Quick Specs

Ansys partnered with HBK to bring unparalleled simulation-based durability technology to Ansys Workbench, providing end-to-end solutions for customers finding fatigue failure a key challenge.

Ansys nCode DesignLife, the industry-leading tool for durability analysis, gives you a comprehensive diagnostic fatigue process to predict your product’s operational lifetime.

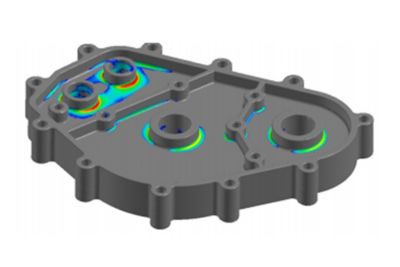

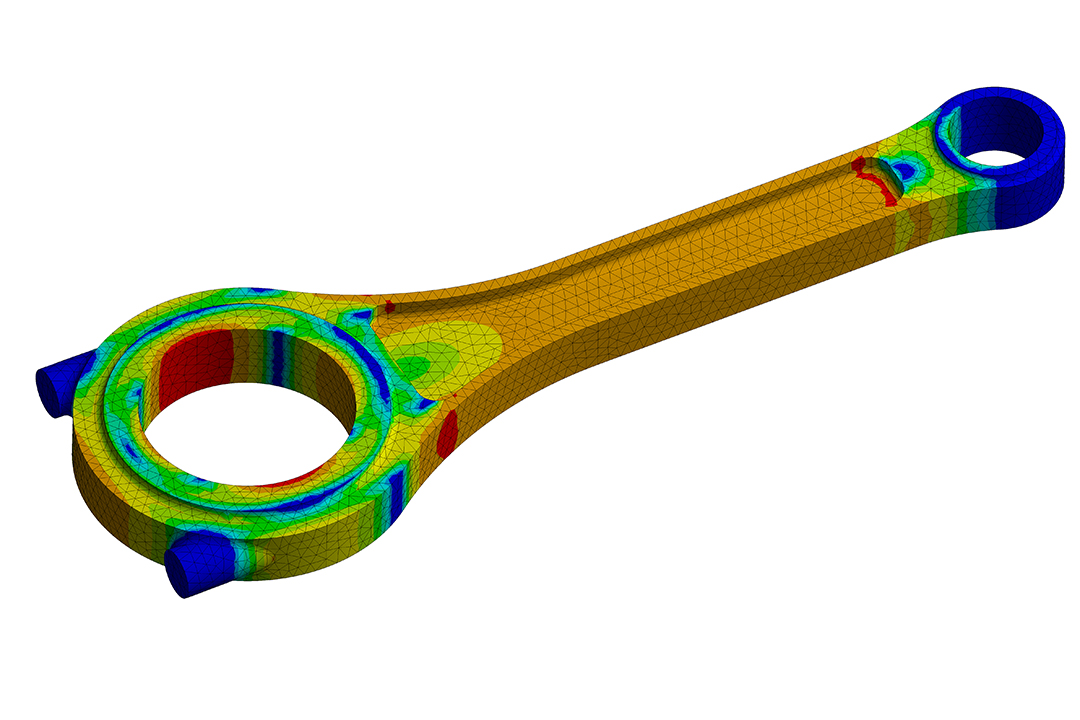

Ansys nCode DesignLife works with Ansys Mechanical to reliably evaluate fatigue life. Using the results of finite element analysis (FEA) from Ansys Mechanical and Ansys LS-DYNA, it accumulates damage from repetitive loading to determine a product’s predicted life. You can quickly evaluate the effects of different materials and alternative geometries for new designs, and then optimize them for the product’s expected usage — long before the first prototype is built or expensive testing takes place.

Ansys partnered with HBK to bring unparalleled simulation-based durability technology to Ansys Workbench, providing end-to-end solutions for customers finding fatigue failure a key challenge.

Ansys nCode DesignLife works with Ansys Mechanical and Ansys LS-DYNA to reliably evaluate fatigue life. You can quickly evaluate the effects of different materials and alternative geometries for new designs, and then optimize them for the product’s expected usage before a costly prototype.

With a new interface on the Ansys Workbench, you can enjoy a customized workflow that integrates with other products while staying within a single interface. You also have the flexibility to access your nCode user interface directly from Ansys Workbench. The ease-of-use makes the power of nCode DesignLife even easier to realize.

The new user interface provides an end-to-end solution within an integrated workflow and single interface

The standard EN method uses the Coffin-Manson-Basquin formula, defining the relationship between strain amplitude and the number of cycles to failure.

A wide range of methods are provided for defining the SN curves, including the ability to interpolate multiple material data curves for factors such as mean stress or temperature. Further options are also provided to account for stress gradients and surface finishes.

Output is the safety factor. The program uses material parameters calculated from tensile and torsion tests. Account for manufacturing effects by using equivalent plastic strain in the unloaded component.

This is widely used as a key design criterion for engine and powertrain components.

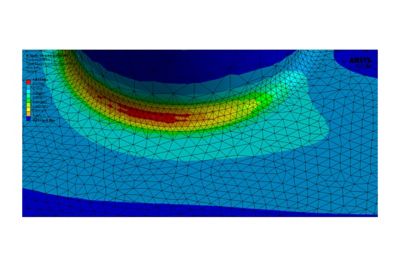

Covers seam welded joints including fillet, overlap and laser welded joints. Stresses can either be taken directly from FEA models (shell or solid elements) or calculated from grid point forces or displacements at the weld. The approach is appropriate for weld toe, root and throat failures.

Life calculations are made around a spot weld at multiple angle increments and the total life reported includes the worst case. Python scripting enables modeling of other joining methods such as rivets or bolts.

It provides the capability to predict fatigue in the frequency domain and is more realistic and efficient than time-domain analysis for many applications with random loading, such as wind and wave loads.

The Thermo-Mechanical Fatigue (TMF) option provides solvers for high-temperature fatigue and creep by using stress and temperature results from finite element simulations. TMF includes high temperature fatigue methods Chaboche and Chaboche Transient. Creep analysis methods include Larson-Miller and Chaboche creep.

The adhesive bonds option enables durability calculations on adhesive joints in metallic structures. Adhesive bonds are modeled with beam elements and grid point forces are used to determine line forces and moments at the edge of the glued flange. Approximate calculations of the strain energy release rate are made at the edge of the adhesive and, by comparison to the crack growth threshold, a safety factor is calculated.

NCODE RESOURCES & EVENT

Request this webinar to learn how Speos predicts the illumination and optical performance of systems, for both interior and exterior lighting, to help engineers reduce development time and costs while improving their product’s accuracy.

The Ansys platform is focused on an easy-to-use single UI, integration with industry-leading products and native automation.

Learn how Ansys Mechanical and Ansys nCode DesignLife can help ensure designs — early in development — meet fatigue specifications and will continue to perform beyond the warranty period.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。