-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

ANSYS BLOG

April 22, 2024

The Hydrogen Remix: Battolyser Systems Revolutionizes Renewable Energy with a Century-old Invention and Simulation

With inventions that advanced electricity, sound recording, and motion pictures, it’s no surprise that Thomas Edison’s nickel–iron (NiFe) battery is a catalyst for modern-day renewable energy solutions more than a century after its development. Edison patented the battery in 1901, which was a redesign of Waldemar Jungner’s NiFe battery from a few years earlier. The intended use was for early electric vehicles, though he worried about the battery’s safety. It produced an unwanted output of hydrogen. Nevertheless, the batteries were in production for more than 70 years — first by the Edison Storage Battery Company and then Exide, which bought the company in 1972 and produced them until 1975 — finding a place in mining, military, and railroad applications. Some railway vehicles still use versions of the NiFe battery today, manufactured by other companies.

However, more than 100 years after its invention, a Dutch professor discovered new potential for the NiFe battery. Fokko Mulder, a professor at Delft University of Technology in the Netherlands, recognized the battery’s hydrogen output as an advantage for renewable energy development. Using Edison’s battery as inspiration, Mulder and his research group invented the world’s first integrated battery and electrolyzer: the Battolyser®, which has a unique, dual purpose for electricity storage and hydrogen production. Operating as both a battery and an electrolyzer, it efficiently stores electricity and splits water into hydrogen and oxygen when charged.

Thomas Edison, circa 1919

With its flexibility, the technology unlocks new ways to significantly reduce your levelized cost of hydrogen (LCOH). Essentially, it facilitates hydrogen production when renewable power is available and inexpensive, automatically switches off when it’s not, and then powers back on when it is. Due to this intuitive capability, the Battolyser® can produce 100% green hydrogen. In addition, its integrated battery functionality unlocks revenues from trading electricity and lowers investments in off-grid renewable projects resulting in the lowest LCOH.

With access to Ansys simulation through the Ansys Startup Program, Battolyser Systems can make iterative design changes virtually, eliminating the need for costly physical prototypes and testing. By integrating Ansys simulation to fluids and structures applications, the eco-conscious startup cuts costs, optimizes design, and ensures product reliability while continuing its mission to advance sustainable, green hydrogen solutions. After all, Edison famously said, “When you have exhausted all possibilities, remember this: you haven’t.”

Thomas Edison’s nickel–iron (NiFe) batteries under the Exide brand at the Thomas Edison National Historical Park in New Jersey. Image being used under the Creative Commons Attribution-Share Alike 3.0 Unported license (User:z22, CC BY-SA 3.0) via Wikimedia Commons.

Inspired by Edison’s NiFe batteries, the Battolyser® operates as both a battery and electrolyzer. Battolyser® 250A model pictured.

Simulating Sustainable Energy Solutions

The Battolyser® achieves efficiency levels consistent with current electrolysis technologies, boasting up to 80% efficiency even at minimal capacity. So, how does it work? When renewable electricity is available and prices are low, it charges like a normal battery. Once fully charged, it becomes an electrolyzer and automatically produces hydrogen, which can be stored or used. Resourcefully, when renewable production stops and prices are high, the Battolyser® can stop producing hydrogen and sell its stored electricity to the grid.

In this way, the technology increases the economic viability of renewable energy solutions by storing excess power when prices and demands are low, producing hydrogen when prices are more favorable, and selling stored electricity to the grid when prices are high.

Battolyser Systems says Battolyser® is intrinsically safe in any operational mode, even at low and rapidly changing loads. The system provides continuous operation with the ability to switch between electricity storage and hydrogen production. Its automatic operation is one of its most innovative features and its patented NiFe technology is inherently robust with industry-leading efficiency and durability, according to the company.

The Ansys Startup Program encourages eligible early- to mid-stage startups by offering affordable access to Ansys’ multiphysics simulation solutions. After being introduced to the program by Infinite Simulation Systems, an Ansys Elite Channel Partner, Battolyser Systems implemented Ansys solutions to aid product development.

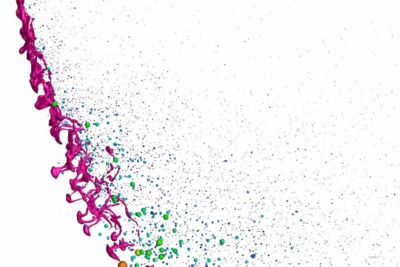

Ansys Fluent supports multiphase flow modeling with capabilities for gas–liquid, liquid–liquid, gas–solid, and particle flows, including the discrete element method (DEM).

“Joining the Ansys Startup Program offers Battolyser Systems numerous benefits,” says Saeid Khalafvand, multiphysics group manager at Battolyser Systems. “Startups often struggle with budget constraints. Ansys provides favorable rates to access the Ansys software, making powerful simulation tools affordable Ansys software offers advanced capabilities like structural analysis, fluid dynamics, and electrochemistry simulation, aiding Battolyser Systems in optimizing designs and ensuring reliability before manufacturing.”

Khalafvand and his team use Ansys Fluent computational fluid dynamics (CFD) software to model and analyze multiphase flow, including volume of fluid (VOF), the behavior of hydrogen bubbles in electrolytes, and electric current distribution and mass transfer in multiphase mediums. They also use Fluent for post-processing.

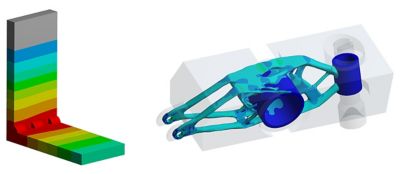

On the structural side, they incorporate Ansys Mechanical finite element analysis (FEA) simulation to model assembly processes, layout test setups, and field load cases such as pressure, temperature, and vibration. In addition, they leverage the implicit and explicit solver to optimize geometry adaption; material parameter fitting; material usage for metal and polymers; and to assess deflection, deformation, and stress. The extraction of results is applied to post-processing, which supports damage models, safety, and performance.

Ansys Mechanical offers thermal analysis, a range of materials models, and structural optimization, including parametric, shape or mesh morphing, and topology.

Designing Sustainably Sourced and Scalable Products

Battolyser Systems says eco-conscious design, development, and scalability of the Battolyser® sets it apart from the competition.

“Simulation software enables Battolyser Systems to iterate quickly through design variations without physical prototypes, speeding up product development,” says Khalafvand. “It also allows validation against performance requirements and optimization for efficiency and durability, ensuring products meet customer expectations.”

Virtual prototyping not only accelerates development, but also minimizes material usage — another benefit for the sustainability-focused startup. In fact, Battolyser Systems says it designs the Battolyser® using only recyclable materials like low-grade nickel and iron, aligning with the European Union’s Renewable Energy Directive and anticipated restrictions related to the Inflation Reduction Act in the United States. As a result, the company says Battolyser® is a sustainable and scalable solution to produce green hydrogen at a lower cost, balance the grid, and store renewable energy.

Battolyser® 500

Battolyser® 1000

Battolyser Systems offers three models: the Battolyser® 250A, which is currently available, and the Battolyser® 500 and Battolyser® 1000, which will be available in 2025 and 2026, respectively. The Battolyser® 250A is a 1 megawatt (MW)/megawatt hour (MWh) system, while the Battolyser® 500 can handle capacities between 2-5 MW/MWh. The Battolyser® 1000 is designed for large-scale operations with capacities up to 500 MW/MWh. For reference, just 1 MW is equal to 1,000 kilowatts (KW) or 1 million watts (W).

Battolyser Systems has a factory in Schiedam and will break ground on its first large-scale production facility in the port of Rotterdam in 2027.

Envisioning a Cleaner World, Naturally

The Dutch startup is dedicated to advancing renewable energy solutions globally.

“We envision a world in which most energy comes from renewable sources such as solar and wind,” says Khalafvand. “To realize an affordable energy transition with a secure energy supply, we need to minimize short-term energy losses and achieve the lowest long-term energy costs.”

Ahead of his time, Edison echoed a similar sentiment. “I’d put my money on the sun and solar energy,” he reportedly said. “What a source of power! I hope we don’t have to wait until oil and coal run out before we tackle that. I wish I had more years left.”

Fortunately, today’s innovators are continuing to invest, both figuratively and literally, in renewable energy solutions. To support the worldwide energy transition, Battolyser Systems uses technologies like Ansys simulation to speed up product development, advance technology, and cut costs closer to home.

“Participating in the Ansys Startup Program or similar initiatives is highly advantageous for startups like Battolyser Systems, providing access to vital simulation tools that assist us greatly,” Khalafvand adds.

To explore what Ansys can do for your early- to mid-stage business, visit Ansys Startup Program.