-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

If you were to get a sneak peek at the future of the aviation industry, what would you see? One possible answer to this question is an increased reliance on certification by analysis (CbA).

CbA — also known as certification/quantification by analysis (CQbA) — is a method of demonstrating compliance with regulatory requirements for airplane and engine certification. It is based on a building block approach approved by aerospace authorities, which validates results from a series of small parts ("blocks") before moving on to large assemblies.

The potential applications of CbA are widespread, ranging from aiding in developing hardware systems to software and systems integration.

The adoption of CbA will occur through three stages: development supported by analysis (stage 1), certification supported by analysis (stage 2), and certification by analysis (stage 3). The industry is currently in stage two, and while achieving stage three is the next goal, it will not be easy.

Major Challenges in the Current Aircraft Certification Process

Without a doubt, safety is the top priority for both aircraft developers and passengers alike. Achieving such safety is not easy, though. This involves ensuring that every single component and system used in an aircraft is optimized for safety.

To aid in this goal, thorough and stringent requirements must be created to ensure such safety, which has resulted in many physical performance and certification tests for aircraft manufacturers.

These physical tests, which analyze everything from controllability, maneuverability, and stall characteristics to aircraft engine durability and weight limits, have a few widely recognized challenges.

- Physical flight and engine tests are expensive. In fact, aircraft certification can require an investment of $1-2 billion, which varies based on whether the test involves a derivative or a new aircraft.

- Real-world testing is a lengthy process. Managing extensive compliance lists and new regulation items adds significant complexity — even a single certification test can require a significant time commitment. The time it takes to reach certification can also be extended by uncontrollable factors, such as waiting for ideal weather conditions or the availability of specific testing facilities.

- Uncertainty and retesting can result in considerable financial and time losses. If certification requirements are not met or there is any physical test uncertainty, designers may incur additional delays and costs to redevelop or redesign the airframe or engine. Additionally, certification is not guaranteed upon completion and can be suspended in cases such as a crash or a failure. In such instances, companies may have to pay penalties and additional costs to fix underlying issues and recertify their designs. Developers must achieve compliance, so these costs are unavoidable if flaws are found.

- Physical testing can be dangerous. Real-world tests require extensive training and safety procedures to implement.

- New and evolving certification requirements are constantly being introduced. Engineers and manufacturers must continually and rapidly adapt to these changes. New amendments may be needed that take new details or risks into consideration. For example, aircraft developers may need to change approaches to account for factors like the icing risk of supercooled large drops (SLDs), which would require raising their initial tested droplet size from 50 microns to up to 1 mm.

So, what’s an aircraft manufacturer to do? To address these issues and reduce costs while still prioritizing safety above all else, manufacturers in the aerospace industry can turn to CbA to demonstrate regulatory compliance.

CbA, Digital Engineering, and Simulation

When used in the aerospace industry, CbA has many benefits that can be achieved while maintaining equivalent levels of safety and security:

1. Streamlined product certification testing that can shorten time to market

a. Minimized physical testing time, a smaller number of flight tests required during certification, and a lowered risk of surprises during physical tests (which can cause delays and other costs)

b. Time savings from including the design process as well as knowledge and data management in one place

c. Decreased downtime from using digital twins for predictive maintenance

2. Reduced overall costs in the certification and compliance testing stages

a. Potential savings of $300 million or more while maintaining safety and performance goals

b. Identification and avoidance of costly issues early in the development process

c. Possibly cheaper products for airlines, as well as lower expenses for travelers due to reductions in testing and certification costs

To fully realize these benefits and fully implement CbA, predictive analysis tools must achieve rigorous, credible, robust, and accurate results. Further, such a tool needs to generate results in a computationally efficient manner to ensure that safety requirements are fully attained. Increased confidence in CbA itself is another crucial step toward widespread adoption.

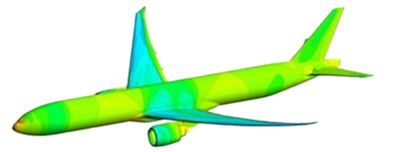

One existing technology that looks to be a solution for achieving this reliability and implementing CbA in the wider aerospace and defense (A&D) certification process is Ansys modeling and simulation software.

Using Ansys’ portfolio, A&D innovators can access solutions that will help them generate imperative data needed throughout the certification process. In particular, Ansys’ multiphysics solutions enable users to address a wealth of individual physics and couple these physics to achieve better accuracy. This enables CbA to meet regulatory requirements that maintain essential accuracy in areas such as aircraft structures, engines, flight, and software.

Looking ahead, CbA addresses a well-known need and is a major opportunity for the A&D industries. Simulation-powered CbA has the potential to yield better-performing aircraft and new aviation technologies quicker and with less cost and risk.

To learn more about this potential and how organizations already use simulation in their certification process, check out the Certification by Analysis: Transforming Aircraft Component Compliance Through Digital Engineering.

Just for you. We have some additional resources you may enjoy.

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.