-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

July 12, 2017

In Search of a Better Design with Topology Optimization

When reducing the mass of your models, are you also optimizing for other important design elements such as thermal performance, fabrication constraints or if the casting needs to be water-tight?

Thermal problems are very common in engineering design such as automotive powertrain, electronic cooling system, etc. Topology optimization can also be applied for thermal analysis to improve the cooling performance or for coupled thermal-mechanical analysis to improve the thermal and structural performance simultaneously.

Below is an example of topology optimization for a condenser. Similar to a heat exchanger in a mobile A/C system, the job of a condenser is to extract the heat. Therefore, maximizing the heat conduction is typically the goal of a condenser design. Ignoring this requirement during topology optimization would not produce a good design. With thermal analysis, the temperature distribution and heat fluxes in a model are computed. These temperature responses or Heat Transfer Compliance (HTC) responses can be used in topology optimization as objectives or constraints. By minimizing temperature or HTC, the heat conduction in a model will be maximized.

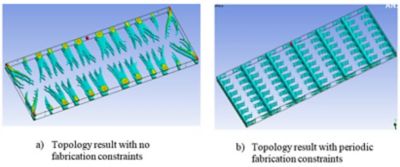

The wireframe shows the boundary of original design space. Figure A shows the topology results of the condenser with minimizing HTC as the objective, but no fabrication constraints to control how this is done. This gives a traditional tree-like structure which is the most efficient shape to dissipate heat, but would be difficult to manufacture. The customer is set up to more easily manufacture a fin-like design, so periodic fabrication constraints can be applied to give the result shown in Figure B.

Topology Optimization with Thermal Analysis

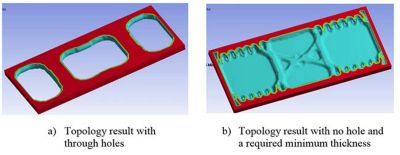

No-hole Option for Topology Optimization with Casting Fabrication Constraints

Another important requirement to take into account is ensuring that the final casting design is water-tight. It is preferred in many applications, such as engine cover design, that there are no through holes in topology optimized parts. Below is a comparison for casting with and without holes. The traditional casting fabrication constraints create through-holes in the structure to reduce weight. While the casting fabrication constraints with no hole option removes material from the top and the bottom while ensuring a specified minimum thickness.

Get more information about how to handle these important design requirements and many other new GENESIS structural optimization features (such as support for Ansys super-elements, RSM, pre-stressed modal etc.).