-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TOPIC DETAILS

What is Diffractive Optics?

Physics laws of optics and photonics can be used to model the propagation of light. Conventional reflective and refractive optics, also known as geometric optics, describe light as a ray that can be reflected, refracted, diffused, or absorbed by optical materials (like polished glass, colored frosted plastic, human skin, matte white paint, etc.).

Conversely, diffractive optics describes light as an electromagnetic wave. Light diffraction happens when light waves encounter microstructures (micro-optic elements) or openings comparable in size to their wavelength. When light diffracts through these structures, which can be just hundreds of nanometers in size, the light beam can be focused, shaped, redirected, or split.

What are Diffractive Optical Elements?

The components that manipulate light properties through diffraction are called diffractive optical elements (DOEs). Some of those elements are used within optics today, like diffraction gratings, and others are new and seen as the next generation of optical lenses (e.g., metasurfaces and metalenses).

DOEs offer precise control over the phase, polarization, and intensity of light waves, making them highly desirable. They are also much thinner and lighter compared to traditional refractive optic elements, which can reduce the size, weight, and cost of optical systems.

Conventional Diffractive Optical Elements

There are many popular types of DOEs used in manipulating light sources. These include diffraction gratings, Fresnel zone plates, diffractive beam splitters, diffractive beam shapers, and diffractive diffusers.

Diffraction Gratings

Diffraction gratings are optical structures made with very small, periodic patterns in which the distance between them is as small as a light wavelength (i.e., in the range of micrometers or nanometers). These patterns can redirect incident light into multiple spatial directions called diffraction orders. Diffraction gratings are used in many applications, from spectroscopy to augmented reality (AR) glasses.

Surface relief grating (SRG) and volume holographic grating (VHG)

There are two types of diffraction gratings:

- Surface relief gratings

- Volume holographic gratings

Surface relief gratings contain small, periodic grooves that are mechanically fabricated using diamond turning, 3D printing, or lithography. The grooves in each type of grating are different, enabling designers to tailor the grating to the intended application and wavelength range. These grooves are responsible for manipulating the light. Changing the periodicity and structure changes the grating’s diffraction efficiency and diffraction order. This enables better control when manipulating light.

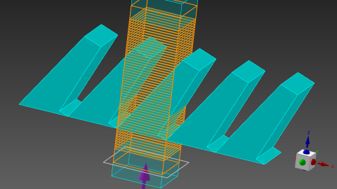

Simulation of a 2D blazed grating in transmission with the rigorous coupled-wave analysis (RCWA) solver in Ansys Lumerical FDTD software.

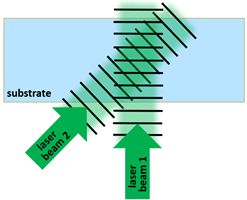

Volume holographic gratings are fabricated by recording a holographic pattern within a photosensitive material. First, a photosensitive material (i.e., a polymer or glass) is exposed to an interference pattern created by two coherent laser beams. This forms a three-dimensional modulation of the refractive index within the substrate material.

When light hits the grating at one of the original recording angles, it reproduces the second recording beam used during the process. The bandwidth of the response depends on the material, modulation index, and grating thickness.

Formation of a volume holographic grating (VHG)

When the grating is illuminated by laser beam 1, it reconstructs laser beam 2 as the output beam.

Fresnel Zone Plates

Fresnel zone plates consist of circular gratings with a radially increasing line density (i.e., rings that get closer together toward the outer edge). The concentric gratings alternate between transparent and opaque. Light hitting the transparent ring is transmitted, whereas light hitting the opaque ring is diffracted. The spacing between the rings determines how the diffracted light interferes, focusing it to form an image. Fresnel zone plates can be used across different wavelengths, making them valuable in many applications like X-ray imaging, spectroscopy, photography, and telescopes.

Diffractive Beam Splitters

Diffractive beam splitters are gratings that split an incident light beam into multiple beam outputs, or diffraction orders. Each output beam retains the same optical characteristics as the input beam. These devices are typically used with monochromatic light in devices like laser beams, and they are designed for specific wavelengths and diffraction angles.

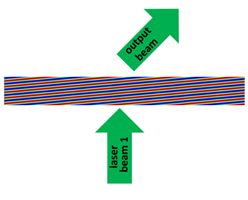

Simulation of a diffractive beam splitter

Diffractive Beam Shapers

Diffractive beam shapers change the phase profile and intensity of laser beams with a Gaussian intensity profile — that is, a brightness pattern in which the beam is strongest at the center and gradually decreases toward the edges in a smooth curve. Diffractive beam shapers manipulate characteristics of the input beam to change the shape of the output beam. The output is usually circular or rectangular, but other beam geometry profiles can also be obtained. Diffractive beam shapers are used in lithography, holographic lighting, optical sensors, biomedical applications, and laser material processing.

Diffractive Diffusers

Diffractive diffusers also convert an incident laser beam into multiple output beams, but the main difference is that these beams overlap and interfere with each other to create a homogenized distribution. They typically consist of specific patterns of microstructures that determine how light is diffracted and distributed. Engineers can design these micrometric structures to achieve distinct illumination patterns (e.g., circular, square, or cross).

Diffractive diffusers are used to homogenize a light source and spread a narrower beam into a broader range of angles without the limitations of traditional refractive optical components. Applications include machine vision systems to provide uniform illumination for better image capture; displays to improve viewing angles; flash lidar to spread laser beams uniformly to a wide area; and scanning lidar for controlling how much the laser beam spreads out, which is also known as the diffusing angle.

Advanced Diffractive Optical Elements

Alongside the established DOEs, a new class of advanced diffractive optical components is emerging to represent the next generation of optical technology. These are created using advanced semiconductor fabrication techniques such as nanoimprinting and lithography. Two of the most important advanced DOEs today are metalenses and grating couplers for photonic integrated circuits (PICs).

Metalenses

Metalenses are composed of millions of meta-atoms ― nanoscale structures with varying shapes and sizes ― positioned across a substrate to form a lens. The size and position of the meta-atoms on the surface change how light waves are redirected. Metalenses offer a very thin alternative to traditional bulky lenses, as they are about as thin as a strand of hair and much more compact. They are incredibly lightweight, making them ideal for portable devices. Additionally, metalenses can be manufactured using processes and equipment already used for mass-producing semiconductor chips.

Metalenses can also focus or filter out specific colors or wavelengths, significantly reducing chromatic aberration. These benefits make metalenses a promising replacement for traditional refractive lenses in many applications, including projection systems in augmented reality glasses, thin and compact double-way imaging/projection lenses for endoscopes, and imaging cameras in cell phones and drones.

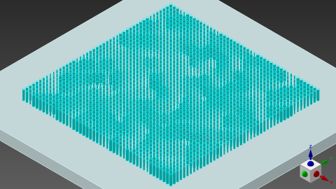

A metalens simulation in Ansys Lumerical FDTD software. The meta-atoms are shown as extruded rods varying in size and position.

Grating Couplers for Photonic Integrated Circuits

Another area is co-packaged optics, which describes an integrated system that consists of optical components and silicon on a packaged substrate. Co-packaged optics are positioned to address the power and bandwidth challenges of modern-day electronics, and they are considered a major stepping stone for the development of photonic integrated circuits. Some key applications include augmented reality, virtual reality, image sensors, and optical communications.

Co-packaged optics enable you to couple two waveguides of different sizes (an input and an output), in which light is transferred from one waveguide to another with low attenuation, or minimal signal loss. These junctions are expected to become the building block of PICs, replacing electronic components with photonic components. PICs are expected to be highly sought after in the future because light travels faster than the speed of an electron, meaning that circuits could theoretically operate much faster with higher data transfer speeds.

How are Diffractive Optical Elements Simulated and Designed?

The complexity and small scale of diffractive optical elements make them ideal candidates for 3D electromagnetic simulation software. For example, with metalenses, simulations can help researchers examine the position and size of meta-atoms to simulate the diffraction of light through different arrangements. Simulations can help designers analyze field distribution, far-field patterns, and changes in wavefronts when manipulated by a diffractive optical component.

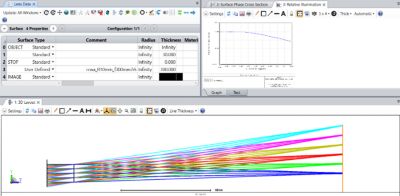

Ansys Lumerical suite, Ansys Speos software, and Ansys Zemax OpticStudio software can simulate diffractive optical components. Individual components can be designed using the FDTD and RCWA solvers in the Lumerical suite, and a DOE’s performance can be analyzed in OpticStudio software. These software packages enable you to simulate either a single lens or multiple lenses simultaneously.

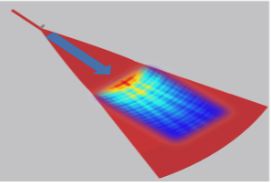

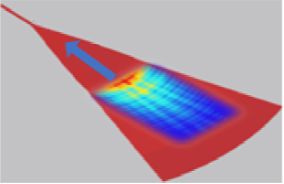

Light propagation and coupling from an optical fiber to a waveguide, thanks to a grating coupler and a microlens

Animated spectral conoscopic map in Speos software using the Lumerical subwavelength model plugin to simulate the diffracted reflection of a variable incident light

Designing and Simulating a Metalens

Simulation software can show how light passes through a metalens with different meta-atom arrangements and sizes, and then export the design data for fabrication. These simulations can be used to develop lenses for augmented reality and compact projector applications. Multi-GPU setups in Ansys software can accelerate simulation performance by combining the memory and processing power of several GPUs, enabling you to simulate large metalens systems containing millions of meta-atoms.

Metalens simulation in OpticStudio software with the Lumerical metalens plugin

Simulating Co-packaged Optics

Co-packaged optics simulations from the Lumerical suite can model how light propagates through a waveguide and demonstrate how its shape is important in splitting and directing light waves. These digital models illustrate how co-packaged optics can support the development of PICs. Optics simulations can also help designers evaluate how effectively diffraction gratings can couple light into waveguides and show how wave propagation can be modified to fit the shape and size of subsequent waveguides. Further, they can model how wavefronts can be combined to form a specific pattern.

Co-packaged optics grating coupler in-out design

What’s Next for Diffractive Optics?

Metalenses and co-packaged optics support the development of many technological advancements, including:

- Cell phones and cameras that are thinner and more compact

- Metasurfaces that can replace CMOS image sensor microlens arrays and Bayer color filters

- Light and compact augmented reality glasses with a brighter and crisper picture

- Photonic components that can replace traditional electronic components for faster communication

- Advanced healthcare optic technologies including confocal laser scanning microscopy, optical coherence tomography (OCT), endoscopes, and intraocular lenses

Ansys software tools help companies improve their designs well before fabrication has begun. Tools such as Lumerical suite that support diffractive optical component design are already popular among academics and are used by many global corporations to improve their products.

To elevate the design and fabrication of your diffractive optical components and get ahead in the market, contact our technical team.

Related Resources

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.