Overview

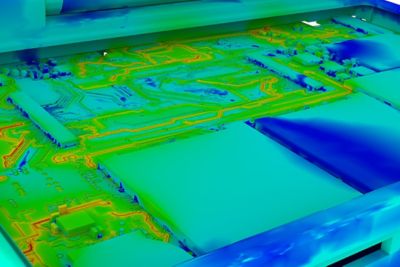

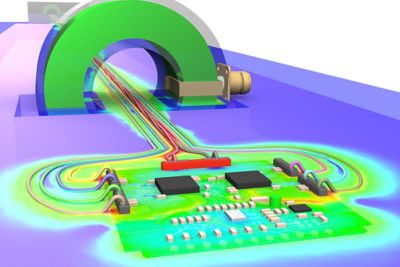

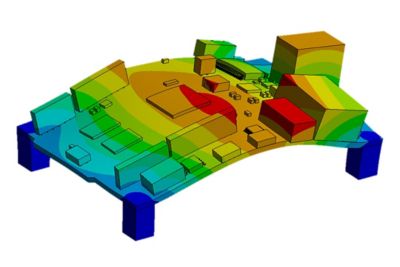

The Internet of Things represents a staggeringly complex ensemble of interconnected products, devices and systems. Each component and subcomponent in the system affects and is affected by all the others. To ensure cost-effective and timely development, successful engineering of IIoT products relies on numerous applications, including antenna design and placement, chip-package system development, power electronics, electromagnetic interference/compatibility (EMI/EMC), electronics reliability and battery simulation.