-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

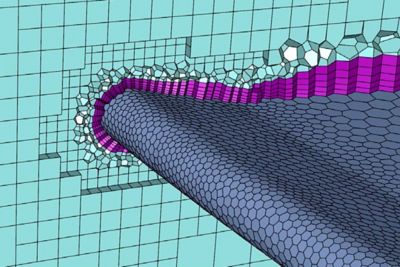

Ansys Fluent Mosaic Meshing

Hexahedral Dominant Mesh Topology

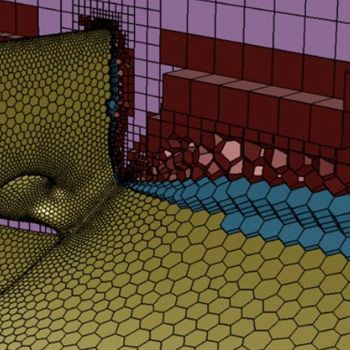

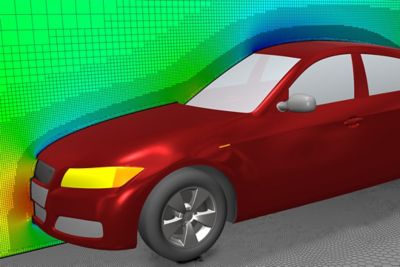

Ansys Mosaic meshing technology helps accelerate meshing time, which also produces a faster, more accurate solution. Mosaic technology enables polyhedral connections between disparate mesh types.

ACCELERATE MESHING TIME

Ansys Mosaic Meshing

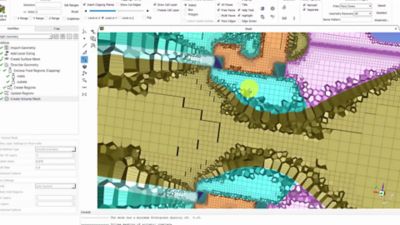

Mosaic mesh is a patent pending Ansys Fluent meshing technology for computational fluid dynamic simulations. It accelerates the meshing process with a reduced face count, higher quality cells and efficient parallel scalability. Mosaic meshing technology enables polyhedral connections between disparate mesh types.

-

Hexahedral Dominant Bulk

-

Lower Total Face Count

-

Lower Memory Usage

-

Parallel Volume Mesh

Video Title

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

Up to Speed

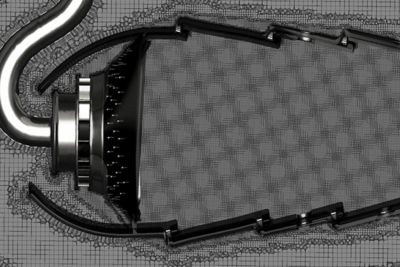

Ferrari Competizioni GT leverages next-level, automated meshing capabilities from Ansys Fluent to increase simulation productivity by 300%.

"Ferrari engineers can run three times as many CFD simulations in the same amount of time — and develop cars faster than ever before."

Ferrari engineers work constantly to optimize aerodynamics and other aspects of vehicle designs, with the goal of crossing the finish line first and reinforcing Ferrari’s brand leadership. Every two or three years, the Ferrari Competizioni GT engineering team pushes itself to engineer an upgraded GT race car within a 12-month window.

Innovations in Ansys Fluent such as Mosaic meshing have enabled tremendous workflow and productivity benefits for Ferrari Competizioni GT. Automated workflows help boosts productivity by reducing the user learning curve, minimizing the chance of human error and freeing engineers to focus on higher-value work. Thanks to Mosaic-enabled poly-hexcore meshing, Ferrari engineers have been able to decrease the number of meshing cells by 15%. This reduction, when combined with the new hex-dominant mesh, delivers overall solution times that are twice as fast.

Video Title

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

Generate a High-Quality Volume Mesh at Unmatched Speed

With Mosaic mesh, you can transition between varying types of mesh elements. Ansys Fluent has created this patent pending technology to help accelerate meshing time. Mosaic enabled poly-hexcore is the first method to employ the mosaic meshing technology, which connects isotropic poly prisms and hexahedral elements.

Key Features

Mosaic enabled poly-hexcore is the first method to employ mosaic. This technology has many benefits for computational fluid dynamics simulations, from meshing to solving.

Mosaic enabled poly-hexcore mesh uses high-quality hexahedral elements in the bulk region. Since the volume is generated with hexahedral elements, for the same grid resolution there is a total face count reduction.

Fluent meshing allows for parallel volume meshing on up to 256 cores. When running on 256 cores, over 10 million cells can be generated per minute. Parallel meshing, along with the lower overall mesh counts from Mosaic mesh help accelerate the meshing process.

Since Mosaic enabled poly-hexcore mesh uses hexahedral elements in the bulk region, for the same grid resolution there is a total face count reduction. This total face count reduction helps result in faster compute times. 30-50% reduction of solve times have been seen.

MOSIAC MESHING RESOURCES & EVENTS

Featured White Paper

Videos

Ansys Fluent Mosaic Meshing for CFD Simulations

Mosaic from ANSYS brings artistic expression to engineering simulation. An all-new meshing technology for Fluent simulations, Mosaic automatically combines any type of boundary layer meshing with high-quality polyhedral meshes for fast and accurate flow resolution. This powerful, new Fluent experience can deliver better quality cells 45 percent faster, while requiring 30 percent less memory. ANSYS Fluent now easily and quickly transitions between varying types of mesh elements in complex geometries and flow regimes, allowing you to explore more materials, more parts, more possibilities.

Ansys Video

Ansys Fluent Mosaic Meshing for CFD Simulations

Brochures

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.