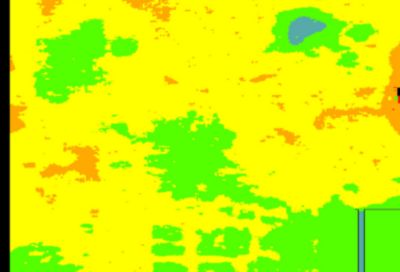

Ansys RedHawk-SC’s trusted multiphysics signoff analysis is a powerful way to reduce project and technology risk. RedHawk’s algorithms are certified accurate by all major foundries for all finFET processes and are proven in thousands of tapeouts.

The speed and capacity of RedHawk’s cloud-native SeaScape™ architecture enable ultra-large, full-chip power analyses by enlisting thousands of CPU cores with modest memory requirements. And RedHawk-SC’s advanced power analytics capabilities will calculate the timing impact of IR-drop, with coverage optimized to maximize possible activity scenarios.

These broad, silicon-correlated simulation results give designers the confidence they need to achieve higher performance and lower power by avoiding wasteful and expensive overdesign.

Thermal analysis and multi-die system analysis is enabled with the RedHawk-SC Electrothermal option, which adds full-system thermal and power integrity co-simulation for chips and 2.5D/3D IC packages, including package signal integrity and thermal-mechanical stress and warpage.