成果經過實證的高效能軟體

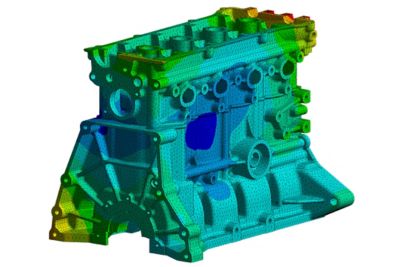

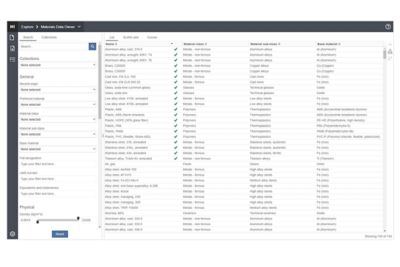

Ansys 模擬軟體已經通過多種產業與應用領域的廣泛驗證。這些模擬工具可提供準確可靠的資料,大幅降低製造成本與測試時間。此外,所有模擬軟體都著重提供精簡直覺的工作流程,讓工程師有更多時間專注於關鍵設計決策。

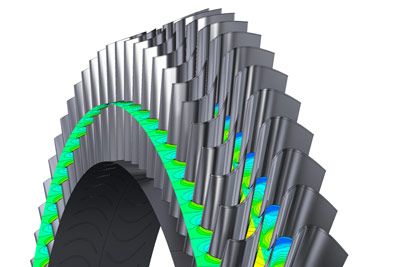

Ansys 提供最先進的軟體,協助設計各式各樣的旋轉式機械設備。無論是開發風扇、泵、壓縮機還是渦輪機,Ansys 模擬軟體都可讓您快速迭代並改進設計。模擬會針對製造與測試前的關鍵指標提出深入洞見。此為相當可靠的方法,可提高效率、降低開發成本,並縮短上市時間。

透過 Ansys 整合式渦輪機械設計平臺,一家旋轉機械公司成功設計出一種離心式壓縮機,該壓縮機能在處理廢水時節省2%至5%的能源。

Ansys 提供全方位模擬軟體集合,非常適合旋轉式機器應用領域。這些解決方案能協助工程師解決各種複雜的問題,例如將渦輪機震動降至最低,或將氫化器的流體流動最佳化。您可以使用這些經過驗證的工具快速將設計最佳化,讓產品更快上市。

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。