-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

Boost efficiency and reliability with performance design and component optimization.

Electrical machines are powering our modern world from smart pumps and electric vehicle (EV) propulsion to humanoid robots and moving us closer to a more sustainable future.

Motor and generator design varies significantly. For example, smaller motors such as nanomotors and micromotors require only a few moving parts while industrial motors such as hydroelectric power generators, heating, ventilation, and air conditioning (HVAC) units, and EV transmissions are often larger and involve complex assembly.

Mordor Intelligence reports that the global industrial motors market is estimated at $22.31 billion in 2025 and is projected to reach $28.21 billion by 2030. Precedence Research shows a similar growth expectancy for the global industrial generator market, which is estimated at $22.53 billion in 2025 and projected to reach approximately $38.22 billion by 2034.

With such vast scope and application, coupled with growing demand, motor and generator manufacturers strive to achieve low-cost, lightweight, energy-efficient targets without sacrificing safety or product quality. Common design challenges include quick design specifications, high material costs, and the complexities involved in understanding the behavior of advanced magnetics, thermal management, and noise, vibration, and harshness (NVH). As a result, motor and generator design requires efficient engineering in a variety of disciplines, from electronics and material science to mechanics and fluids.

With diverse physics-based insights and an inherently efficient nature, digital engineering offers a comprehensive solution to overcome these challenges and inform design with actionable, physics-based insights while cutting costs through virtual testing and prototyping. By integrating technologies like multiphysics simulation, digital twins, and artificial intelligence and machine learning (AI/ML), motor and generator manufacturers can boost efficiency and reliability with improved performance design and component optimization.

Meet Complexity With Efficiency

With distinctive purposes and nuances, each type of motor and generator involves a unique design. For example, in permanent magnet motor design, engineers must often meet requirements around torque and speed, which involves specific design components like a set number of magnetic poles. Engineers must also consider factors like NVH, thermal management, material selection, cost, and efficiency.

Precision is critical in motor and generator design, with most manufacturers striving to exceed 90-95% efficiency. This means competition is stiff, and even 4-5% efficiency gains create a significant impact and market advantage.

Although they leverage digital engineering differently, both performance design and component optimization help engineers increase efficiency and reliability while improving costs and material selection. For example, simulation analyses, including advanced magnetics and thermal behavior, provide an opportunity to enhance motor robustness, increase efficiency, and minimize demagnetization.

There are two main design phases in manufacturing. The first phase is often called the request for quotation (RFQ) or quick-design phase. In this phase, a manufacturer typically has as little as two to four weeks to turn around a product estimate and potential design. In this instance, an engineer might consider performance design, which looks at a product as a whole and focuses on improving its operational efficiency and functionality.

After the RFQ phase, engineers move to the second phase, which is called detailed design. During this phase, engineers can focus more on component optimization, which examines every part of a product, optimizing the design and development of individual components to improve performance and efficiency.

Industrial motors power industrial equipment such as pumps, compressors, fans, conveyor belts, generators, and air-moving systems.

Stepper motors are commonly used in robots and other industrial automated applications.

Put Simulation To Work for You

With critical insights from multiphysics simulation, Ansys solutions increase trust in digital engineering practices. Manufacturers can inform performance design and component optimization to improve the behavior, durability, and reliability of industrial motors, generators, and their components. In addition, virtual testing and prototyping minimize the time, cost, and material waste related to traditional physical methods.

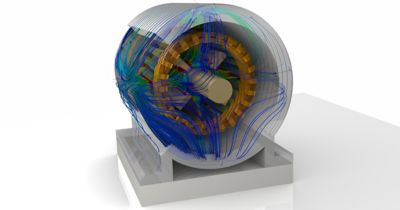

WEG, an Ansys customer and global leader in electrical technologies and automation, used Ansys simulation solutions to develop a revolutionary industrial motor with support and additional services provided by ESSS, an Ansys Apex Channel Partner.

“With Ansys’ powerful simulation tools and ESSS’ excellent support, we have conducted extensive multiphysics validations in a virtual environment, leading to the successful development of advanced products like the W80 AXgen,” Cassiano Antunes Cezario, R&D manager at WEG, said in a press release. “Ansys simulation provides the ideal balance between speed and reliability — giving us confidence that our products will be durable and perform to our customers’ expectations. We are committed to efficiency, which makes using Ansys simulation an easy yet crucial choice.”

Ansys supports industrial motor and generator design with multiphysics simulation solutions for everything from mechanics and fluids to electromagnetics and materials science. For example, the Ansys Electronics Desktop electronics systems design platform offers a wide range of electronics simulation.

Tools like Ansys Maxwell advanced electromagnetic field solver and Ansys Motor-CAD dedicated electric motor design tool for multiphysics simulation are particularly helpful when engineers are pressed on time during early design phases like RFQ. Maxwell software delivers faster transient analyses with reduced data footprint for faster solution time, while Motor-CAD software is equipped with modeling templates for fast multiphysics simulation across the full torque-speed operating range.

Outside of electronics simulation, select structures and fluids simulation tools include Ansys Mechanical structural finite element analysis software and Ansys Fluent fluid simulation software.

In addition, the Ansys Granta materials information, selection, and data management product collection supports sustainability and compliance with environmental standards.

Ansys Motor-CAD software is dedicated to motor design and offers modeling templates for fast multiphysics simulation across the full torque-speed operating range.

Reap Rewards Beyond Multiphysics

Expanding upon multiphysics, Ansys TwinAI AI-powered digital twin software and the Ansys Twin Builder simulation-based digital twin platform integrate the accuracy of physics models with insights from real-world data powered by AI/ML techniques. This combination powers Ansys hybrid digital twins, which enable real-time monitoring, predictive maintenance, and performance optimization across operating scenarios and product variations, automatically adapting to changing conditions. For motor and generator design, digital twins support virtual prototyping, which drastically reduces the time, money, and materials required for repeated physical prototyping. Virtual prototyping also enables optimization in a virtual space and helps ensure that products are represented accurately.

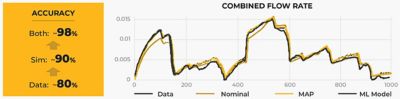

An Ansys study found that a joint approach of data and physics produces around 98% accuracy compared to data-driven or simulation-based models, which individually garner approximately 80% and 90%, respectively. Due to their high accuracy, Ansys digital twins build stronger confidence in virtual testing.

The chart depicts the accuracy flow rate of combining data-driven and simulation-based modeling.

Design for the Future — Today

By leveraging technologies like multiphysics simulation, digital twins, and AI/ML, motor and generator manufacturers improve performance design and component optimization, while increasing efficiency and reliability.

Ansys is dedicated to supporting industrial motor and generator design with innovative solutions for industrial processes and equipment. To learn more, check out one of the following on-demand webinars:

Power Tools – How to Model a BLDC Electric Motor

Heavy Traction Systems – How to Model an Alternator

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.