM)コンデンサとは

金属-絶縁体-金属(MIM)コンデンサは、小型コンデンサのもう1つのクラスで、大きな利点をもたらします。導体プレート(電極)が絶縁材料(誘電体)によって分離されている平行板コンデンサのようなものです。これらのコンデンサは、単位面積あたりの静電容量が高いことから広く採用されています。静電容量値をさらに高めるために、MIMコンデンサは標準的な製造プロセスによる2つの導体層(多くの場合、最上層)と、その間に特殊な導体層を使用した合計3枚のプレートで構成されています。この独自の構成により、MIMコンデンサは、その絶縁誘電体材料の特徴である安定した性能と低い漏れの利点を活かしながら、より高い静電容量密度を達成できます。

MIMコンデンサの構造

MIMコンデンサの利点

- 安定した静電容量

- 単位面積あたりの静電容量が高い

- 適切な品質係数

- 適切な線形性

MIMコンデンサの短所

- マスク層の作成に特殊なプロセスが必要

- コストが増加

MIMコンデンサの適用分野

- 集積回路(IC)

- メモリモジュール

- RFおよびマイクロ波デバイス

- 光検出器

金属-酸化物-半導体(MOS)コンデンサとは

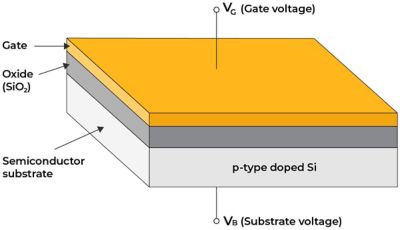

金属-酸化物-半導体(MOS)コンデンサは、本質的にはコンデンサとして使用されるトランジスタです。ゲートがコンデンサの上面プレートであり、ドレインとソースの接続が底面プレートを構成し、ゲートからの薄い酸化膜層が絶縁体層となります。MOSコンデンサは、単独で使用されるデバイスではありません。MOSトランジスタ(金属酸化膜半導体電界効果トランジスタ(MOSFET))の構成デバイスとして使用されています。

MOSコンデンサの静電容量値は、ゲートに印加されるDC電圧によって異なります。電圧が変化すると、ゲートの空乏領域が変化し、誘電特性が変化して、それによって静電容量が変化します。MOSコンデンサは、DC電圧が一定のままであるローカル電源デカップリング用途に特に有用です。

MOSコンデンサの利点

- MIMコンデンサよりも単位面積あたりの静電容量が高い

- ゲートの絶縁体(SiO2)が薄い

MOSコンデンサの短所

- 使用電圧が制限されるため、静電容量が大きく変化する

- 底面プレートからの寄生抵抗が性能に影響を及ぼす

MOSコンデンサの適用分野

- IC

- アナログ回路

- 電圧基準回路

- 同調フィルタ

p型半導体MOSコンデンサ

MOM、MIM、およびMOSの比較

プロパティ | MOM | MIM | MOS |

構造 | 酸化物誘電体層を持ち、同層で相互にかみ合わせた構造 | 絶縁材料(窒化ケイ素、五酸化タンタルなど)で分離された2つ以上の導体プレート | 金属ゲート電極、酸化膜絶縁層、および半導体基板 |

誘電体材料 | 金属酸化膜(SiO2、Al2O3など) | 絶縁体(Si3N4またはTa2O5など) | 絶縁体(SiO2) |

静電容量密度 | 高 | 中~高 | 中~高 |

電圧による静電容量の変化 | 低 | 低 | 高 |

温度による影響 | 若干影響を受けやすい | 中程度に影響を受けやすい | 若干影響を受けやすい |

製造プロセス | 比較的シンプルなプロセス | 比較的複雑なプロセス | 標準的なプロセス |

寄生 | 高 | 低 | 高(主に底面プレート) |

適用分野 | 集積回路、マイクロエレクトロニクス、アナログ回路やRF回路 | 集積回路、メモリモジュール、アナログ回路やRF回路 | 集積回路、MOSFET、センサー、アナログ回路やデバイス |

シミュレーションを使用した静電容量の抽出

MOMコンデンサは、極めて細い多数のフィンガーで構成される大規模で複雑な構造です。これらはレイアウト依存効果(LDE: Layout-Dependent Effect)によって生じる歪みの影響を強く受けます。そのため、LDEを正確にモデル化して、MOMコンデンサの正確なモデルの計算を保証する必要があります。設計者は、レイアウト全体を考慮しながらMOMコンデンサをモデル化することで、繊細なデバイスを設計する上で不可欠となる、回路の他の部分との容量結合を予測できるようになります。しかし、従来の電磁界(EM)ソルバーを導入しても、このレベルの精度を達成できるとは限りません。そのため、多くの設計者はMOMコンデンサを個別コンポーネントとして扱い、モデルをテストベンチに直接接続する方法を採用しています。

MIMコンデンサの製造では、製造プロセス中に追加のマスク層を必要とするため、より大きな課題となります。MIMコンデンサを定義して設計するために、特定のMIM層が技術ファイルに追加されます。静電容量の精度を予測するには、レイアウト全体を考慮した完全なMIM構造をモデル化しなければなりません。

MOMおよびMIMコンデンサは、IC、特にRF回路やアナログ回路で広く採用されています。レイアウト全体を考慮しながら静電容量の精度とマッチングに関する要件を満たすためには、シミュレーションソフトウェアを使用して、こうしたコンデンサを正確にモデル化することが重要です。Ansys RaptorHは、すべての受動コンポーネントの電磁界モデルを抽出する機能や、完成したあるいはまだ設計中のレイアウトを任意に配線する機能も備えています。こうしたコンポーネントには、平面(固体または多孔質)、伝送線路、スパイラルインダクタ、MIM/MoMコンデンサなどがありますが、これらを高速/高周波配線とともに抽出して、完全に連成された電磁界モデルを計算できます。また、電磁界抽出実行を非常にシンプルかつ迅速に設定するための自動化機能も含まれています。

IC設計を適切に設計するには、高度なシミュレーションソフトウェアを使用して、これらのコンデンサを高精度でモデル化することが重要です。Ansys RaptorHの詳細はこちら