-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

March 27, 2024

Podcast Spotlights Simulation’s Impact on Advancing Clean Hydrogen Solutions

With increasing concerns about climate change, carbon dioxide (CO2) emissions, and other environmental pollutants, more industries around the world are looking toward hydrogen as a cleaner alternative to fossil fuels.

Hydrogen fuel offers zero CO2 emissions when produced using renewable energy sources to power the electrolysis of water to release hydrogen. Hydrogen production, however, also poses challenges and concerns, including safety, cost, and scalability.

Engineering simulation has gained attention as being one of the optimal ways to improve clean hydrogen production by developing new and existing technologies. In fact, the International Energy Agency (IEA) states that net-zero emissions are not even achievable without robust research and development (R&D) efforts in key technologies.

Recently, a U.K.-based media platform invited Ansys to discuss how simulation is driving innovation in this space on its podcast Hydrogen Industry Leaders (HIL). The platform aims to provide insight into how hydrogen solutions can be developed as we move toward a net-zero world. In an episode dedicated to simulation, Pepi Maksimovic, an Ansys Customer Excellence distinguished engineer, discussed how physics-based simulations deliver critical insights during R&D in hydrogen production, helping to ensure safety and build confidence in technology, drive down costs, and increase scalability.

Pepi Maksimovic, distinguished engineer, Ansys Customer Excellence

Listen to the "Physics-Based Simulations and the Role They Play in Growing the Hydrogen Economy" episode of the Hydrogen Industry Leaders podcast below.

Simulating Safer Energy Transformation

The HIL podcast series welcomes experts from around the world to share their views. With each episode focused on hydrogen production, safety, storage, and related topics, the podcast presents an opportunity to discover how different industries and sectors are advocating for green technologies to transform the energy sector.

Ansys’ Maksimovic joined HIL host Floyd March to discuss the role of simulation in episode 23: Physics-Based Simulations and the Role They Play in Growing the Hydrogen Economy. Backed by data and science, physics-based simulation helps engineers analyze and test hydrogen production processes with specific consideration to engineering dynamics such as thermal, fluid, chemical, and structural behavior. In this way, simulation helps R&D teams safely test and analyze phenomena that they otherwise couldn’t examine while also leveraging virtual testing on computers to reduce the cost and time required for physical testing and prototyping.

Green hydrogen is sustainably produced through the electrolysis of water, excluding the use of fossil fuels.

Current energy transformation goals are rooted in the need to transition from fossil fuel-based energy solutions to zero-to-low-carbon solutions such as renewable energy, nuclear energy, and hydrogen. To achieve this transformation, the IEA has emphasized the importance in technology development, citing that almost 35% of the CO2 emissions reductions seen in its projected Sustainable Development Scenario by 2070 come from technologies that are either at the prototype or demonstration level, unable to advance at scale without further R&D. The IEA also asserts that another 40% of these targeted emissions reductions rely on technologies that are not yet commercially available in mass‑market applications.

Maksimovic explained how simulation is being used to address these two main objectives: to improve the existing technology, as well as to develop and accelerate development of brand new technologies through the R&D innovation.

Beyond production, simulation optimizes the remainder of hydrogen’s value chain, including storage, distribution, and utilization, through in-depth analyses that ensure optimal performance, safety, and environmental outcomes.

Overcoming Hydrogen Hurdles with Simulation

The production cost of green hydrogen — which eliminates the use of fossil fuel altogether — has remained prohibitive for large-scale adoption. As engineers and R&D teams explore ways to improve production capacity, efficiency, and cost competitiveness of carbon-free, green hydrogen, other low-emission hydrogen alternatives are being pursued in parallel.

An example of this is the application of carbon capture technology to capture and remove carbon emissions created during production of so-called blue hydrogen from fossil fuels.

Other companies are exploring alternatives such as turquoise hydrogen. This form of hydrogen production converts natural gas into hydrogen gas and solid carbon, the latter of which could be used for electric vehicle (EV) batteries instead of creating CO2 emissions.

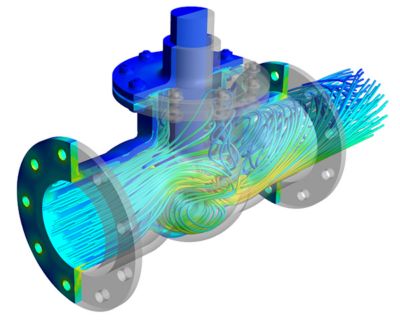

Simulation offers significant R&D support, including predictive accuracy and limitless analysis capabilities. For example, advanced software packages such as Ansys Fluent computational fluid dynamics (CFD) helps R&D teams accurately and efficiently analyze a variety of complex fluids phenomena at the level of detail that often exceeds the capabilities of physical testing. Such phenomena includes heat and mass transfer, chemical reactions and combustion, and others.

Ansys Fluent unlocks new potential for research and development (R&D) in hydrogen production with computational fluid dynamics (CFD) analysis and capabilities.

Maksimovic notes that the widespread industry transition to clean hydrogen production requires time and technology. A wider adoption of clean hydrogen requires significant build up in production capacity and driving costs down to acceptable levels, again underscoring the importance of R&D.

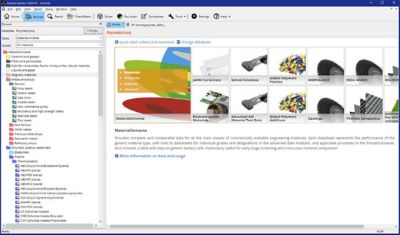

Equipment design is another area in which simulation provides critical insight. Tools like Ansys Granta Selector help engineers and designers improve material selection for technical and environmental performance as well as cost, while Ansys Mechanical enables them to ensure structural integrity of the equipment.

Engineers and designers can explore thermal characteristics during hydrogen production and assess structural integrity throughout equipment design using Ansys Mechanical.

Ansys Granta Selector enables R&D teams to discover more sustainable materials to improve design while upholding environmental standards.

“There’s a lot of simulation opportunities [just] for the electrolyzers themselves … how do you design the optimal cell, how do you stack the cells … understanding the polarization curve … the thermal, the heating?” she said. “So, all those challenges that engineers and designers have to grapple on an everyday basis, essentially … it’s really the crux of simulation ...”

Another hurdle in the broader adoption of hydrogen is fear for safety. While some of this stems from a general unfamiliarity with hydrogen as an energy source, other concerns are more tangible. Due to its high flammability coupled with its lower ignition energy, hydrogen can ignite faster than gasoline or natural gas, which raises safety concerns around potential fire hazards if mishandled. To mitigate these risks, government agencies and regulatory associations administer safety standards regarding its handling, including outlined safe distances from flammable gas storage, sources of ignition, and fuel gas vent pipes. There are additional guidelines in place for safe distances from employee offices or congregations of people.

According to Maksimovic, simulation helps de-risk hydrogen production processes while also easing concerns on a broader scale.

“By having that insight, how things behave, perform … understanding the processes themselves and understanding how the physical equipment will behave … as you’re designing, validating, verifying —doing all that before you bring product to the market — that’s de-risking for product manufacturers,” she said. “But also … there’s de-risking just in general. If people understand how much went on in designing and how much safety is put into it … that also helps the general population, I think, to embrace the use of hydrogen in everyday because everybody wants to use something that is proved to be safe and reliable.”

Looking at Worldwide Hydrogen Adoption

Simulation is being integrated into hydrogen R&D across global markets and industries, including energy, automotive, aerospace, and others.

Maksimovic believes that cost reduction in scaling hydrogen is the key to wider adoption. To this end, some energy government agencies have unveiled target programs to bring down the cost. In the U.S., for example, the Department of Energy’s Energy Earthshots Initiative, also known as the 111 program, aims to reduce the cost of hydrogen to $1 per 1 kilogram in one decade.

To learn more about Ansys’ solutions in this area, visit Empowering the Hydrogen Value Chain Through Simulation.