Quick Specs

Speos has been assessed by the International Commission on Illumination (CIE) against CIE 171:2006 test cases, assessing the accuracy of light modeling software and showing the performance benefits of Ansys Speos.

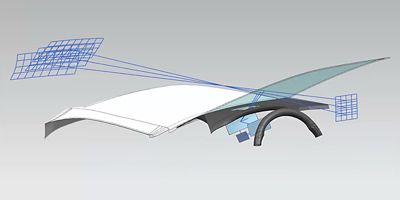

Ansys Speos predicts the illumination and optical performance of systems to save on prototyping time and costs while improving your product’s efficiency.

Ansys Speos delivers an intuitive and comprehensive user interface, enhanced productivity with use of GPUs for simulation previews and easy access to the Ansys multiphysics ecosystem.

Speos has been assessed by the International Commission on Illumination (CIE) against CIE 171:2006 test cases, assessing the accuracy of light modeling software and showing the performance benefits of Ansys Speos.

July 2025

The latest release of Ansys Speos delivers powerful advancements in productivity, GPU-accelerated simulation, immersive visualization, and support for autonomous systems.

Speos simulations can run through cloud compute resources managed by Ansys, enabling HPC capabilities and drastically reducing turnaround time for optical simulations without investing in hardware

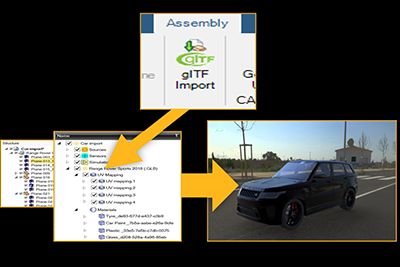

Support for glTF format import simplifies the integration of rich 3D models and environments, making it easier to bring visualization assets into Speos simulations.

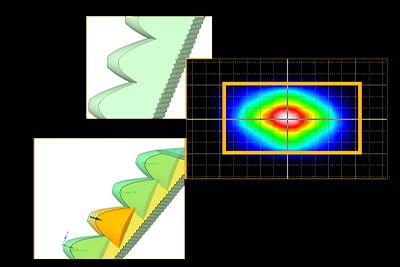

A new total internal reflection (TIR) lens feature supports inner-face-based modeling in interactive layout mode, enhancing the design of compact, high-efficiency lenses such as collimators or edge-lit optics.

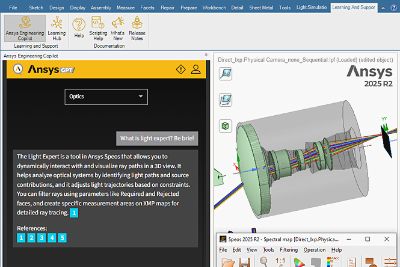

Integrated with Ansys Speos, the Ansys Engineering Copilot serves as a platform to access multiple technical support and learning tools, as well as AnsysGPT™ virtual.

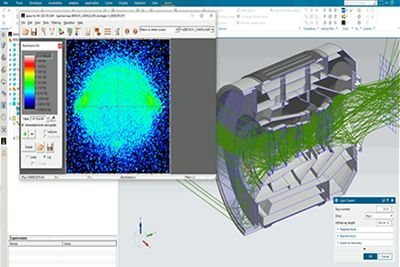

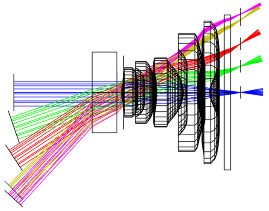

Users can now separate the contributions of the different optomechanical parts of a lens objective, for instance, improving the overall stray light analysis workflow in Speos for NX.

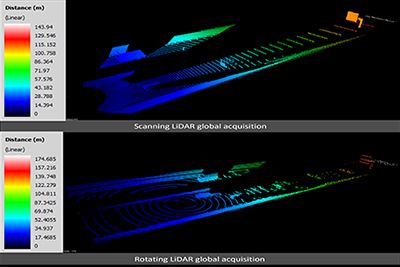

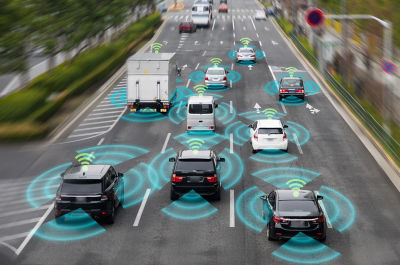

LiDAR Simulation Using Scanning and Rotating Sensors (Speos for NX) supports scanning and rotating LiDAR sensor simulation in Speos for NX, enabling accurate virtual testing of autonomous systems with dynamic sensor behaviors and environment interaction.

A new generation of MAZDA3 uses Speos 3D optical analysis for development of interiors and lights.

The making of the all-new MAZDA3 required a fresh way to judge illumination recommendations and perform analysis. This involved evaluating actual light illumination early in the development cycle, leading Mazda to Ansys Speos. With Speos, Mazda reduced, on average, the number of $95,000 vehicle prototypes per project by three, all while finding a more optimal interior design.

The Speos solution helped Mazda accurately analyze — in a single simulation — light amount and wavelength, accurately analyze reflective properties and reproduce and quantify luminance distribution in two dimensions, allowing Mazda to perform simulations without sacrificing accuracy. By incorporating Speos, Mazda has a better end product and is more involved in detailed design choices earlier in the process. Mazda engineers can optimize features for mass production, saving time and money, and can work with suppliers via Speos simulations to determine exact specifications for a more efficient development process.

CAPABILITIES

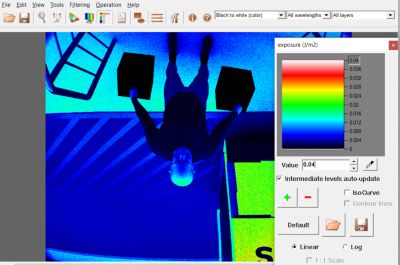

Turn on the light in your virtual model and intuitively explore the propagation of light in 3D. The Speos Live preview function features simulation and rendering capabilities so you can design products interactively. Cut iteration time and speed up your decision-making process by performing simulations correctly the first time, automatically designing for optical surfaces, light guides and optical lenses. To match your performance specifications, Speos combines powerful light analysis capabilities with illumination evaluation across the electromagnetic spectrum, allowing for high-fidelity visualization based on human vision capabilities. Deploy these visualizations in virtual reality for a fully immersive review experience.

Ansys Speos optical design software uniquely simulates a system’s optical performance and evaluates the final illumination effect, based on human vision.

Speos RESOURCES & EVENTS

Join us for a groundbreaking webinar on virtual prototyping in CMOS image sensor design and validation.

This webinar introduces a systematic approach using Ansys optics simulation tools to analyze stray light from both optical and non-optical components.

Join Ansys Senior Application Engineer Christophe Weisse on October 12th to demonstrate how OpticStudio's Contrast Optimization capability solves these problems by providing an alternative method for optimizing MTF.

In this webinar we demonstrate how our best-in-class optical tools, including Zemax, Speos, and Lumerical, can work together for interoperability workflows in the design of an AR system requiring precise subwavelength photonic components, characterization of optical components, and analysis of human vision.

In this webinar we review the latest feature updates in: Productivity Enhancements, Speos GPU Acceleration, Results Experience, Sensors and Autonomy, Optical Part Design and Ansys Integration features.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.