What's New

Register for one of our upcoming webinars to learn how Ansys simulation solutions contribute to the technology trends and application areas most relevant to the A&D industry.

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Students get free access to world-class simulation software.

Connect with Ansys to explore how simulation can power your next breakthrough.

The A&D industry has been at the leading edge of developing and adopting simulation technology since the introduction of computerized tools. Explore the latest simulation innovations for Aerospace & Defense.

Register for one of our upcoming webinars to learn how Ansys simulation solutions contribute to the technology trends and application areas most relevant to the A&D industry.

AGI Golden Dome Webinar Series: 5-part Series

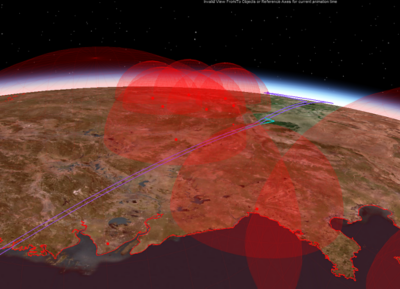

America’s “Golden Dome” air and missile defense initiative will require advanced capabilities to detect, track, and defeat potential aerial threats including intercontinental ballistic missiles (ICBMs), hypersonic missiles, cruise missiles, unmanned aerial systems, and others. If you are developing systems to support Golden Dome, you will not want to miss our five part series! NOTE: This webinar series is open to U.S. persons only.

Register Now

Space Mission Analysis and Design Webinar Series

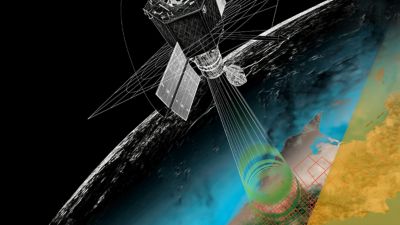

Join our comprehensive Space Mission Analysis and Design webinar series, where Ansys experts and guest speakers from industry will guide you through cutting-edge simulation technologies transforming modern spacecraft development. This multi-session program explores how integrated Ansys solutions address the unique challenges of space systems engineering.

Learn More

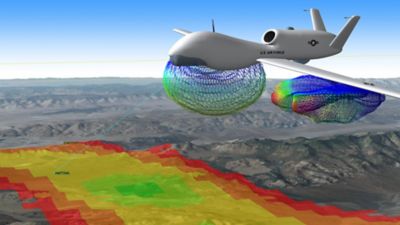

Digital Mission Engineering: Air Systems

Learn about the emerging challenges in air systems and mission design with an analysis of the limitations of legacy approaches. Find out how DME reduces discontinuity across modeling and simulation efforts throughout the design lifecycle.

Learn More

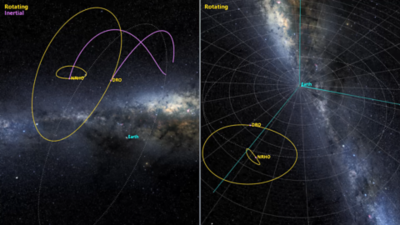

Trajectory Modeling and Cislunar Space: 5-part Series

Cislunar missions have the potential to drive scientific progress, technological innovation, and economic growth, making them an important focus for space exploration in the coming years. Trajectory modeling in cislunar space will play an important role in the success of these missions. Avoiding collisions with other objects in space, optimizing fuel consumption, and ensuring that spacecraft arrive at their destinations on time and on course are just a few objectives of trajectory modeling.

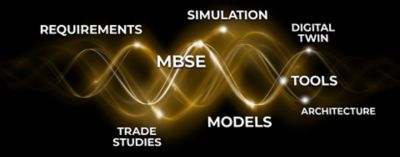

Learn MoreSimulation is essential to successful digital engineering as it accelerates innovative leaps, reduces costs, and mitigates risks, enabling the organization to create better products faster.

Advancements in air mobility, enabled by autonomous systems and electrification, transform how we think of short-distance flight. Simulation is essential to designing these new technologies and coordinating the vehicles that rely on them.

Autonomous Systems Webinars

Simulation enables quality, safety, reliability, and cybersecurity analysis methods at the system, item, software, hardware, and PCB levels.

Most defense systems rely on the EM spectrum, which is increasingly congested, constrained, and contested. The need to address known and unknown vulnerabilities has never been more critical.

Spectrum Operations Webinars

Advancements in propulsion systems that make aviation safe, quiet, efficient, and clean