-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

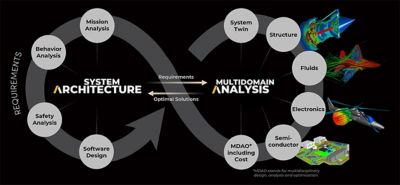

Model-based systems engineering (MBSE) is a methodology that focuses on using digital system and engineering domain models as the primary means of exchanging information, feedback, and requirements, as opposed to document-centric systems engineering. It involves the entire process of capturing, communicating, and making sure that the digital models we use to represent a system are coordinated and maintained throughout the system’s life cycle.

Prior to the 1990s, a system engineering design likely consisted of many related papers and documents containing drawings, diagrams, mathematical formulas, requirements, and other specifications for how the system would work. But around that time, projects became too large to rely on disconnected documents. Problems included:

- Upkeep of the design specification as the system’s concept evolved: If an engineer changed a single dimension on one document, they had to go through the entire stack of documents and make sure that change was made in every other document where it was located. If other copies existed, you could not be sure that the change was recorded in all copies.

- Human interpretation: It is entirely possible that two engineers could read the same sentence in the specification and come away with different understandings, given the ambiguities of human writing systems and language.

- Verifiability: There was no way to make sure that a calculation made on one page of the model was error-free before using it as input for another calculation further along in the process.

MBSE was developed to replace static documents with “intelligent” digital models that contain everything important about the system — the requirements, the architecture, and the interfaces between the pieces of the system. Instead of paper documents that were at best organized into folders, today these digital models are connected by a “digital thread” that can be followed to understand the entire design.

The overarching systems architect model (SAM) serves as an authoritative source of truth for everyone working on the project. This digital model has a central location that can be accessed by everyone working on the project but cannot be modified independently of others, preserving the single source of truth. Any changes made are automatically propagated throughout the model and checked for internal consistency and accuracy by the software.

Model-based systems engineering (MBSE) is an enabler for digital engineering.

The Core Components of MBSE

MBSE relies on three major components:

- The SAM, in which the system being designed is represented by a series of connected block diagrams that describe the system’s physical and functional architecture. It also contains a comprehensive list of the required qualities or functions that it needs to perform. SAMs are created using specialized software programs and utilize purpose-built languages to describe system architectures.

- Engineering simulation software. A SAM can be compared to a computer-aided design (CAD) drawing — it describes the system in detail, but there is no way to tell from the SAM alone if the system meets requirements. Because of this, the SAM must be coupled with engineering simulation. For example, if the airplane you are designing is required to withstand 6 Gs, then engineers need to simulate the airplane design to tell them if it is up for the task. Because a complex system might require engineers to execute many different types of simulation solvers — structural, fluids, electromagnetic, embedded software, safety, cybersecurity, etc. — it is important to be able to use many different types of simulation tools.

- A centralized computation center. Whether located somewhere on-premises or in the cloud, this centralized computation center contains the SAM and executable software. It performs all functions and stores all results of the MBSE process.

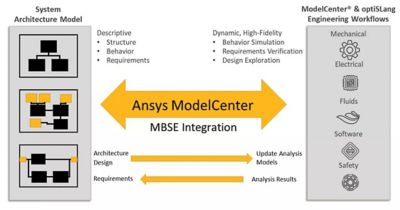

Achieving an MBSE Environment With Ansys Software Tools

In MBSE, the combination of the SAM, CAD, and computer-aided engineering (CAE) simulation tools creates the digital thread that links all the models and engineering data together. This occurs early in the design cycle and continues to function through the entire operational life cycle of the product. When changes are made, the digital thread ensures that updates to one model are automatically transferred to all the models in the system.

Ansys offers a SysMLv2 cloud-based SAM that is built from the ground up to support real-time collaboration and features close integration with other Ansys MBSE tools. It also includes a full-featured application programming interface (API) that enables it to be integrated with third-party tools such as requirements management and PLM tools. Ansys MBSE tools can provide that connection between the engineering simulation software and the SAM, enabling engineers to virtually verify their designs. So, if you are working on a project that has digital models containing structural, fluids, electromagnetic, safety, and embedded software simulations, Ansys ModelCenter model-based systems engineering software will coordinate the operation and data collection from:

- Ansys Mechanical structural finite element analysis (FEA) software

- Ansys Fluent fluid simulation software

- Ansys HFSS high-frequency simulation software

- Ansys medini analyze system-oriented safety analysis software

- Ansys SCADE embedded software product collection

ModelCenter software connects these simulation tools to the SAM for simulation-enabled MBSE. Consistent with Ansys’ commitment to providing an open ecosystem, ModelCenter software is a vendor-neutral solution that can automate the execution of any simulation tool within a workflow, even those from other software vendors.

As the design cycle progresses and the product design is refined, engineers can use Ansys MBSE technology to assess whether the as-designed system meets the specified requirements or whether changes must be made. When the requirements or the SAM are changed, the entire procedure can repeat until the results satisfy the specifications, verifying that the design will work as intended throughout the product’s lifetime. Only after these requirements have been satisfied will the team build a physical prototype of the design to perform physical tests.

The value of MBSE is that it enables better decisions to be made both early in development and throughout the design life cycle. The earlier a stakeholder can identify a problem, the easier and cheaper it is to correct.

MBSE provides value from requirements through retirement by enabling a disciplined system engineering approach. The digital models can be inspected, verified, and validated against a single source of truth, ensuring their internal consistency, which improves delivery, product yield, and both the top and bottom lines.

MBSE Examples: High-performance Aircraft Design

As an example, imagine that the Air Force has put out a bid to design a new plane that can fly 3,000 miles on a single load of fuel. You can design, build, and test the airplane the old way, or you can use a model-based approach.

If you decide to use an MBSE approach to design this complex new plane, you would first create a SAM that documents all the important requirements for the airplane, including that it must be capable of flying 3,000 miles without refueling. You would then use the SAM to describe the design you intend to build, including the system architecture, the desired behavior, interfaces between system components, and other specifications. At this point, you would use simulation to verify that the design you described meets all physical and behavioral requirements. Simulation would include fluid simulations for assessing aerodynamics, structural simulations for confirming mechanical strength, electromagnetic simulations for verifying the functions of the communications devices, etc.

For more complex, mission-based applications, engineers can use digital mission engineering software to simulate the complex “system of systems” structure of modern aerospace and defense (A&D) missions. Digital mission engineering combines digital modeling, simulation, testing, and analysis for aerospace, defense, telecommunications, and intelligence applications to evaluate mission outcomes at every phase of a system’s life cycle. These missions might involve hundreds of ground-, air-, water-, or space-based weapon systems that all have to communicate and coordinate their actions. Digital mission engineering simulation enables engineers and military personnel to execute a complicated mission virtually using physics-based simulations, which gives them confidence in the mission.

In a real-world example, Lockheed Martin Space used MBSE with ModelCenter software to simulate the mission trajectory for the OSIRIS-Rex spacecraft, whose mission was to grab a sample of an asteroid in a “touch-and-go” operation.

“Automating and integrating the simulation into this system model allows the team to rapidly identify potential issues with changes to mission requirements, as well as perform continuous verification of requirements and mission design parameters throughout the lifecycle of the spacecraft ...” says Phathom Athena Donald, a systems engineer for Lockheed Martin Space. “The overall improvement versus the original process was about a 7X speedup in turnaround time.”

U.S. Department of Defense Drives MBSE Adoption

By far the biggest boost to MBSE came from the U.S. Department of Defense (DoD), which issued DoDI 5000.97 in 2023. This aimed to standardize the implementation of digital engineering, formalizing MBSE as a requirement for all proposals related to US defence and weapons systems. It is being actively used in programs like Next Generation Air Dominance (NGAD), Future Vertical Lift (FVL) and the Navy’s digital shipbuilding initiatives. This directive has made the A&D sector the leading proponent of MBSE, in large part as a way to avoid project delays and cost overruns.

While A&D is leading the charge, other sectors are quickly catching up. The automotive industry, in pursuit of solutions for complex autonomous driving challenges, is also rapidly adopting MBSE. As complexity increases in other sectors, such as semiconductors, medical devices, alternative energy, the smart grid, and 5G communications, MBSE adoption will likely accelerate there, too.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.