Ansys Sherlock

Complete Life Predictions for Electronics Components

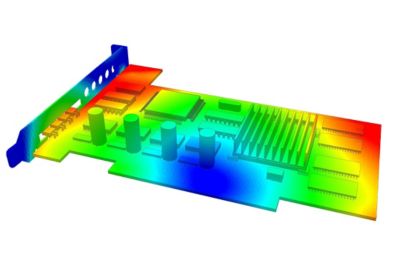

Ansys Sherlock is the only reliability physics-based electronics design tool that provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early stage design.