Quick Specs

Fast calculations and streamlined data input processes leave time for Motor-CAD users to explore more motor topologies and fully assess the impact of advanced loss effects in the initial stages of an electromechanical design.

Ansys empowers the next generation of engineers

Students get free access to world-class simulation software.

Design your future

Connect with Ansys to explore how simulation can power your next breakthrough.

Students get free access to world-class simulation software.

Connect with Ansys to explore how simulation can power your next breakthrough.

Ansys Motor-CAD is a dedicated electric machine design tool for fast multiphysics simulation across the full torque-speed operating range.

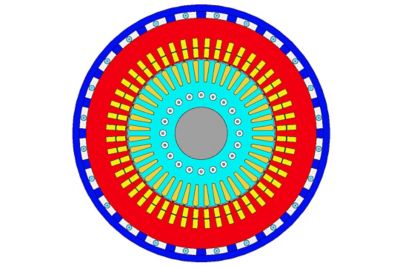

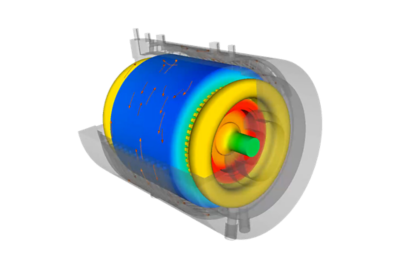

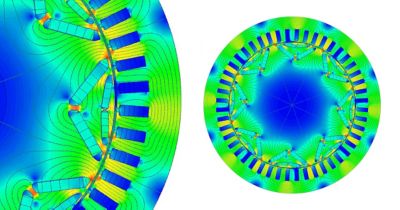

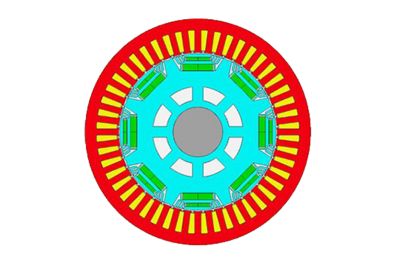

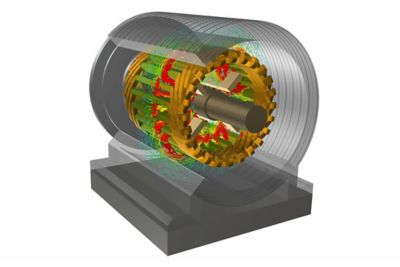

Motor-CAD enables design engineers to evaluate motor topologies and concepts across the full operating range, to produce designs that are optimized for performance, efficiency and size. Motor-CAD software’s four integrated modules—EM, Therm, Lab, Mech—enable multiphysics calculations to be performed quickly and iteratively, so users can get from concept to final design in less time.

Ansys Motor-CAD is a dedicated, industry-leading tool for electric motor design and simulation. Motor-CAD’s intuitive, template-based setup simplifies and automates the analysis process while its built-in electromagnetic, thermal and mechanical solvers offer valuable multiphysics insights into a motor design.

Fast calculations and streamlined data input processes leave time for Motor-CAD users to explore more motor topologies and fully assess the impact of advanced loss effects in the initial stages of an electromechanical design.

July 2025

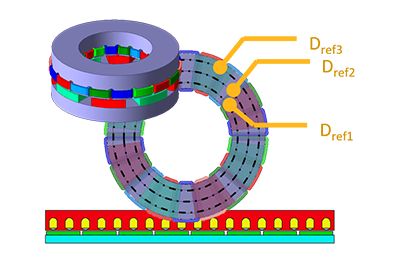

The 2025 R2 release boosts axial flux motor design accuracy with enhanced multi-slice equivalent linear modeling (ELM). The improved mechanical module assesses pre-stress and centrifugal forces early to ensure structural integrity, and the improved ratio-based modeling for wound rotor machines enables robust, geometry-aware design exploration.

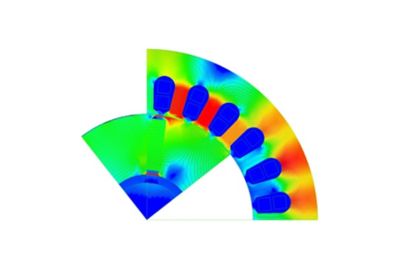

Enhanced multi-slice support delivers significantly more accurate design capabilities for axial flux machines (AFMs). Building on the AFM template introduced in the previous release, which supports both single and dual topologies within the electromagnetic and lab modules, this advancement streamlines development and enhances design fidelity.

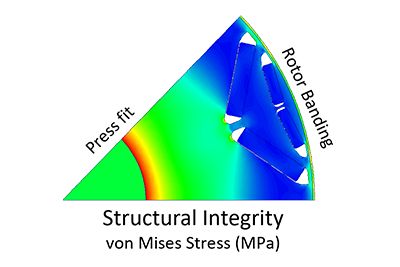

The mechanical module now enables users to evaluate and compute the combination of pre-stress and centrifugal forces, providing critical insights into structural performance early in the design cycle. This capability empowers engineers to address the mechanical integrity of pre-tension due to rotor banding and press fit between shaft and rotor lamination, driving more robust and reliable product designs.

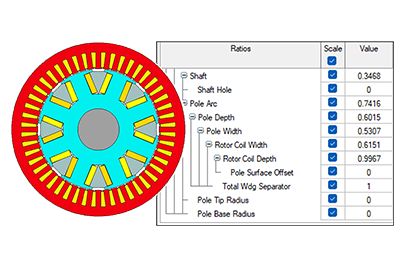

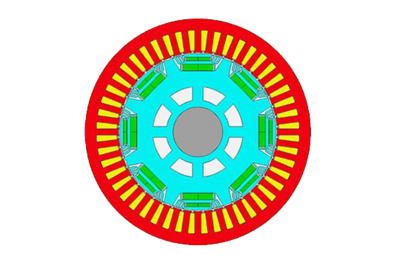

Enhanced ratio-based modeling for wound rotor synchronous machines (WRSMs) enables robust geometric variation during design space exploration. This is crucial for large-scale parametric analyses and design studies, and it is a powerful tool for ensuring model robustness.

MOTOR-CAD CAPABILITIES

With decreasing development cycles, motor designers need to make design decisions quickly, and with certainty that they will not face problems down the line. Fast calculations and streamlined data input processes leave time for Motor-CAD users to explore more motor topologies and fully assess the impact of advanced loss effects in the initial stages of a design.

Motor-CAD software’s intuitive, template-based setup and embedded multiphysics expertise simplifies the design process and reduces reliance on multiple teams for specific electromagnetic, thermal or mechanical experience — so motor designers can keep more control over their designs.

Motor-CAD delivers high-fidelity, 2D/3D analysis capability enabling users to analyze end-effects, demagnetization, core loss, hysteresis and other advanced electromagnetic phenomena, calculate the thermal envelope for operation and design complete motor cooling systems

MOTOR-CAD RESOURCES & EVENTS

Noise, vibration, and harshness (NVH) are essential aspects that must be considered when designing and optimizing a motor. Using Ansys Motor-CAD with Ansys optiSLang, we show how to optimize the motor’s noise alongside the motor’s electromagnetic, thermal, and mechanical requirements. As the design matures, structural information from Ansys Mechanical can improve the rapid analytical structural model, increasing the fidelity of the solution while maintaining the speedy solution times that allow fast design optimization.

Learn how Ansys Motor-CAD can rapidly evaluate a candidate induction machine design using multiphysics analysis against the complete specification, including continuous torque/speed characteristics and drive cycle efficiency.

This webinar series showcases solutions spanning all aspects of electric machine design - be it concept design and development, cooling system development, noise, vibration, and harshness (NVH), or system-level optimization.

Watch an overview of the complete Ansys motor design flow.

This is part one of a two-part video series designed with FSAE Electric & Solar teams in mind. In this video, you will learn the basic electromagnetic analysis of a motor using Ansys Motor-CAD.

This is part two of two-part video designed with FSAE Electric & Solar vehicles in mind. In this video, the process of calculating quantities such as torque, winding current, voltage plots, efficiency maps & torque speed curves will be demonstrated using Ansys Motor-CAD.

It's vital to Ansys that all users, including those with disabilities, can access our products. As such, we endeavor to follow accessibility requirements based on the US Access Board (Section 508), Web Content Accessibility Guidelines (WCAG), and the current format of the Voluntary Product Accessibility Template (VPAT).

If you're facing engineering challenges, our team is here to assist. With a wealth of experience and a commitment to innovation, we invite you to reach out to us. Let's collaborate to turn your engineering obstacles into opportunities for growth and success. Contact us today to start the conversation.