-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

April 19, 2024

Using the Power of Simulation and Liquid Lenses for Early Melanoma Detection

“Don’t forget sunscreen!”

How often did we hear Mom or Dad yelling at us to put on sunscreen as a child? We might have found it annoying back then, but it was for a good reason. More than one third of Americans report getting sunburned every year. As many of us know, sunburn is not very pleasant. But the pain and itching are the least of our worries. Over-exposure to ultraviolet (UV) rays — either from the Sun or tanning beds — is a major cause of skin cancer. Skin cancer is the most common cancer in the United States, with roughly 5 million people treated every year. There are a few common types of skin cancer, but the most serious is skin melanoma because it can metastasize, or spread, to other areas of the body.

Melanoma starts in the melanocytes, which are the cells responsible for giving our skin its color. Many melanomas start on a mole, but most occur on normal skin. While melanoma only accounts for 1% of skin cancer, it makes up the majority of skin cancer-related deaths. This might sound scary, but melanoma is treatable if caught early through self-checks and regular visits to the dermatologist.

Current screening methods involve total body examinations, checking each individual pigmented lesion for melanoma signs. This can be very time consuming, especially for patients with many moles or pigmentations. In an effort to make early melanoma detection easier and more efficient, the European Union’s Horizon Europe program provided funding for the Intelligent Total Body Scanner for Early Detection of Melanoma (iToBoS) project.

Partners working on iToBoS are developing an artificial intelligence (AI) diagnostic platform to help detect melanoma. The platform includes a total body scanner and computer-aided diagnosis (CADx) tool to integrate patient-specific data such as:

- Age and sex

- Clinical phenotypes: anatomical locations of every lesion and skin phototype

- Genotype: mutations in hereditary melanoma genes and genetic variations in melanoma susceptibility genes

- Imaging phenotype: number and size of moles and the degree and area of UV-damaged skin

- Clinical dermoscopic image: characteristics of the lesions acquired by the high-resolution total body scanner

Combining all this data will provide healthcare professionals with an accurate, detailed, and structured assessment of pigmented skin lesions specific to that patient.

The total body scanner will be based on an existing prototype developed by three of the project partners and powered by Optotune’s high-resolution cameras equipped with liquid lenses. Based on two immiscible fluids of different refractive indexes, these novel lenses provide unprecedented image quality of the whole body. The integration of images with all available patient data using machine learning will lead to a new dermoscopic diagnostic tool that can provide prompt, reliable, and highly personalized diagnostics for optimal judgment in clinical practice.

Changing Focus by Replicating Nature

Founded in 2008, Optotune develops and manufactures several optical components for machine vision, microscopy, laser processing, healthcare, automotive, and other applications. Initially, their core technology was focus tunable liquid lens, inspired by the anatomy of the human eye.

Traditional optics are based on solid glass or plastic lenses, which move back and forth to focus or zoom. Simply put, light passes through the lens and the lens moves back and forth to converge the light to a specific point. If the light converges in front or behind the point, the image is out of focus.

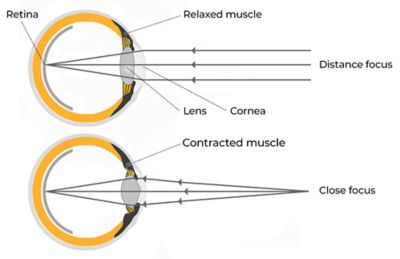

Your eye, however, consists of an elastic lens that bends to focus. When looking at things far away, your eye muscles relax and the lens looks slim. When looking at things close up, your eye muscles contract and the lens gets thicker.

How the eye focuses on near and far objects

Optotune’s focus tunable lenses are based on a container filled with optical fluids sealed with an elastic polymer membrane enabling the change of their shape. A circular ring that pushes onto the center of the membrane shapes the tunable lens. The deflection of the membrane — and with that, the radius of the lens — can be changed by pushing the ring towards the membrane. This process occurs by exerting pressure to the outer part of the membrane or pumping liquid into or out of the container.

Focus tunable lenses have five advantages over traditional optics:

- Compact designs

- Fast response

- High reliability

- Robust system design

- Less tolerance sensitivity

An MRI Scanner for Moles

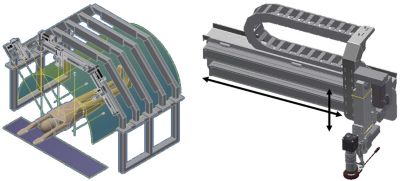

The iToBoS construction is similar to an MRI or CT scanner. The patient lays on a bed with five arches above them. Each arch has three camera modules that can move laterally and vertically. Each camera module has a:

- High-resolution camera.

- Objective lens.

- Lighting system.

- Distance sensor.

Rendering of the iToBoS (left) and the camera module (right)

The lenses had a few parameters they needed to meet in addition to technical specifications.

- Camera distance for patient safety — roughly half a meter.

- Scanner time for patient comfort — typical MRIs take anywhere from 20 minutes to over an hour.

- Small field of view (FoV) for high resolution images — the distance between the camera and patient requires smaller FoVs for the same image quality as if the camera was a few centimeters away.

- Small depth of field (DoF) to account for the 3D object, the patient — stack several images by moving the focus in small steps.

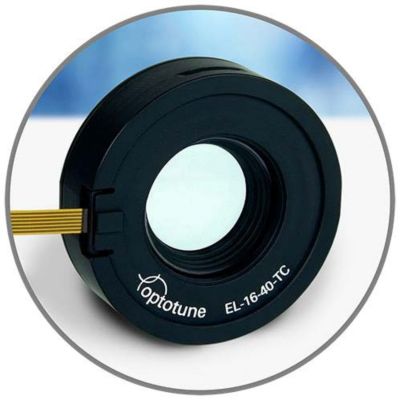

Accounting for all of these parameters, the iToBoS team decided to use the EL-16-40-TC liquid lens from Optotune — a large, electrically focused lens that comes with a compact design.

The EL-16-40-TC liquid lens from Optotune

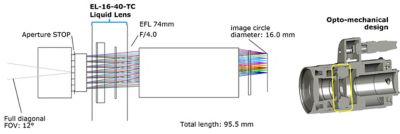

Camera module layout with performance characteristics (left) in Ansys Zemax OpticStudio and the opto-mechanical design of the module with the yellow rectangle indicating where the liquid lens is housed (right)

Testing Requirements in OpticStudio

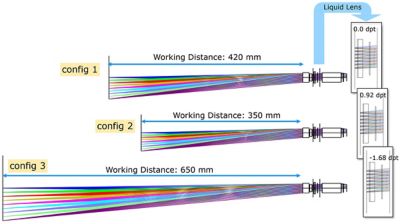

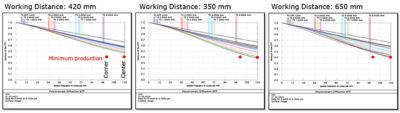

To test the different lens requirements, Optotune turned to Ansys Zemax OpticStudio. When using a liquid lens in an optical design, it needs to be dynamic. In this case, Optotune needed to adjust the distance between the patient and the camera module (called the working distance) from 350 to 650 mm, with an intermediate distance of 420 mm. Unlike other lenses, a liquid lens does not need to undergo a large change in focal power (+1 diopter to -1.7 diopters) to adjust the focus according to these different working distances. The change of the curvature of the liquid lens to adjust the focal strength is minimal compared to the adjustment a fixed lens would make in its own operating environment.

Nominal design of scanner camera with liquid lens simulated in Ansys Zemax OpticStudio

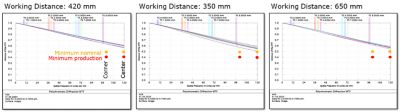

The performance of the lens required distortion of less than 1.5% and relative illumination greater than 70%. At all three distances, the lens achieved a distortion rate less than 1% and a relative illumination of 95%, even in the corners. In the image below, the orange dots represent the nominal quality Otoptune wanted to achieve. The red dots represent the minimum production quality. The nominal design is well above the target specifications. However, they were tricky to meet because the required optical quality of the iToBoS is so high.

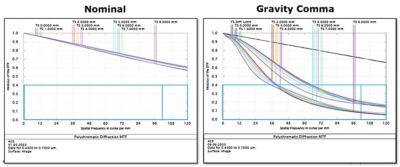

After determining the nominal design, Optotune simulated the real performance of the lenses. Since liquid lenses have liquid inside, Optotune had to account for the effect gravity would have on the lens. When a lens is held vertically, the liquid inside the lens pools at the bottom, creating a so-called coma. In human eye, the coma is small enough not to affect our vision, but optics are so sensitive that coma can affect resulting images. In most cases, this type of error is negligible, but it does matter to doctors trying to determine if a mole or pigmentation is a melanoma.

Optotune simulated the effect of gravity on their lenses in OpticStudio. Below, you can see the nominal design results on the left and the impact of coma on the performance on the right. The results are no longer within the accepted limits indicated by the blue boxes.

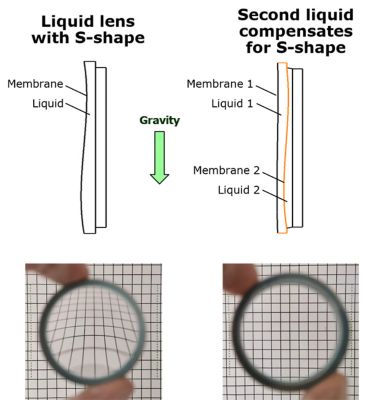

To compensate for the effect of gravity on extremely sensitive optics like the iToBoS, Optotune created gravity-compensated (GC) lenses. These lenses use the same technology as regular liquid lens, but they contain two membranes and two liquids instead of one.

After implementing the GC lens for the iToBoS, Optotune simulated maximum residual coma caused by gravity and maximum allowed astigmatism of the lenses. While the GC lenses compensate for nearly all gravity-caused coma, there will always be some leftover due to manufacturing tolerances. Optotune lenses have incredibly low high-order aberrations, but some magnitude of low-order aberrations like astigmatism will appear. After simulating this worst-case scenario in OpticStudio, the Optotune team determined that the lenses still meet the minimum acceptable parameters for all three distances, as seen below.

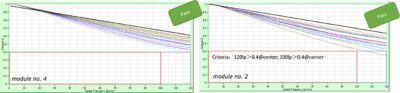

Comparison of Measurement and Simulation

Because the lens performed well in the simulation, Optotune built prototypes of the lens and tested several samples. They chose 420 mm working distance simulation results with residual coma caused by gravity and astigmatism and compared them to two measurement results from the iToBoS. The OpticStudio simulated results and the measurement results from the scanner are comparable and fall within minimum production requirements.

MTF measurements of two samples using Trioptics ImageMaster

Optotune and the iToBoS team are hard at work developing a novel skin scanner to enable an integrative diagnosis platform that detects and diagnoses relevant changes over time in pigmented skin lesions. Optotune lent their optical expertise and world-class optical lenses to make melanoma detection even easier. By simulating the optical performance of the lens in OpticStudio and comparing it to the measured data, it is clear the liquid lenses meet the required spec. The iToBoS team is ready for the next step in the project.

Learn how Ansys Zemax OpticStudio can help with your optical designs.