結構分析軟體

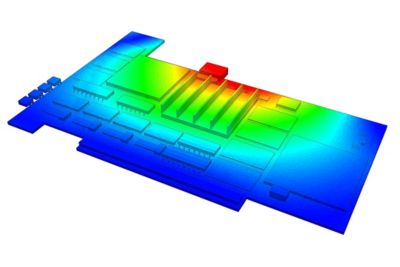

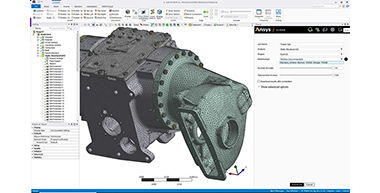

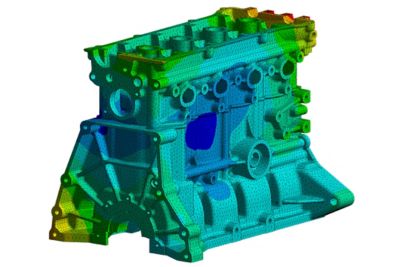

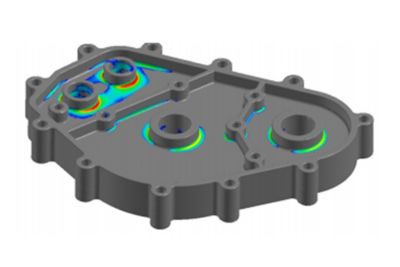

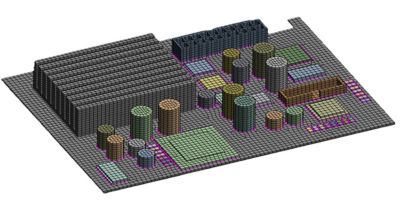

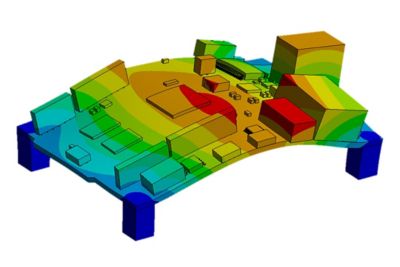

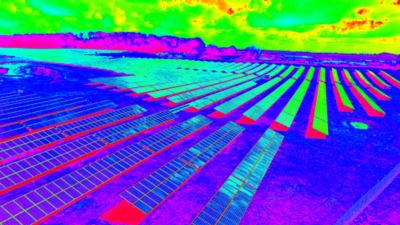

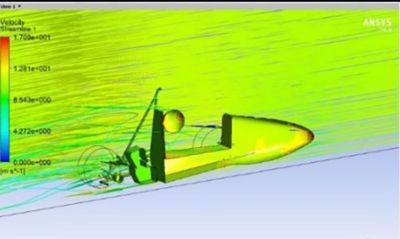

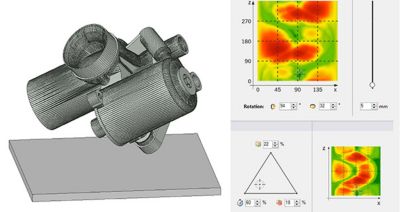

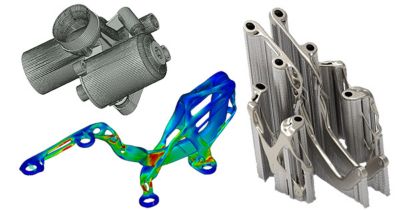

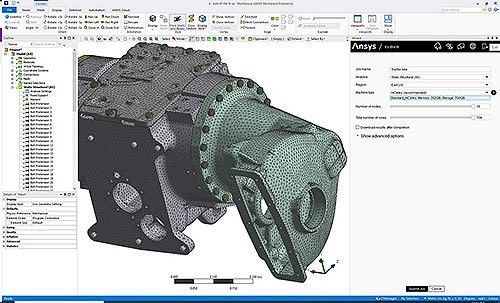

Ansys 提供結構分析軟體解決方案,可讓各個級別和背景的工程師更快速、更有效地解決複雜的結構工程問題。利用我們的工具套組,工程師可執行有限元素分析 (FEA),針對結構力學挑戰自訂和自動化解決方案,並分析多種設計場景。透過在設計週期早期使用我們的軟體,企業可以節省成本,減少設計週期的次數,並更快地將產品推向市場。

Ansys 提供結構分析軟體解決方案,可讓各個級別和背景的工程師更快速、更有效地解決複雜的結構工程問題。利用我們的工具套組,工程師可執行有限元素分析 (FEA),針對結構力學挑戰自訂和自動化解決方案,並分析多種設計場景。透過在設計週期早期使用我們的軟體,企業可以節省成本,減少設計週期的次數,並更快地將產品推向市場。

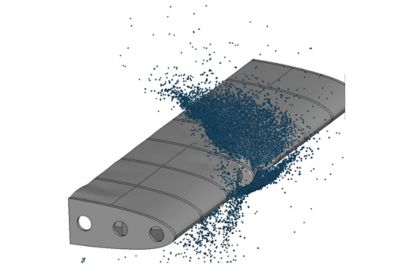

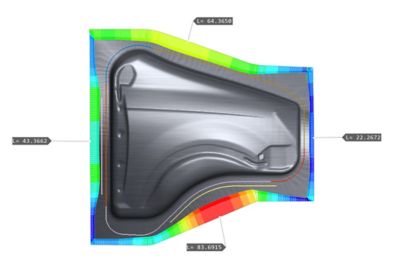

利用我們全方位的結構分析工具套組,工程師可以模擬衝擊、摔落和振動、衝擊和穿透、猛撞和碰撞、乘坐者安全、熱傳遞、焊料疲勞、重複載入等各種狀況。Ansys 結構分析使用一系列應用程式和產品整合,可協助您解決最棘手的產品開發問題。

Within Ansys Mechanical, Ansys Fluent, Ansys Electronics Desktop, and Ansys LS-Dyna, you can easily access HPC in the cloud directly — without the need for any additional setup. Access the hardware and software you need, when you need it, and pay only for what you use.

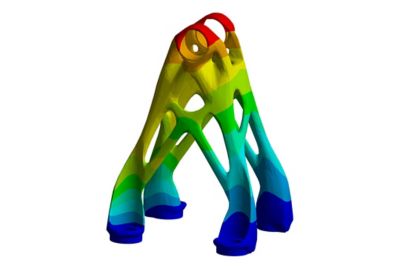

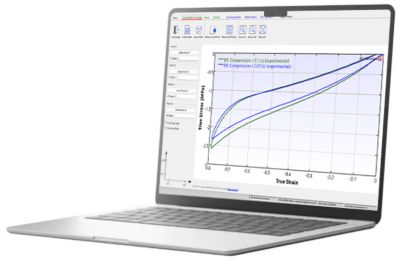

Ansys optiSLang is a process integration and design optimization solution that automates key aspects of the robust design optimization process. optiSLang connects multiple CAx tools and different physics into a holistic, multi-disciplinary approach to optimization.

2025 年 7 月

Ansys Structures 的 2025 R2 版本提供了一套新功能,為我們的客戶提供整體優勢。

Ansys Mechanical

Ansys LS-DYNA

Ansys Forming

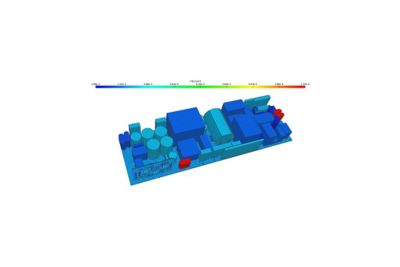

Ansys Sherlock

Ansys Sound

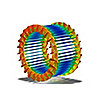

Ansys Motion

輕鬆處理您可能面臨的各種設計環境的複雜性。分析工具的範圍可讓您的產品符合效能目標,並隨著時間推移仍能維持不變的效能。

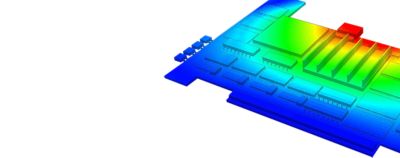

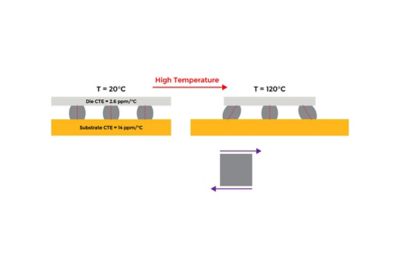

在本次網路研討會中,瞭解如何將 Ansys SIwave、Ansys Icepak、Ansys Mechanical 和 Ansys Sherlock 作為全方位多重物理量解決方案,以便將 PCB 可靠度最佳化。

觀看此 Ansys Motion 的介紹影片,此為適用於多體動力學設計的最健全且進階的模擬解決方案。其可對柔性和剛性物體進行快速準確的分析。

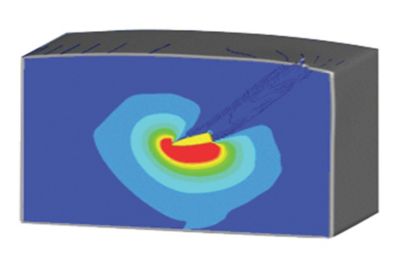

100 多年來,開模鍛造產品的領先供應商 Edelstahl Rosswag 已成功地為各行各業提供服務。其子公司 Rosswag Engineering 是該公司的積層製造 (AM) 部門。

Ansys 電子產品可靠度工作流程可協助您克服眾多電氣、熱和機械可靠度挑戰。這可讓您提升訊號完整性、防止衝擊和振動故障、消除電磁干擾等等。

對於 Ansys 來說,讓所有使用者 (包括身心障礙人士) 都能夠運用我們的產品至關重要。因此,我們致力於遵循美國無障礙委員會 (第 508 節)、無障礙網頁內容規範 (WCAG),以及自願性產品輔助工具範本 (VPAT®) 目前格式的各項無障礙規定。

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。