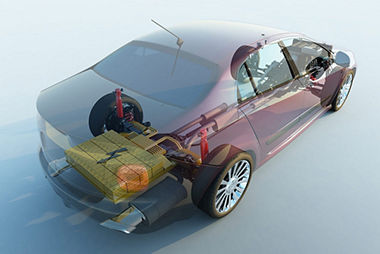

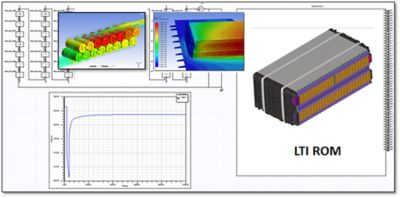

Ansys helps you advance battery designs while balancing safety, performance, size, cost and reliability to make you the market leader. Our multiphysics battery simulation solution helps bring together interdisciplinary expertise at different scales. With our help, you can reduce project costs by up to 30% and design cycle time by up to 50%.

-

-

Access Free Student Software

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

-

Connect with Ansys Now!

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Countries & Regions

Free Trials

Products & Services

Learn

About

Back

Products & Services

Back

Learn

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Back

About

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Free Trials

Performance Modeling Solutions

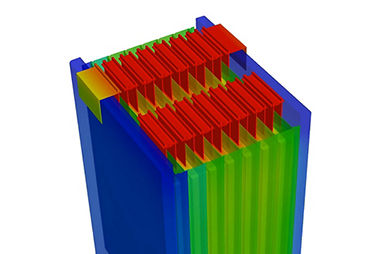

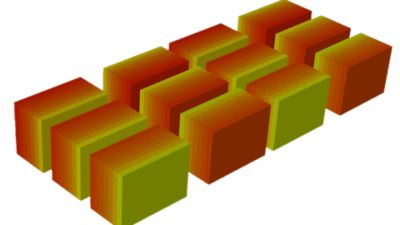

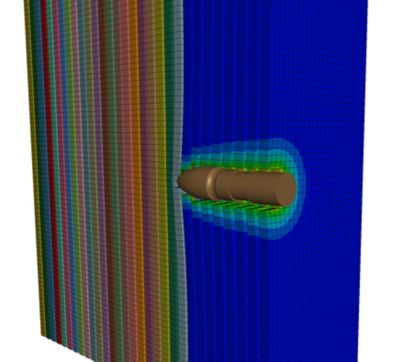

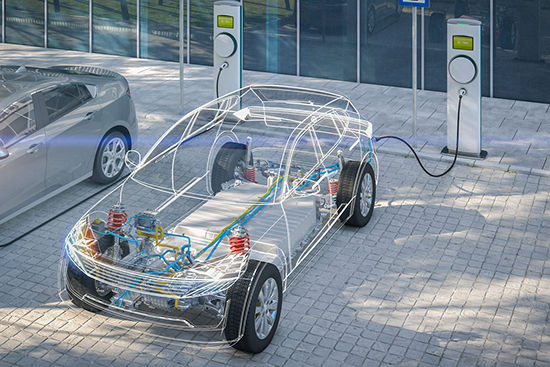

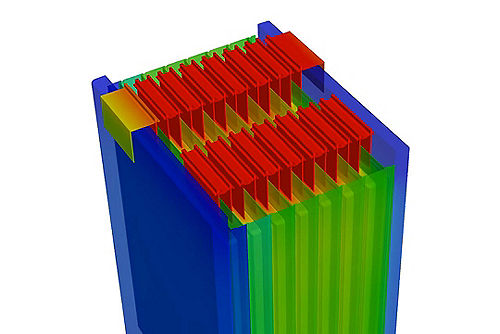

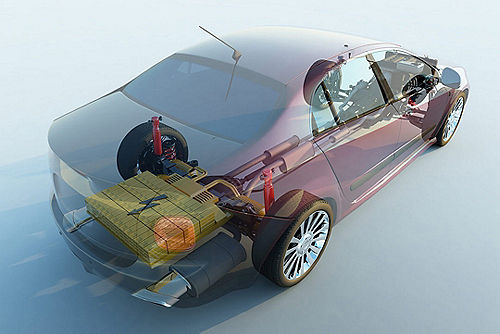

Whether designing a battery for electric transportation or consumer products, every design choice requires complex decisions. Engineers can rapidly evaluate tradeoffs while minimizing reliance on arbitrary design rules and expensive, trial-and-error physical testing. Our accurate battery simulation gets the results you need from electrochemistry to electrode, cell, module, pack and system and the coupling of different physics.

Thermal Management

Battery Applications

Featured Resources

WEBINARS

CASE STUDEIS

WHITE PAPERS & ARTICLES

BLOGS

Let’s Get Started

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.