-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TOPIC DETAILS

What is Simulation?

A simulation is an imitative representation of the function of a process or system that could exist in the real world. The term comes from the Latin root simulare, meaning “to imitate.” Simulations are conducted for many purposes, including predicting a system's behavior, educating students, troubleshooting unwanted behavior, verifying an expected response, validating an approach, optimizing aspects of the process, or predicting future responses.

Simulation is used when you cannot access the real system, if the real-life situation is too dangerous, or if the product or process is still in the design stage.

How are Simulations Conducted?

Engineers conduct simulations using physical prototypes, mathematical models, or computer methods. Users first input a set of variables into the model and then capture a set of output values. They do this through the following steps:

- Problem definition: The goals of the simulation are established, with clear inputs and outputs documented.

- Preprocessing: The simulation user builds physical, mathematical, or computer models for their simulation. This is the step in which factors like constraints, boundary conditions, materials, and geometry are specified.

- Solve: The model or models are solved, usually using computer programs, producing the desired outputs.

- Post-processing: The user deploys a combination of human review and computer data analytics to look at the outputs relative to the inputs and gather information for decision-making. The output from post-processing can be text, images, graphs, or animations.

- Iterations: One simulation is usually not enough. Users vary input parameters by hand or using optimization tools and then repeat the simulation to gain more information about the system.

Common Simulation Applications

Researchers, analysts, decision-makers, and engineers conduct simulations across many disciplines to gain insight. A few examples of simulations across areas of interest include:

- Weather: Simulation is used heavily in weather forecasting. A wide range of simulation software uses empirical data and mathematical models to predict the probability of future temperatures, wind, pressure, precipitation, and natural disasters worldwide.

- Product pricing: Instead of changing prices and seeing how they impact sales, decision-makers can use simulation, often based on AI methods, to understand the potential impact of price changes.

- Supply chains: Many tools use timing and dependency to model the behavior of a company's supply chain. Users can quickly simulate workarounds for disruptions or optimize their supply chain for cost, speed, or robustness.

- Machines: The largest use of simulations is in the design and life cycle management of machines. From computer chips to rocket engines, engineers use simulations that model the laws of physics to drive product design to meet design specifications, optimize performance, and minimize costs.

- Electronic design: Electronic circuits have complex interactions based on electric and magnetic fields that are difficult to predict. Circuit simulators are used to calculate the behavior of electrical circuits in the design stage. These simulators predict voltages, currents, and electromagnetic field strength at every point in time.

- Chemical processing: Engineers use a variety of process simulation tools to represent the component and system behavior of chemical plants and refineries.

- Molecular processes in biology: Recent advances in molecular process modeling and greater understanding of how complex organic molecules interact with each other are disrupting the healthcare industry. Researchers can develop new formulations for vaccines, antibiotics, and therapies through simulation before spending millions on drug syntheses and clinical testing.

- Video games: Almost everyone has interacted with simulations in the form of video games. Computer-based games can be as simple as a game of solitaire on a mobile phone, or they could include complex algorithms and virtual reality (VR) to simulate virtual worlds.

Why Simulation is a Valuable Tool

Simulation has become an integral part of decision-making across industries. As computer programs used to conduct modeling and simulation improve, the timeliness and value of simulation also increase. In most cases, stakeholders around a product or a process use simulation to understand something about that product or process. This information can reduce development costs, avoid expensive physical testing, minimize the need to make changes when the system or process is in use, and reduce the overall time to market for any new product or service.

The benefits of simulation, including reducing cost, improving safety, optimizing performance, and shrinking development times, can be categorized into one or more of the following:

1. Map the External Performance Across the Design Space

Measuring the performance of a real-world product only reveals how it performs under actual conditions — and only once the product exists. With computer models, researchers and engineers can explore as many situations the system could encounter as needed.

This process is called exploring the design space, and it gives engineers insight into how things behave in a situation they cannot measure or has not yet occurred. That information can be used to fix a problem, make a decision when several options are available, or provide details that differentiate a product or service.

2. Understand the Internal Performance

Some behaviors in a system simply can't be measured directly, either because no suitable measurement method exists or because adding a sensor or other measurement tool would change the system’s behavior. A computer simulation allows engineers to look inside the product or process they’re designing and obtain information. Knowing these otherwise-hidden values can help solve problems and drive better decisions.

3. Optimize Performance

The final significant advantage of simulation is the ability to change inputs and capture outputs to optimize the system or process you’re simulating. You can explore the data from multiple simulations or set up an optimization loop to achieve your goals. Regardless of the optimization methodology used, the process can greatly reduce cost, increase performance, and increase robustness.

Simulation Accuracy is Improving

The accuracy and value of simulations have grown significantly since the 1980s, in step with increased capabilities in high-performance computing (HPC), improved mathematical models, advances in computer science, better model-building software, and, most recently, advances in artificial intelligence (AI). Better software has also made simulation more accessible, and improved visualization and optimization tools now yield greater insight for users. Simulation has always had a positive impact when applied correctly. Improvements in accuracy have increased the benefits of simulation and expanded the range of situations in which it can be used effectively.

The Different Forms of Simulation in Engineering and Manufacturing

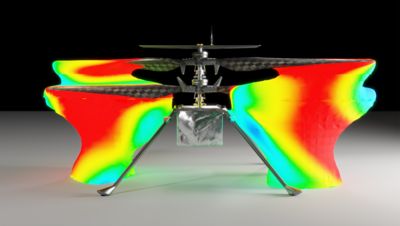

NASA’s Ingenuity helicopter relied heavily on simulation before it flew on Mars.

When most people in the engineering world hear the term “simulation,” they think of numerical simulation like finite element analysis (FEA) or computational fluid dynamics (CFD). These two forms of computer-aided engineering (CAE) are commonly used, but simulation comes in many forms. Here are the most common categories:

Physical Models

Before computers, building a physical prototype for testing used to be the most common type of simulation. These analog models served as a way to experiment with and understand the system. The manikins used in vehicle crash testing are a great example of a physical prototype. They mimic the behavior of a human body during impact in a simulated environment, as this is something that can’t be safely tested with an actual human. Physical testing is often used to validate computer simulations. The Ansys Hans Human Body Model is an example of a digital version of physical simulation.

The Ansys Hans Human Body Model replaces simple physical mannequins to deliver detailed data on how human bodies respond to impact events.

Closed-form Solutions

In some cases, engineers can capture the behavior of a system or a process — especially a manufacturing process — with a single equation that can be solved in real time. These closed-form solutions can stand alone or be combined with reduced-order models (ROMs) and data analytics in system models.

Data Analytics

Another type of simulation makes predictions from data collected from physical testing or the results of computer-generated models using discretization or closed-form solutions. This can be as simple as fitting an equation to the data or as complex as the latest AI and machine learning (ML) algorithms.

Discretization

Most real-world processes and systems are too complex to model using a simple equation or dataset. To simulate these situations, the object or process is divided into smaller parts, with each part described by simpler equations. Those equations are then assembled into a matrix and solved using numerical methods. This approach is used in tools like Ansys Mechanical structural FEA software, CFD programs like Ansys Fluent fluid simulation software, or 1D finite-difference simulation tools like Ansys Thermal Desktop software.

System Models

System models are built by connecting closed-form solutions or reduced-order models into a system of equations, in which the output from one node becomes the input in the next. System simulations can range in scale, from modeling the array of transistors in a microchip with tools like Ansys RedHawk-SC software to simulating satellites in orbit with Ansys Systems Tool Kit (STK) software. Model-based systems engineering (MBSE) is a growing methodology for systems design that replaces older, documentation-driven approaches.

Where the User Interacts is Important in Simulation

Another way to categorize different kinds of simulation is to look at where the user sits in the process. Human-in-the-loop (HiL) simulation places users directly in the simulation through a graphical user interface (GUI) — such as in Ansys SCADE software — or in a virtual reality environment. By placing a human in the simulation environment, teams can get hands-on experience with the system. A flight simulator is a common example, in which a user interacts with the simulation in real time.

In most simulations, humans are not involved in the solve portion. Instead, they use a variety of tools to capture and evaluate the results, then either make informed decisions with that information or pass it on to stakeholders who rely on it for their own decision-making.

Single Physics, Multiple Physics, and Multiphysics

Another distinction between different types of simulation is what physics domains they include and how they interact. A single-physics simulation solves for one type of unknown, like temperature, stress, pressure, or number of fatigue cycles. In such cases, you only need the equations and inputs that are relevant to that physics domain. In a simulation with multiple physics, the output from one simulation becomes the input for another. For example, you might calculate the heat generated by a microchip due to power losses, then input that value into a simulation evaluating thermal management options for the microchip.

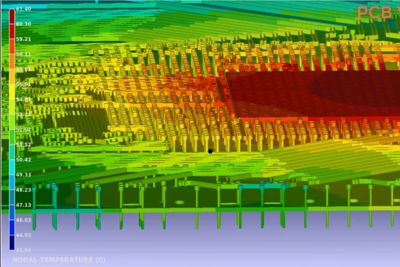

A multiphysics simulation closes the loop: The results from downstream simulations are fed into an upstream simulation. Going back to the microchip example, the chip’s temperature impacts its electromagnetic performance and resistivity, which in turn impacts the heat generated and the electrical performance of the chip. Multiphysics simulations with a tool like Ansys RedHawk-SC Electrothermal software automate the bidirectional interaction between electromagnetic and thermal physics. Multiphysics simulation is also common in turbine engine design and many manufacturing processes, such as casting, injection molding, and metal forming.

Types of Numerical Simulation Methods

All the approaches above that use mathematical approaches to simulate the real world can also be categorized by the numerical approach used by software programmers. The most common are:

- 1-D, Circuit, or Network Modeling: an approach in which the geometry of the model’s components is not explicitly represented. The program solves for inputs and outputs at nodes rather than over volumes or areas.

- Agent-Based Simulation: a technique that represents the system as a collection of autonomous agents that interact with each other.

- Computational Fluid Dynamics: a method used to represent the geometric behavior of fluid flow. It uses the finite element method (FEM), finite volume method (FVM), or finite difference method (FDM) to solve the partial differential equations (PDEs) created by discretization.

- Digital Twins: a general term that represents any digital representation of a physical object or system.

- Discrete Event Simulation (DES): an approach used to represent real-world systems, facilities, or processes as a sequence of events in time. The system state only changes at specific event points, so the solver moves from event to event rather than over a set time increment.

- Explicit Dynamics (EXD): a method within FEA with an explicit time integration approach to calculate responses to applied loads over small time increments. It is used mostly for highly dynamic and highly nonlinear behavior, such as impact simulations.

- Finite Difference Method: a technique that approximates derivatives by calculating the values of the PDEs in a discretized system.

- Finite Element Method: A method used in FEA that discretizes geometry into unique elements and solves PDEs for each element.

- Finite Volume Method: a method in which geometry is discretized into control volumes.

- Monte Carlo Simulation: a statistical approach to simulation in which cases are solved through repeated random sampling.

- Multibody Dynamics (MBD): an approach that represents the dynamic behavior of a system consisting of rigid or flexible bodies. It solves the full equation of motion for each component.

5 Examples of Modern Simulation in Engineering and Manufacturing

Ansys RedHawk-SC Electrothermal software can model both power distribution and temperature as a multiphysics model.

1. Microchip Signoff

Developing a new microchip, from memory devices to the latest system-on-a-chip (SoC) solutions, is extremely expensive. As a result, semiconductor foundries that manufacture these chips require developers to verify that a design is manufacturable through a series of standard simulations before the manufacturing process begins. These verification steps are referred to as signoff. A good example is Intel’s certification of Ansys power integrity and on-chip electromagnetic simulation tools for verification of their 18A process technology.

2. Robotics for Vehicle Painting

Painting automobiles is a critical step in every modern assembly line, and auto manufacturers rely heavily on robotics for this task. Engineers use CFD simulation tools like Fluent software to model the sprayers, a program like Ansys Motion software to model the robots and ensure efficient operation and avoid collisions, Ansys Maxwell software to optimize the robots’ electric motor drives, and the Ansys Scade One solution to simulate the control software and user interface.

3. Quantum Computer Design

Simulation has always been used to drive the design of computers, and that is especially true of quantum computers. The extremely low temperatures and nonintuitive quantum physics make simulation crucial in developing these new devices. Specialty tools like Ansys Lumerical INTERCONNECT software and Ansys RaptorQu software allow engineers to optimize their designs long before expensive manufacturing and testing begin.

4. Sustainable Fuels for Jet Engines

Aircraft turbine engines burn a huge amount of fuel, which significantly contributes to carbon emissions in the atmosphere. So, engine manufacturers are turning to simulation to help them develop alternative fuels that are sustainable to produce or release less carbon. They use chemical reaction simulators like Ansys Chemkin-Pro software to optimize combustion of new fuels and Mechanical or Fluent software to modify engines to support hydrogen-based fuels.

5. Formula E Racing

One of the best places to drive technological innovation is on the racetrack. A modern example is the growing motorsport of Formula E racing, where drivers and engineers test the latest in electric vehicle technology. To keep that competitive edge, the TAG Heuer Porsche Formula E team leans heavily on simulation for the validation of suggested design changes.

Contact us today to learn more about how Ansys software has enabled companies to push boundaries in their designs with the predictive power of simulation.

Related Resources

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.