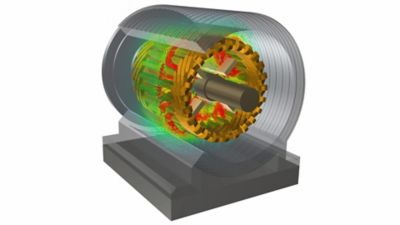

Applications

The extraordinary design challenges posed by mobility electrification require equally extraordinary solutions. Simulation is the only way to efficiently address the design demands that will define a successful race to market. Electric mobility leaders are already reporting on the benefits of electric vehicle simulation software and its empowering effect on the design process.