-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

TOPIC DETAILS

What is Fluid-Structure Interaction?

Fluid-structure interaction (FSI) describes any phenomenon where a flowing fluid interacts with a movable or deformable solid structure. Forces from the fluid flow, in the form of pressure or shear force, can cause the solid object to change its shape or undergo rigid body motion. In turn, changes in the shape or motion of a solid object can alter the fluid flow field. FSI is a type of multiphysics interaction involving fluid dynamics and solid mechanics.

Engineers use simulation tools and testing to study fluid-solid interaction and to understand the real-world interactions of their products as fluids flow around or through them. Those interactions can affect the performance of the products they are designing or maintaining, as well as their robustness if the deformations become too large or occur too frequently. Wind noise of a passing car, the up-and-down motion of a commercial aircraft's wings during flight, or how the heart pumps blood are all examples of FSI in the real world. In severe cases, FSI can result in structural failure, injury, or death. The Tacoma Narrows Bridge collapse in 1940 due to aeroelastic flutter and the Ferrybridge Power Station cooling towers collapse in 1965 due to wind turbulence are two well-known examples. A more common form of FSI that can lead to failure is water hammer – a loud banging caused by sudden water pressure in pipes.

Engineers couple computational fluid dynamics (CFD) and finite element analysis (FEA) software tools to create FSI models that predict the behavior of both domains when loads transfer across the fluid-solid interface or changes in the shape or location of the fluid-solid interface occur. The use of FSI analysis is increasing due to improvements in coupling algorithms and enhancements in computing performance.

Different Types of Fluid-Structure Interaction

The type of FSI a system experiences depends on the type of structural deformation the solid object undergoes and how strongly each physics affects the other physics in the system.

One-Way vs. Two-Way Coupling in Fluid-Structure Interaction

FSI studies involve the transfer of forces from a fluid to a solid, as well as changes in the physical characteristics of the two domains resulting from their interaction. Engineers break the coupling into the following two categories.

- One-Way FSI Coupling

The most common type of one-way FSI coupling, also referred to as weak coupling, is when a system transfers forces from the fluid flow to the solid, but the solid’s response has a negligible impact on the behavior of the fluid flow. This is usually because the distance in which the solid deforms is small relative to the volume of fluid causing the deformation. The wing on a race car is a good example of one-way FSI coupling. The flow of the air over the wing creates downforce on the wing, but the wing is rigid enough for those forces not to change the shape of the wing.

One-way FSI can also occur when the motion of an object imparts or extracts momentum from a fluid, changing the velocity and pressure of the fluid domain without creating noticeable changes to the object's shape or motion through the surrounding fluid. A good example of this is an electric fan. The motion of the fan blades increases the velocity of the air flowing through the fan without significantly changing the blades’ shape.

A one-way FSI simulation applies the pressure and shear forces from a solved CFD simulation to the fluid-solid interface of an FEA structural model, then solves for stress and strain in the structural domain, or the velocity of the solid at the fluid-solid interface is used as a boundary condition for the CFD model. In both cases, the force or velocity only travels from one domain to another.

- Two-Way FSI Coupling

The most common form of two-way FSI coupling, often referred to as strong coupling, occurs when the fluid-domain forces on the solid object cause the solid to distort enough to change the pressure or velocity of the fluid. Those changes then alter the fluid forces, which modify the deflection and motion, and, in turn, change the flow.

A two-way FSI simulation uses algorithms to transfer the solid object's deflection back to the CFD model. Sometimes, when those changes are significant enough, the mesh of the fluid ranges becomes distorted and no longer valid. The software will use an automated process called remeshing to redo the mesh. In the most extreme cases, the fluid domain's topology changes as passages open or close.

Two-way simulations can use two different methodologies for iterations between the solutions in the CFD and FEA solvers as the model steps through time. In the explicit or sequential approach, loads and deflections are transferred only once per time step. The implicit or simultaneous approach solves both the fluid and the structural simulations simultaneously, exchanges loads and deflections, and then solves again at the same timestep until the solution converges. The system then moves to the next time step.

The explicit method is more straightforward to set up and uses fewer computer resources because there is only one solve per iteration. However, it is less stable than the implicit method, and the models may diverge. Most engineers choose the implicit workflow when modeling strongly coupled systems and desiring greater accuracy than the explicit method provides.

Structural Deformation Types

Another way engineers categorize fluid-structure interaction problems is to identify the type of distortion the structural domain undergoes. Users of simulation tools use this information to determine the proper modeling approaches and which algorithms to use for data exchange between CFD and FEA solvers.

The most common types of deformation are:

- Small Deformation

Models with small structural domain displacements use one-way simulation. This approach solves the CFD model first and then applies the forces to the structural model. This situation does not require a change to the shape of the fluid-structure interface.

Sometimes, oscillations in the fluid flow exert small, cyclical forces on a flexible surface of the structural part of the system, and the solid part responds by vibrating. This vibration then generates sound waves that travel through the fluid without changing the overall flow characteristics. Aerodynamics engineers refer to this type of fluid-structure interaction as acoustic-structure interaction (ASI).

In hydrodynamics, a pressure wave can resonate in a pipe or duct, causing vibrations in the solid components. This oscillation is called water hammer. Both ASI and water hammer generate noise and can sometimes fatigue structural components.

- Large Deformation

When the deflection or motion of the solid domain is large enough to change the fluid flow, two-way FSI is required. In addition, engineers may need to set up their simulation to use methodologies to distort the CFD and FEA meshes or even remesh geometry in both domains. The velocity of the distortion or motion also drives the time step size for each solver iteration.

- Large Oscillating Deformation

When the changes in fluid forces excite a natural frequency in the structure, the system can experience large oscillations. Those oscillations can grow further as the fluid flow adds more energy to the system. Aerodynamicists call this type of coupling aeroelasticity.

The Tacoma Narrows Bridge failure is an example of aerodynamic loads exciting vibration in a structure to the point where the structure failed.

- Rigid Body Motion

Complex two-way fluid-structure interaction can also occur with structural components that don’t distort, but that have momentum. This rigid-body motion still requires two-way coupling and remeshing of the fluid domain.

- Body Load Induced Deformation

Body loads from gravity or electromagnetic fields, along with thermal strains, can distort the solid domain that affects an FSI system. Actuators and drive shafts also place loads on the structural domain. In biological systems, the relaxation and contraction of muscles move fluids in the body. Engineers should make sure they understand and account for any body loads in their FSI models.

Other Physics with Fluid-Structure Interaction

When a simulation includes other loads in the fluid or structural domain, the FSI system becomes a more complex multiphysics simulation. A common example of this is fluidic Micro-Electro-Mechanical Systems (MEMS) devices. They perform by coupling electrical, electrostatic, magnetic, thermal, fluid, and structural physics into one device.

The most common physics added by engineers to FSI studies is conjugate heat transfer. This type of simulation uses CFD-calculated temperatures and velocities to determine the heat flux between the solid and fluid domains.

Applications for FSI Across Industries

Fluid-structure interaction occurs in many systems across multiple industries, but a few stand out because fluid flow is integral to their products. The following is a list of the industries where FSI plays a strong role in increasing robustness and optimization performance.

Aerospace

If you have ever looked out of the window of a passenger jet and watched the moving structure of a wing, you have watched two-way FSI coupling with large deformation. The aerospace industry produces many devices that travel through the atmosphere, making FSI an essential aspect of their design and maintenance. The interaction between the fluid and solid domains becomes even more critical when aerospace vehicles travel faster than the speed of sound and shockwaves form, creating significant forces.

Some common examples of fluid-structure interaction in aerospace that engineers care about are:

- Aeroelasticity of wings

- Rigid body motion of objects like spare fuel tanks and weapons falling away from the aircraft

- Ballistic trajectories of items through the air

- Loads on control surfaces

- Inflation of parachutes and parafoils

- Sloshing of fuel in tanks

- Acoustic and aerodynamic loads on rocket nozzles

Automotive

Cars also travel through the atmosphere, and they move liquids and gases through their drive and climate-control systems. If you have ever driven a car with a sunroof, you have experienced fluid-structure interaction when you heard a buffeting sound at certain speeds. Most FSI in the automotive industry is one-way, because the automotive structures are usually rigid.

Biomedical

The human body is a complex fluid-structure system in which many structural components are flexible. Both heart chambers and heart valves are great examples of fluid-solid interaction in natural systems. The heart muscles contract and expand to change the volume of the heart chamber, increasing blood pressure and forcing the blood through the heart valves. Heart valves have flexible leaflets that open and close to allow or block blood flow. They open when the pressure inside the heart chamber rises and close when the pressure drops.

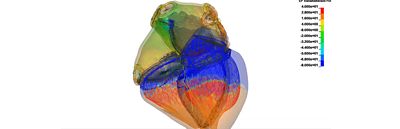

An example of a biomedical FSI simulation of a human heart using the PyAnsys-Heart tool

Civil Structures

Buildings, bridges, and other civil structures interact with wind and water, exhibiting fluid-structure interactions. Very tall buildings not only sway in strong winds but also experience two-way FSI because they alter the wind pattern as they move.

Clean Tech

Two of the most common examples of FSI in clean tech products are the behavior of solar panels and wind turbines. Solar panels can be one-way FSI coupling when the panels don’t move and are rigid, or two-way when the panels can flex or use actuators for positioning. Wind turbine blades are flexible, bend due to gravity and wind loads, and rotate to change their orientation to the wind.

Turbomachinary

The air or steam traveling through turbomachinery interacts with both the static and rotating solid components inside the devices. Engineers use FSI simulation to evaluate aeroelasticity, forced vibration, valves, and seals. FSI studies in turbomachinery are complex because the velocities, temperatures, and pressures are high.

Fluid Systems

Many products have systems that control the flow of liquids and gases through the device or machine. Most valves, seals, sensors, and pumps used in fluid systems experience at least one-way fluid-solid interaction and may use two-way FSI coupling to perform their intended tasks.

Common Challenges and Recommendations for FSI Simulation

Simulating fluid-structure interaction is difficult because it involves modeling two distinct physics that users must set up and run optimally, and because handling their coupling can be complicated. Here is a list of the most common challenges with some recommendations for overcoming them.

Picking the Right Tool for Each Physics

Picking the right CFD and structural FEA simulation tools is the first challenge when undertaking an FSI simulation. Users need a fluid simulation tool that is easy to use, has the right mix of numerical methods to capture the fluid domain’s behavior, solves efficiently, and supports FSI. For example, users working with turbomachinery often choose Ansys CFX computational fluid dynamics software for its strong capabilities in that industry. Engineers modeling other classes of problems will tend to focus on Ansys Fluent fluid simulation software because of its wide range of turbulence models, robust meshing and remeshing, and advanced CFD capabilities.

On the structural side of things, users need a robust, general-purpose platform like Ansys Mechanical structural finite element analysis software that accurately models both linear and nonlinear solid materials and geometry, and offers sophisticated loading as well as the broadest range of capabilities in the industry. Users should work with a tool that includes an easy-to-use and programmable user interface, supporting both one-way and two-way FSI modeling.

A good example of a comprehensive tool for connecting independent physics is Ansys System Coupling physics solver connection software. It delivers one-way and two-way coupling, scripting, data mapping, and data exchange capabilities. Fluid-solid interaction makes it a leading tool for engineers simulating this particular type of systems coupling.

Having Domain Expertise for Fluids and Structures

Fluid and structural simulation are very different, as are the tools for CFD and structural simulation. Some engineers have a deep understanding of both domains, but usually they have a strength in one and a passing acquaintance with the other. One way to help with this is to pick both tools from the same provider, such as Ansys, which also offers comprehensive training classes and webinars to help users get up to speed on both physics. In addition, if the toolset provides scripting capabilities like the PyAnsys pythonic access tool for Ansys software, an expert can set up automation for both physics.

However, the best way to find domain expertise is to work as a team with an expert in the domain you don’t know as well. Then use simulation data management tools, such as Ansys Minerva simulation process and data management software, to collaborate and track models and runs.

Deciding Between One-Way and Two-Way Coupling

Sometimes, it is not clear whether a particular fluid-structure interaction problem requires one-way or two-way coupling. When in doubt, the best approach is to start with one-way because it is simpler and more efficient to solve. If the solution reveals the need for two-way coupling, make the change.

Handling Numerical Instability

Some FSI situations are unstable, or models may be constructed with the wrong mesh or settings, leading to nonconvergence. In these situations, it is best to work with tools like the Ansys portfolio, which offer multiple numerical methods for stabilization, along with comprehensive training and support.

Accessing Sufficient Computing Resources

CFD simulations are computationally expensive on their own. When coupled with a structural FEA run, they can use up a significant amount of resources, especially for two-way implicit coupling. To combat this, make sure you choose solvers that support high-performance computing, such as Ansys CFX, Fluent, and Mechanical, that scale well with parallel processing and GPUs. In addition, explore the use of cloud-based HPC resources like Ansys Cloud to deliver the capacity you need, when you need it.

Related Resources

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.