Automotive

Webinar Series

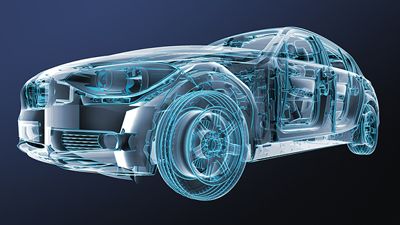

Learn from leading automotive organizations and Ansys experts how engineering simulation drives accelerated innovation.

On-Demand Webinars

How NXP Semiconductors Utilizes Model-Based FuSa Analysis for Automotive SoCs

Speaker: Gulroz Singh, Sr. SoC Functional Safety Architect at NXP Semiconductors

Managing Materials Knowledge at Vitesco Technologies

Speakers: Monica Buzdugan, Team Leader CAE at Vitesco Technologies; Steffen Hartmann, Global Teamlead Simulation at Vitesco Technologies; and Charlie Bream, Principal Product Manager at Ansys

How Webasto Uses Simulation for Automotive Sensor Cleaning

Speaker: Dr. Achim Holzwarth, Team Lead CAE, Webasto Thermo & Comfort SE

How STMicroelectronics leverages simulation to build efficient EV traction inverters

Speaker: Daniela Cavallaro, FEA Modeling and Simulation Manager at STMicroelectronics

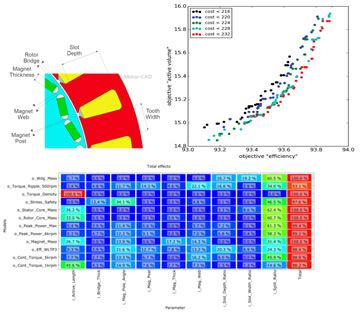

Synergetic Use of optiSLang at ZF-Braking: Review and Future Perspectives

Speaker: Stanley Baksi, Technical Specialist CAE-NVH, ZF-Braking

Driving Lightweighting Excellence Through Materials Digital Transformation

Speakers: Clemens Anzboeck, Materials Engineering R&D, Pankl & Cleon Regensburger, Development Engineer Additive Manufacturing, Pankl

ZF - Solder Joint Digital Twin

Speaker: John Coates - Chief Engineer, Core Technology Engineering, ZF Electronics & ADAS

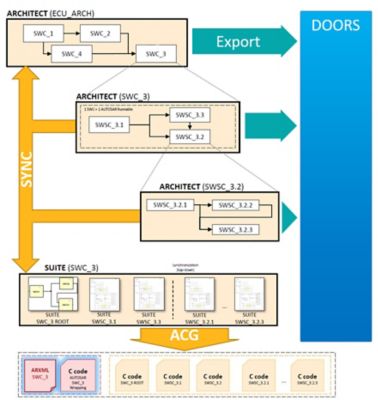

Digital Transformation in Simulation within the Product Development Process

Speaker: Christoph Schulz, Manager Simulation Filter Elements, Mann+Hummel

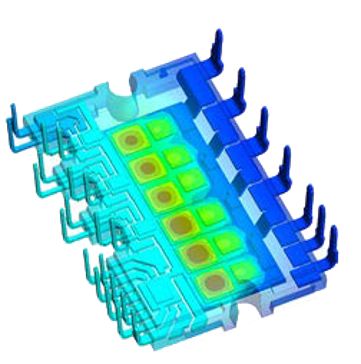

Automate PCB Thermal Simulation Workflow with Ansys Icepak and PyAEDT

Speakers: Michael Schreittmiller, Modules Expert HW, Webasto Roof & Components SE

Porsche Motorsport: Analyzing Power Losses in a High-Performance Powertrain

Speaker: Leonard Mengoni, Development High Voltage Power Units, Porsche Motorsport.

Creating Collaboration and Safety Across Globally Distributed Teams

Speakers: Viacheslav (Slava) Izosimov, Functional Safety Manager, Veoneer &

Daniel Jaikumar, Partner and Customer Success Manager, Intland Software

Daimler on the Journey to Digital Safety Management

Speakers: Rüdiger Diefenbach, Safety Manager, Mercedes-Benz AG & Jan Mauersberger, Lead Product Manager, Ansys

Leveraging Simulation to Realize a Highly Efficient Powertrain

Speaker: Leonard Mengoni, Development high voltage power units, Porsche Motorsport

Lamborghini Shares Best Practices in Materials Data Management

Speakers: Gianpiero Cerrone, Laboratory Composite Engineer presso Automobili Lamborghini S.p.A. & David Campbell, Senior Account Manager, Ansys

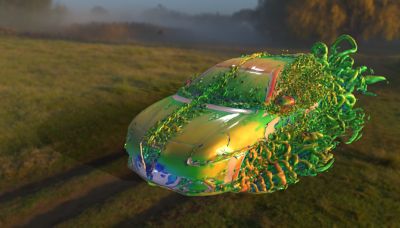

The ID.R - Success Through Simulation — in Only 250 Days

Speaker: Dr. Benjamin Ahrenholz, Head of CAE Department at Volkswagen Motorsport GmbH

Integrating Ansys Sherlock into Continental Automotive’s Design Process

Speaker: Tony A. Asghari - Principal Staff Engineer, Continental Automotive

Ferrari Competizioni GT: Innovating and winning with Ansys Simulation Technologies

Speaker: Ferdinando Cannizzo, Head of GT Racing Car Design and Development, Ferrari Competizioni GT

Discover Industry Best Practices

These industry best practice (IBP) webinars provide insight into how the latest Ansys technology helps you meet your engineering goals: How to build better products faster whilst simultaneously reducing R&D and manufacturing costs.

Recent Webinars

On Demand

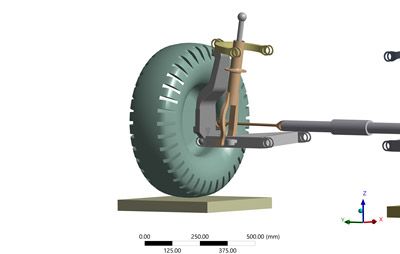

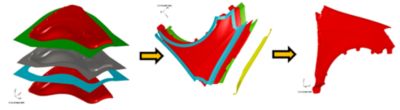

Digital Testing and Validation of Additively Manufactured Vehicle Parts

In this webinar, you'll learn about the holistic digital process chain capabilities to structurally optimize and validate additively manufactured components for the automotive industry.

On Demand

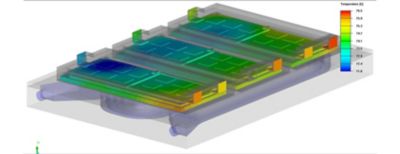

Battery Modeling and Simulation

Battery modeling and simulation are crucial in designing and optimizing battery-powered systems. Battery models are essential tools for system design, characterization, and optimization. They help engineers understand battery behavior under various conditions. Learn how Ansys solutions can support battery modeling and the complete product workflow.

On-Demand Webinar Series

EV Battery Development

In this webinar series, you'll learn how battery cell suppliers and automotive OEMs can use simulation to optimize and accelerate the design, production, and integration of batteries in electric vehicles.

Material Intelligence for Sustainable Automotive Design

In this webinar series, our presenters discuss how the challenges around sustainability, supply chain uncertainty, pivoting to new powertrains all have an impact on how engineers need to accurately evaluate and compare different materials and optimize decision-making during the earliest stages of design.

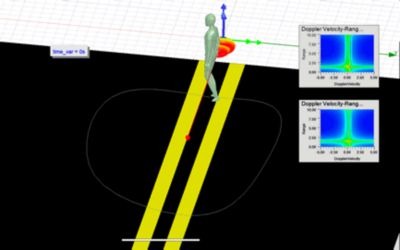

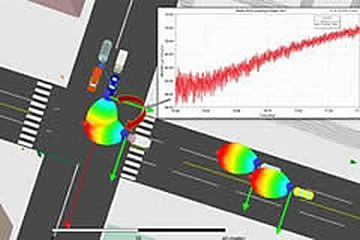

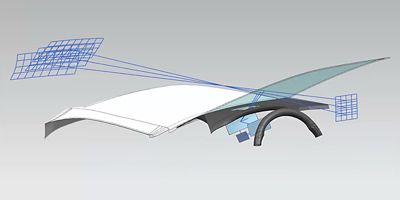

ADAS and Autonomy

Today’s wide range of hands-off driving features share one common trait: They rely on a series of sensors, mounted on the car, to correctly identify a broad spectrum of visual objects and trigger an appropriate response within milliseconds. Radar-based sensors must be rigorously tested and validated before they can be installed. Yet automakers are under extreme pressure to keep costs low and meet aggressive launch deadlines.

The following webinars explain how Ansys simulation solutions are helping automakers address these challenges.

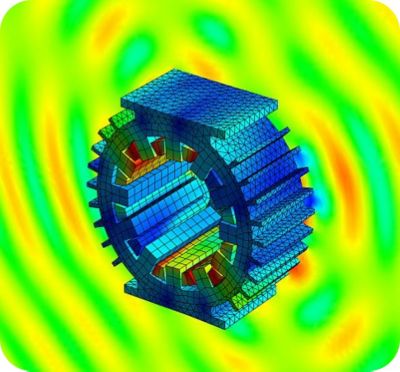

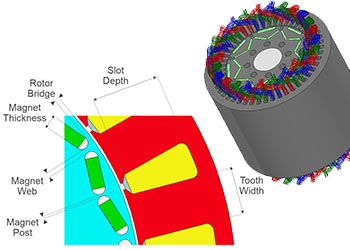

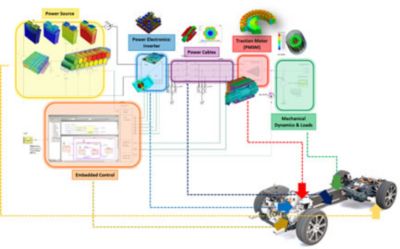

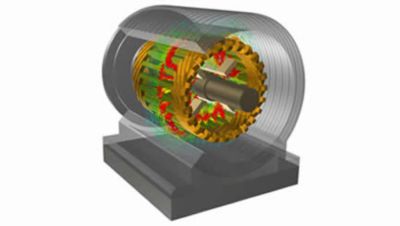

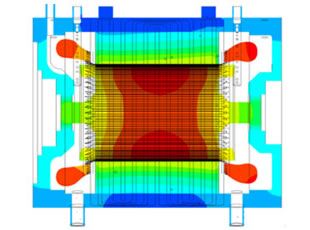

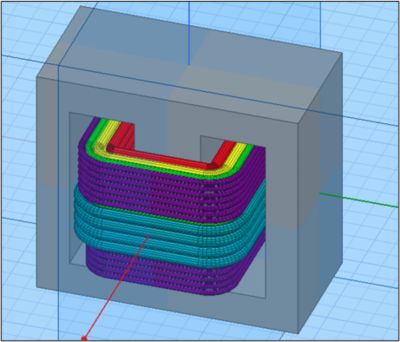

Electric Machine Development Platform

The Electric Machine Development Webinar Series is designed to empower you to achieve performance goals with simulation driven development of electric traction motors, thereby reducing cost and risk of bringing new electrified vehicles to market. Our team of experts will start from a specification of an electric machine for an automotive traction application and throughout this series demonstrate the complete development of an electric machine design using the Ansys platform.

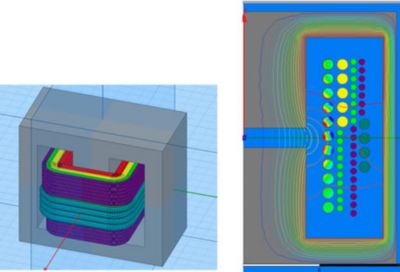

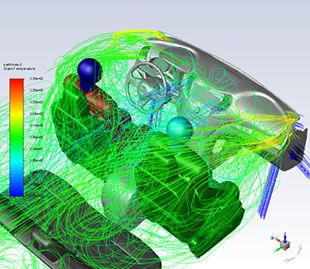

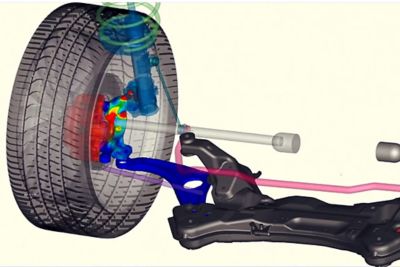

Automotive Electronics Reliability

In this webinar series, our presenters will discuss some of the challenges facing automotive manufacturers. Topics include the necessity for higher-performing components and materials and how to meet more rigorous OEM specifications that meet regulatory standards. You'llalsosee demonstrations of a specialized multi-physics workflow that accounts for all physics impacting automotive electronic systems —from electrical to thermal to mechanical stress.

On-Demand Webinars on Electrification

On-Demand Webinars on Autonomy

Hear From Ansys Experts on Top Technology Trends

In addition to our series of market-leading webinars delivered by distinguished automotive industry experts worldwide, be sure to check out the rest of our automotive webinar offerings. These online, live and on-demand presentations by Ansys experts share technology insights across various key automotive trends.

Recent & Upcoming Webinars

Live Webinar

October 18, 2024

3 PM IST

Accelerate Electric Powertrain Design & Development with Ansys Concept EV

Explore Ansys Concept EV that delivers a revolutionary approach to EV system design to achieve more efficient, longer-range, and lower-cost EVs.

Webinar Series

October 31, 2024

3 PM IST

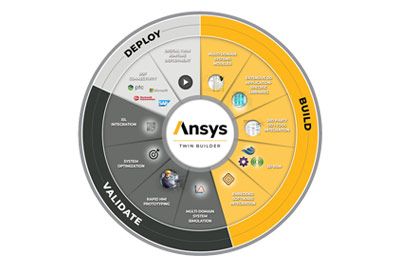

Accelerating EV Development with Ansys Digital Twin

This 3-part webinar series will cover virtual validation workflow for EVs and integration of simulation models in system-level studies through reduced order modeling. Our simulation experts will also share insights on using simulation methods, ROMs, and AI/ML techniques for performance validation through MIL, HIL, and virtual drive tests.

On Demand

Sustainable Electric Motor Design and Development

Join this webinar to learn how to engage your students in electric motor design, which will motivate them to address SDG #13 while expanding their knowledge and understanding of different physics: structures, electric, thermal, and fluids.

On Demand

Optimizing NVH Performance with Ansys' Advanced Solutions

Join us for an in-depth exploration of our advanced NVH (Noise, vibration, and harshness) solutions. This webinar will showcase Ansys's advanced technologies and tools to help engineers tackle complex NVH challenges quickly and precisely.