주요 사양 요약

빠른 계산과 간소화된 데이터 입력 프로세스를 통해 Motor-CAD 사용자는 더 많은 모터 토폴로지를 탐색하고 전기 기계 설계의 초기 단계에서 고급 손실 효과의 영향을 완전히 평가할 수 있는 시간을 확보할 수 있습니다.

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

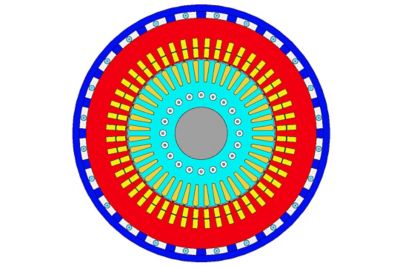

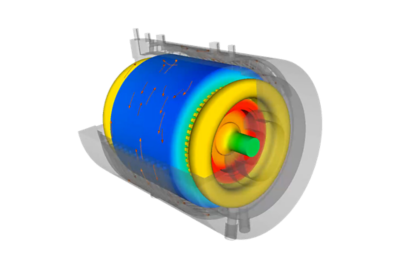

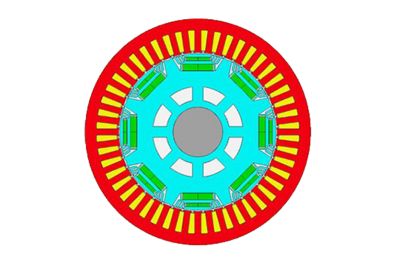

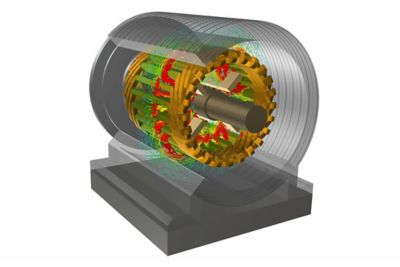

Ansys Motor-CAD는 전체 토크-속도 작동 범위에서 빠른 다중물리 시뮬레이션을 위한 전기 모터 설계 전용 툴입니다.

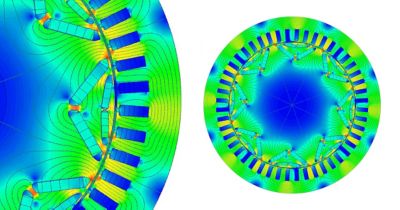

Motor-CAD는 설계 엔지니어가 전체 작동 범위에 걸쳐 모터 위상 배치와 구성 의도를 파악하여 성능, 효율 및 크기에 최적화 된 설계를 가능하게 합니다. Motor-CAD 소프트웨어의 4가지 통합 모듈인 전자기, Therm, Lab, Mech는 빠르고 반복적인 다중물리 계산을 가능하게 하여 사용자는 더 짧은 시간 안에 초기 설계에서 최종 설계까지 얻을 수 있습니다.

Ansys Motor-CAD는 전기 모터 설계 및 시뮬레이션을 위한 전문 툴입니다. Motor-CAD는 템플릿 기반의 직관적인 설정이 가능합니다. 따라서 내장된 전자기, 열 및 구조 솔버의 모터 설계에 대한 가치 있는 다중물리적 이해를 제공하고, 단순화하고 자동화된 해석 프로세스를 제공합니다.

빠른 계산과 간소화된 데이터 입력 프로세스를 통해 Motor-CAD 사용자는 더 많은 모터 토폴로지를 탐색하고 전기 기계 설계의 초기 단계에서 고급 손실 효과의 영향을 완전히 평가할 수 있는 시간을 확보할 수 있습니다.

2025년 7월

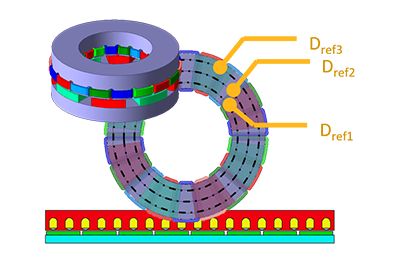

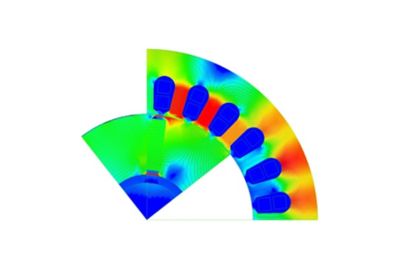

2025 R2 릴리스는 향상된 다중 슬라이스 등가 선형 모델링(ELM)을 통해 축 플럭스 모터 설계 정확도를 향상시킵니다. 개선된 기계 모듈은 구조적 무결성을 보장하기 위해 초기 응력 및 원심력을 평가하고, 권선형 로터 기계에 대한 향상된 비율 기반 모델링은 견고하고 형상을 인식하는 설계 탐색을 가능하게 합니다.

향상된 다중 슬라이스 지원은 축 플럭스 기계(AFM)에 대해 훨씬 더 정확한 설계 기능을 제공합니다. 이전 릴리스에서 도입되어 전자기 및 랩 모듈 내에서 단일 및 이중 토폴로지를 모두 지원하는 AFM 템플릿을 기반으로, 이러한 발전은 개발을 간소화하고 설계 충실도를 향상시킵니다.

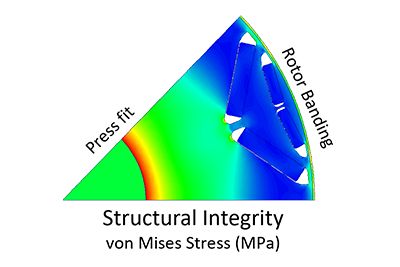

이제 기계 모듈을 통해 사용자는 초기 응력 및 원심력의 조합을 평가하고 계산하여 설계 주기 초기에 구조 성능에 대한 중요한 통찰력을 제공할 수 있습니다. 이 기능을 통해 엔지니어는 로터 밴딩 및 샤프트와 로터 적층 사이의 압입으로 인한 초기 장력의 기계적 무결성을 해결하여 더욱 견고하고 신뢰할 수 있는 제품 설계를 구현할 수 있습니다.

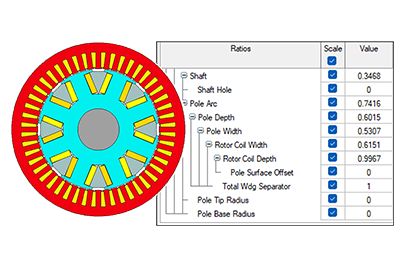

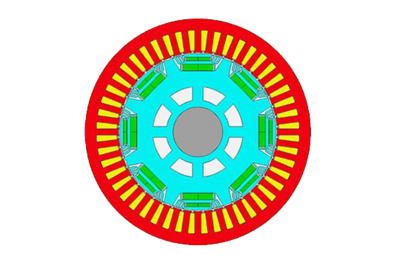

권선형 회전자 동기 모터(WRSM)를 위한 향상된 비율 기반 모델링은 설계 공간 탐색 중 견고한 기하학적 변화를 가능하게 합니다. 이는 대규모 매개변수 해석 및 설계 연구에 필수적이며, 모델 견고성을 보장하는 강력한 도구입니다.

Motor-CAD 기능

개발 주기가 점차 줄어들면서, 모터 설계자는 신속하게 설계 결정을 내려야 하며, 결정을 내림에 있어 문제가 발생하지 않도록 정확한 데이터와 예측이 기반돼야 합니다. 빠른 계산과 간소화된 데이터 입력 프로세스를 통해 Motor-CAD 사용자는 더 많은 모터 토폴로지를 탐색하고 설계의 초기 단계에서 고급 손실 효과의 영향을 완벽하게 평가할 수 있습니다.

Motor-CAD 소프트웨어의 직관적인 템플릿 기반 설정과 내장된 전문적인 다중물리 기술은 설계 프로세스를 간소화하고 특정 전자기, 열 또는 기계적 환경을 검토하기 위해 각 분야의 전문 엔지니어링 팀에 의존하지 않고서도, 전동기 설계 엔지니어 스스로 설계를 다양하게 검토하고 개발할 수 있습니다.

Motor-CAD는 고정밀 2D/3D 해석 기능을 제공하며, 사용자가 end-effects, 감자, 철손, 히스테리시스 및 기타 고급 전자기 현상을 분석하고 작동을 위한 온도 한계를 계산하고 완전한 모터 냉각 시스템을 설계할 수 있도록제공합니다.

Motor-CAD 자료 및 이벤트

Noise, vibration, and harshness(NVH)는 모터를 설계하고 최적화할 때 고려해야 하는 필수 요소입니다. Ansys optiSLang와 함께 Ansys Motor-CAD를 사용하여 모터의 전자기, 열 및 기계적 요구 사항에 따라 모터의 소음을 최적화하는 방법을 알아봅니다. 설계가 성숙함에 따라 Ansys Mechanical의 구조 정보로 빠른 분석 구조 모델을 개선하여 솔루션의 충실도를 높이는 동시에 솔루션 진행 속도를 높여 설계 최적화를 빠르게 수행할 수 있습니다.

Ansys Motor-CAD가 연속 토크/속도 특성 및 주행 사이클 효율을 포함한 전체 사양에서 다중물리 해석을 사용하여 유도 기기 설계안을 신속하게 평가하는 방법을 알아보십시오.

이 웨비나 시리즈는 개념 디자인, 개발, 냉각 시스템에서부터 소음, 진동 및 불쾌감(NVH) 또는 시스템 레벨 최적화에 이르는 전기 기계 설계의 모든 측면을 다루는 솔루션을 소개합니다.

전체 Ansys 모터 설계 흐름에 대한 개요 영상을 시청하십시오.

이 동영상은 FSAE 전기 및 태양광 차량을 염두에 두고 설계된 2부작 비디오 시리즈의 1부입니다. 이 동영상에서는 Ansys Motor-CAD를 사용한 모터의 기본 전자기 분석에 대해 알아봅니다.

이 동영상은 FSAE 전기 및 태양광 차량을 염두에 두고 설계된 2부작 비디오 시리즈의 2부입니다. 이 동영상에서는 Ansys Motor-CAD를 사용하여 토크, 인가 전류, 전압 구성, 효율맵 및 토크-속도 곡선과 같은 양을 계산하는 과정을 알아봅니다.

Ansys는 모든 사용자가 당사 제품에 액세스할 수 있다는 것을 가장 중요하게 생각합니다. 따라서 US Access Board(508조), Web Content Accessibility Guidelines(WCAG) 및 Voluntary Product Accessibility Template(VPAT)의 현재 형식에 근거한 접근성 요구 사항을 준수하기 위해 노력하고 있습니다.

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기