Ansys Advantage Magazine

Discover Excellence in Engineering Simulation

Each issue of Ansys Advantage showcases customers’ stories and important trends across a variety of industries. Learn how engineering simulation is accelerating product development, adding value and reducing costs.

Digital Engineering: Conquer Complexity

"The focus now is on connecting all these disparate digital models to take advantage of the synergy from those connections, but also on the shift from merely focusing and optimizing on the individual part or discipline to the performance of the cyberphysical product as a whole."

— Andy Ko, Director, Ansys Professional Services

In This Issue:

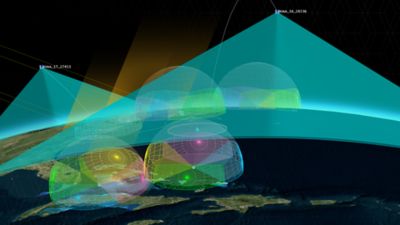

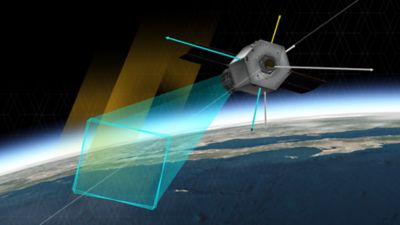

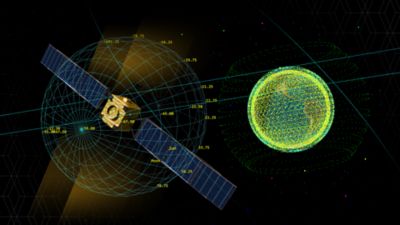

Ansys Advantage: Simulating Space Issue

Plan the Mission

Design the Assets

Protect the Assets

Take the Moonshot