-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

May 9, 2022

Powering Up Electric Machine Design and Simulation

Hybrid and electric vehicles (HEVs) garner the lion’s share of the electrification headlines, but electric machines are also powering our factories, heating and cooling our homes, and are on the cutting edge of new aircraft technologies. Demand for lightweight, quiet, energy-efficient machines is expected to drive the electric motor market from $106.3 billion in 2020 to $207.3 billion by 2030.1

The automotive sector focus is driven by the need for HEV propulsion technology to meet increasingly stringent miles-per-gallon standards and sustainability initiatives. The aerospace and defense electrification initiatives are not just focused on future fully electric flights, but on replacing existing power transfer technologies in an aircraft, such as the central hydraulic system, with electronically controlled subsystems. Industry 4.0 will continue to rely on electric machines for everything from robotics to conveyor rollers to hermetic compressors.

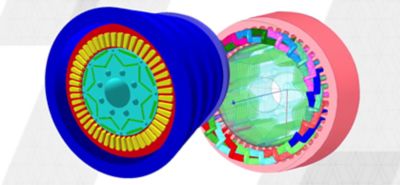

To meet the demand for small, powerful, energy-efficient electric machines that also use rare materials more sustainably, engineers need a comprehensive workflow that stretches from concept design to final manufacturing feasibility. For example, designing a smaller electric motor requires a cooling system design that depends on reliable thermal models; just like quieter motors depend on accurate noise, vibration and harshness (NVH) simulations; and energy efficiency relates to performance output optimization. Electric machines are part of a larger, complex system, so engineers need to account for how electric motors interact with electrical, mechanical, thermal and electromagnetic domains throughout the development process.

“Electric motor design optimization is a complex, multidisciplinary, and often non-linear problem,” wrote Nicolas Riviere, Senior Electric Machine Design Engineer, Motor Design Ltd. in an Ansys blog post. “It involves multi-objective and multi-constraint scenarios where an engineer has to evaluate design tradeoffs necessary due to conflicting performance.”

Creating a Complete Electric Machine Workflow

The acquisition of Motor Design Limited (MDL) will add upfront design capabilities to Ansys’ existing portfolio of multiphysics simulation and analysis offerings for electric machines. MDL’s Motor-CAD software was developed specifically for electric machine design — from its user interface, to its combination of finite element solvers and analytical algorithms, to its motor-specific post-processing capabilities. Motor-CAD contains coupled electromagnetic, thermal, and mechanical modeling capabilities that are designed to enable the rapid design of electric machines across their full operating range.

Two years ago, MDL and Ansys agreed to work together to create a comprehensive design methodology to support electrification applications and satisfy power efficiency requirements. With the acquisition of MDL, Ansys will deliver seamless upfront electric motor design capabilities with even tighter integrations between design modeling and analysis that support the complete electric machine workflow.

For deep analysis and validation of motor designs, Motor-CAD will tap into Ansys Maxwell, our electromagnetic field solver; Ansys Fluent for fluid simulation, Ansys optiSlang process integration and design optimization (PIDO) software, and other Ansys products. Combining these solvers with Motor-CAD delivers high-fidelity, 2D/3D analysis capabilities that enable users to analyze end effects, demagnetization, core loss, hysteresis, NVH, and other advanced electromagnetic phenomena, as well as design complete motor cooling systems.

The addition of Motor-CAD to the Ansys electric machine design flow creates a complete end-to-end workflow for electric machine design, beginning with electromagnetic and thermal design, and progressing through optimization and validation.

“Motor-CAD is the leading electric machine design tool. Bringing its technology into the Ansys family of multiphysics analysis software solutions will allow us to deliver tighter integrations and seamless workflows for all aspects of electric machine design,” said Shane Emswiler, senior vice president of products at Ansys in a recent press release. “Together, we will provide customers with the most comprehensive solution for electric machine design, which is critical as industries and companies around the world pursue more electrification initiatives.”

Increasing demands to push the boundaries of electric machine design and performance require multiphysics design and optimization from an early stage in the design process. Ansys customers will benefit from a class-leading, purpose-built electric machine design tool, robust simulation and analysis, and system validation – all in a complete workflow.

Get a free trial of Ansys Motor-CAD today!

1. “Electric Motor Market Size to Reach USD 207.3 Billion by 2023 at CAGR 6.7%,” Valuates Reports, March 3, 2022