找出適合您和團隊的電子產品可靠度工作流程

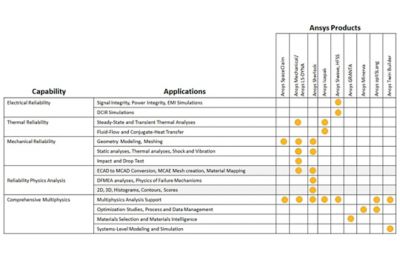

模擬無法一體適用所有。因此,Ansys 提供多種電子產品可靠度工作流程,滿足您的產品需求和可靠度需求。

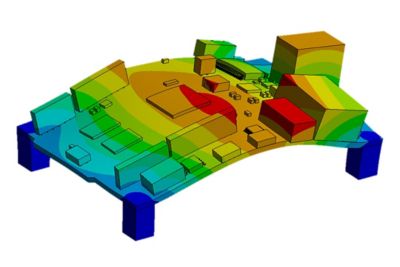

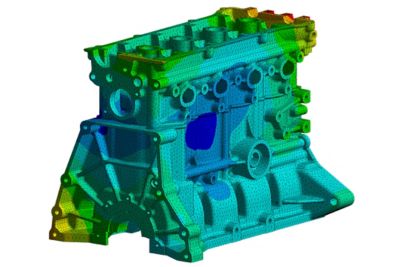

為了執行確保和預測電子產品可靠度的最佳實作範例,需要全方位多重物理量模擬。Ansys 開發各種解決方案與工作流程,以克服現今最嚴峻的模擬與設計挑戰,確保電子產品穩定可靠。

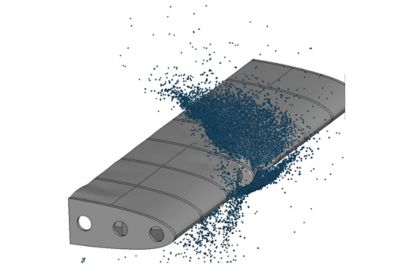

Ansys 電子產品可靠度工作流程可協助您克服眾多電子、散熱和機械可靠度挑戰。這可讓您提升訊號完整性、防止衝擊和振動故障、消除電磁干擾等等。觀賞這支動態影片,瞭解如何運用 Ansys 電子產品可靠度工作流程,在產品上市前確保其能如預期運作。

組織可以使用 Ansys 電子產品可靠度解決方案來擷取各種零件、材料、模擬與其他資料,以及存取可進行模擬的重要材料與元件資料。

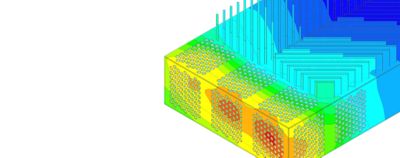

Ansys 電子產品可靠度產品組合的核心,是根據故障物理學 (PoF) 原則進行可靠度預測。電子產品製造商可以使用 Ansys 模擬工具判斷產品需多久時間才會發生故障,並找出發生故障的原因。

工程師可以使用 Ansys 電子產品可靠度工具建立高度自動化的全方位模擬工作流程。

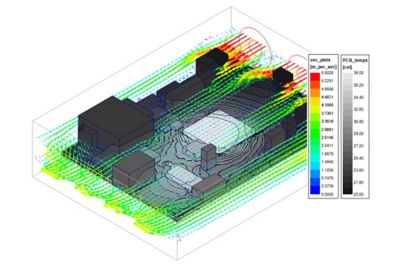

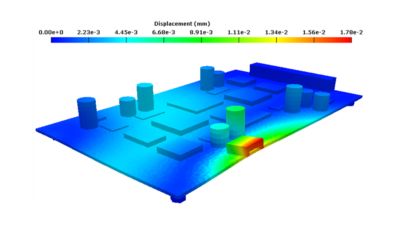

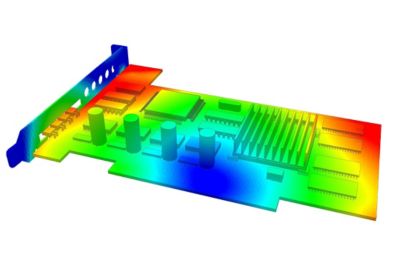

Ansys Sherlock、Icepak、Mechanical、LS-DYNA 等產品之間的整合式工作流程會提供必要的模擬結果,以便將產品設計最佳化並確保現場運作的可靠度。

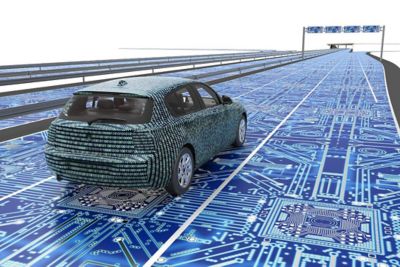

「無論您正在觀察哪一項科技趨勢 (例如 5G、電氣化、AV,以及工業物聯網),PCB 可靠度都是一切需求的骨幹。」

Ansys Icepak 首席應用工程師 Carlos Gomez

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua, sed do eiusmod tempor incididunt ut labore.

以豐富的產業知識為後盾

模擬無法一體適用所有。因此,Ansys 提供多種電子產品可靠度工作流程,滿足您的產品需求和可靠度需求。

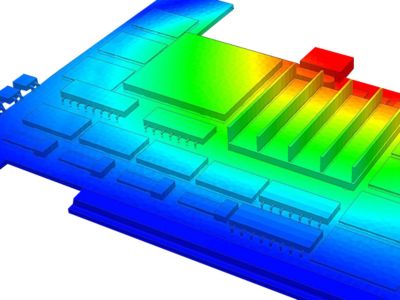

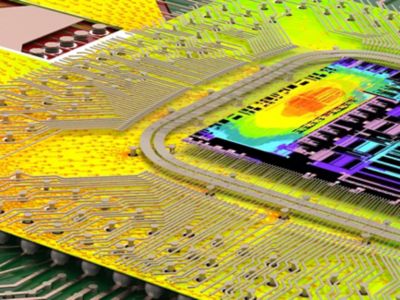

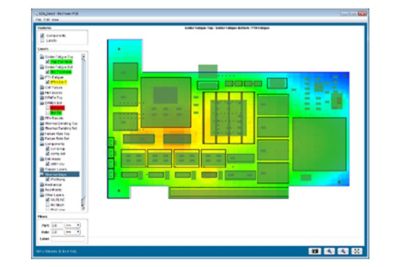

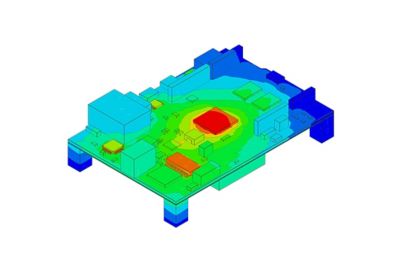

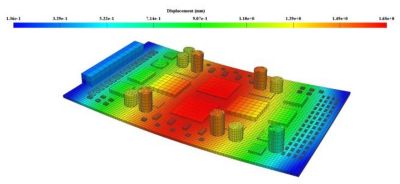

用來判斷 PCB 可靠度的 Ansys 解決方案包含一套多重物理量工作流程,該流程會使用一系列先進的模擬工具。 您可以藉由我們的工作流程解決方案,模擬電子、散熱與機械效應,以判斷產品可靠度。

在構建實體原型前,Continental Automotive 會以幾分鐘的時間測試產品可靠度

Continental Automotive 在建立原型之前,使用 Sherlock 來評估並找出優異的黏合劑材質。 重要發現包括: * 優異的黏合劑材質 – 使用 BGA 黏合後的持續時間比其他黏合劑材質更長。 * 提高客戶提供之現場溫度設定檔的熱循環頻率,會導致 BGA 壽命減半 * 將現場環境設定檔中的 BGA 溫度提高 15°C (因元件功率耗散),能夠縮短故障時間

此網路研討會將示範印刷電路板熱建模的自動化程序。其中將展示 ECAD 資料轉換為 Ansys Icepak 散熱和機械模型的工作流程,然後將結果傳輸到 Ansys Sherlock 以進行焊料疲勞分析。

此網路研討會涵蓋主題包括產品整合,以及與各項工具相關的更新。這些更新能更快、更有效率的進行模擬。另外還有關鍵工作流程的更新,可協助使用者因應重要的電子產品可靠度挑戰。

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。