Quick Specs

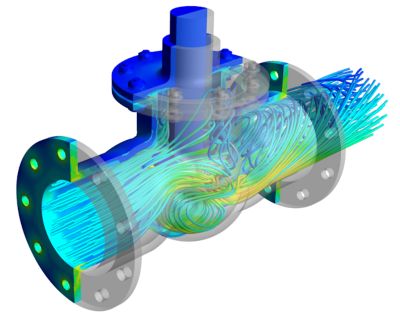

Accelerate your design cycle with this powerful fluid simulation software. Ansys Fluent contains the best-in class physics models and can accurately and efficiently solve large , complex models.

Ansys Fluent is the industry-leading fluid simulation software known for its advanced physics modeling capabilities and industry leading accuracy.

Ansys Fluent gives you more time to innovate and optimize product performance. Trust your simulation results with a software that has been extensively validated across a wide range of applications. With Ansys Fluent, you can create advanced physics models and analyze a variety of fluids phenomena—all in a customizable and intuitive space.

Accelerate your design cycle with this powerful fluid simulation software. Ansys Fluent contains the best-in class physics models and can accurately and efficiently solve large , complex models.

July 2025

In 2025 R2, Ansys Fluent continues to deliver critical enhancements to improve solver performance, end user productivity, and workflow speeds.

The Ansys Fluent native-GPU Solver in 25R2 features improved physics and new models. Surface-to-surface radiation modeling is now 2-2.5X faster. The FGM model is compatible with conjugate heat transfer, enabling combustion analysis in liner walls, while electric potential and Joule heating capabilities are newly available for advanced applications.

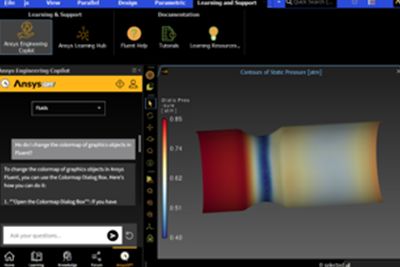

Ansys Engineering CoPilot—a secure virtual assistant—is now available directly within the Ansys Fluent Desktop interface. Engineering CoPilot leverages 50 years of Ansys technical knowledge and experience to help you with your workflows, answer questions, and provide access to training and support directly within your Ansys Fluent software.

Improvements have been made to aerospace and defense workflows. The Fluent Aero Workspace now offers parametric mesh studies and automated post-processing. Manual effort for ablation modeling for high-speed aircraft is reduced. The virtual blade model can be automated via PyFluent, and an unlimited number of rotors are available.

Ansys Fluent unlocks new potentials for CFD analysis. A fluid simulation software with fast pre-processing and faster solve times to help you be the fastest to break into the market. Fluent’s industry leading features enable limitless innovation, while never making a compromise on accuracy.

Explore the best fluid simulation tools on the market in an efficient, customizable workspace

ANSYS FLUENT RESOURCES & EVENTS

Ansys developed a new turbulence model family called Generalize k-w (GEKO) model with the goal of turbulence model consolidation. GEKO is a two-equation model, based on the k-w model formulation, but with the flexibility to tune the model over a wide range of flow scenarios.

This report is intended as an addition to the code-specific Theory and User Documentation available for both Ansys Fluent and Ansys CFX. That documentation describes in detail how to select and activate these models, so that information is not repeated here.

The goal of this paper is to guide a user through the process of optimal RANS model selection within the Ansys CFD codes, especially Ansys Fluent and Ansys CFX.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.