-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

ANSYS BLOG

April 16, 2019

How to Simulate and Design the Microstructures of Composites and Other Complex Materials

It isn’t easy for engineers to capture and model the microstructures of materials — like composites. If engineers had to faithfully account for all the details of the microstructure, the computational load to run a finite element simulation would be well beyond current computing capabilities.

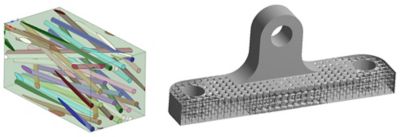

Material microstructures can be too complex to be captured at a refined level of

detail. Like when a misaligned fiber microstructure (left) is used in a complex

bracket designed using topology optimization (right).

Given the trend toward more complex geometry — like topology-optimized geometry and assemblies — the computational load of simulations will grow. If these complex geometries also have complex microstructures, the only way to simulate them is by homogenizing the material properties.

Ansys Material Designer, available in Ansys Mechanical Enterprise, enables engineers to optimize microstructures and homogenize the material properties of complex materials and composites.

For an in-depth demo of Material Designer, watch the video below:

A demo of Material Designer’s abilities to homogenize the material

properties of complex materials and composites.

How Material Designer Defines a Composite Material’s Microstructure

Material Designer is able to compute the elastic and thermal properties of heterogeneous material architectures — like the architectures found in composites.

It does this by first defining the properties of the base materials and the representative volume element (RVE) of the microstructure.

An RVE is defined as the smallest volume element of a material with an accurate statistical representation of the typical material properties used in a macroscale model.

Engineers can use Material Designer to customize the dimensions and influence the size and material properties of an RVE. They can even make custom RVEs.

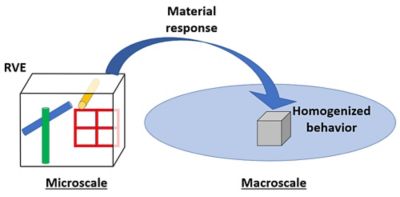

Material Designer captures the material response of a heterogeneous material architecture and expands it into a homogenized macroscale behavior.

Several RVE geometries are predefined in Material Designer,

but engineers can also make user-defined RVEs.

With Material Designer, engineers can analyze RVEs based on custom and predefined geometry types. Some of the predefined microstructures available in Material Designer include:

- Unidirectional fiber.

- Woven fiber.

- Chopped, random fiber.

- Long, random fibers.

- Chopped, ordered fibers.

- Long, ordered fibers.

Engineers can also define a material’s microstructure using a lattice. These lattices can be user-defined or based on predefined shapes like diamonds, cubic, octet or pyramids.

Simulate Complex and Composite Microstructures Using Material Designer

Once Material Designer has defined the homogenized properties of a material microstructure, the data can be used in Ansys Mechanical or Ansys Workbench.

The material properties computed through Material Designer can be reused in subsequent simulations. This means that once engineers finish designing a new material or composite, they can reuse their work for other part designs.

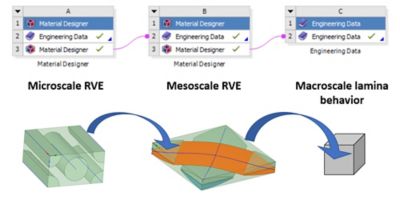

Additionally, different Material Designer analysis cells can be tied together within a simulation. This helps engineers capture how material properties can vary based on scale and location.

Material Designer analysis cells can be tied together to obtain the material behavior at different scales and locations.

Finally, Material Designer can be completely parameterized. This enables engineers to optimize the RVE architecture and the material properties by passing the parameters into an optimization workflow.

To learn more, read the white paper: Simulating Composite Structures.