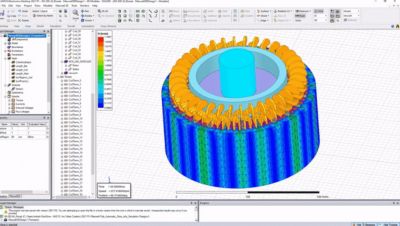

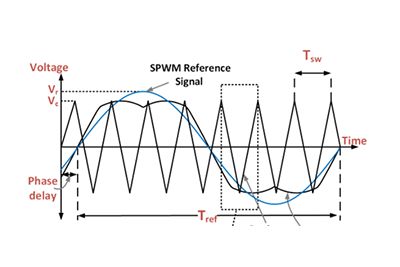

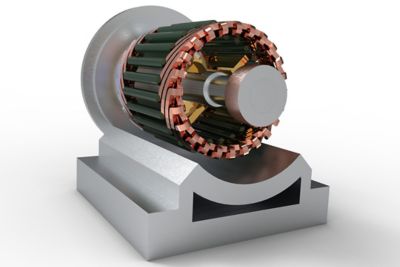

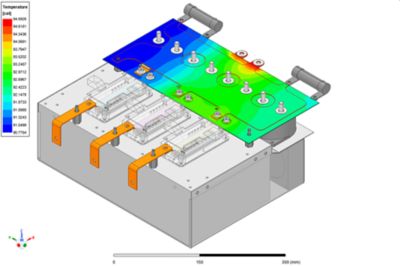

Power Electronics Expert (PExprt) is a magnetic design and optimization tool for ferrite transformers and inductors including, multi-winding transformers, coupled inductors, and flyback components. PExprt's template-based interface for transformers and inductors can automatically create a design from voltage waveform or converter inputs. The auto-design process considers all combinations of core shapes, sizes, materials, gaps, wire types and gauges, and winding strategies to optimize the magnetic design.

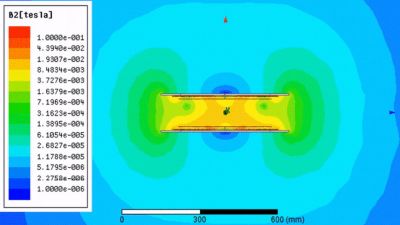

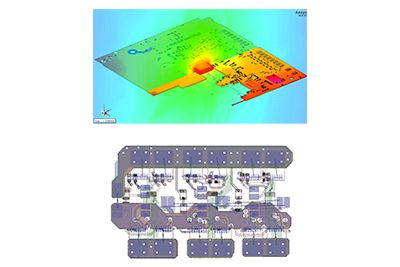

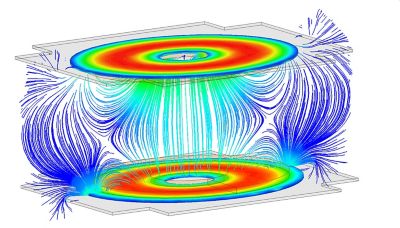

It contains manufacturer libraries for common components. It also combines FEA-based solutions to include skin and proximity effects, and gap effects due to magnetic fringing. Additionally, it calculates winding losses, core Losses, R, L, C parameters and temperature rise, and couples to Simplorer using a frequency dependent netlist for the simulated component.