Quick Specs

Reduce time-to-market with the industry-leading engine modeling software. Utilize a fast chemistry solver to predict ignition, emissions, fuel effects and soot.

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

Ansys is committed to setting today's students up for success, by providing free simulation engineering software to students.

For United States and Canada

+1 844.462.6797

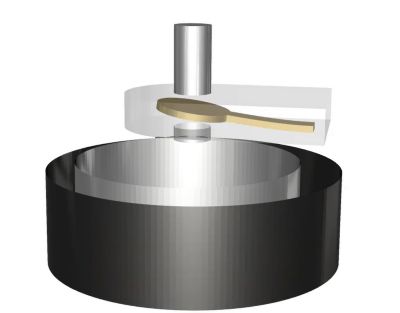

Ansys Forte is a computational fluid dynamics software for modeling internal combustion engines and positive displacement compressors. Accurately and efficiently model your engine or compressor with state-of-the-art chemistry and meshing.

Ansys Forte incorporates the proven Ansys Chemkin-Pro solver technology for validated gas phase and surface chemistry. This positive displacement compressor and internal combustion engine design software can quickly and accurately predict performance and design improvements. Streamlined workflows and automatic mesh generation reduce hands on time, enabling more time to reach optimal design ideas.

Reduce time-to-market with the industry-leading engine modeling software. Utilize a fast chemistry solver to predict ignition, emissions, fuel effects and soot.

July 2024

In 2024 R2, Ansys Forte software updates include workflow speed-ups, efficiency improvements, and updated best practices available for several applications.

A new default for the unburned calculation method improves simulation speeds in cases that use high mesh resolution in the spark plug region.

Users can now automatically minimize the flow leakage across small gaps for compressor and pump applications to improve accuracy and realism. Automation is also available to determine the surface proximity to better identify and eventually model the gap regions.

The new guidance is now available for engine simulations, system coupling analyses, generic compressor simulations, surface mesh handling, operating environment recommendations, EnSight post-processing, and more. The Ansys Forte Help Site documentation provides best practices and user guides.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.