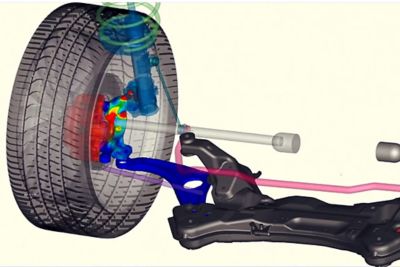

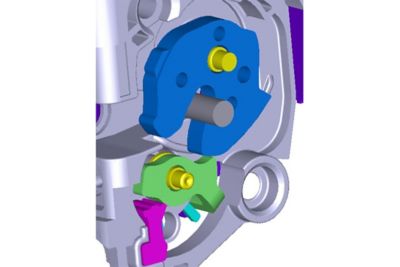

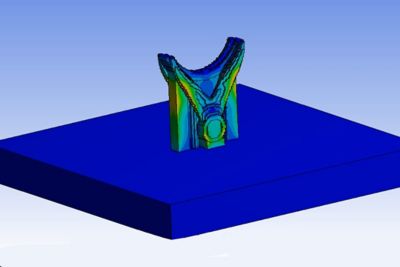

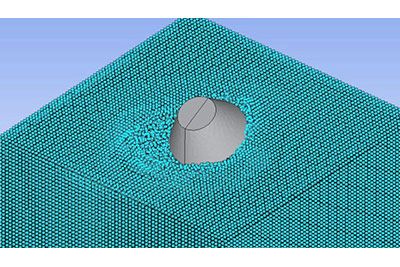

Ansys Motion is a next-generation engineering solution based on flexible multibody dynamics. It enables fast and accurate analysis of rigid and flexible bodies within a single solver system. Motion can reduce time-to-market by performing system motion performance, stress safety analysis, vibration analysis and fatigue analysis during the design process across many industrial applications. Motion’s integrated GUI provides a robust modeling environment for component and systems that can be analyzed independently or simultaneously, opening new doors during design and analysis.

Explore more Ansys Motion capabilities below.