-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

ANSYS ADVANTAGE MAGAZINE

January 2021

Fast Tracking Next-Gen Electric Traction Motors

By Eng. Luca Boscaglia, Ph.D. Candidate – Electrical Motors Designer for Vehicle Applications, Chalmers University of Technology, Gothenburg, Sweden

When you hear the train coming down the track, traction motors are driving those wheels. Rail systems engineers have been tasked with creating an enhanced, highpowered electrical traction motor with torque density, which will help trains run more efficiently, consume less fuel, produce fewer emissions and reduce overall energy consumption.

To accomplish this, motor thermal performance must be improved. But this isn’t easy because metropolitan trains typically only have a small, confined environment to house a motor. As a result, motors are becoming increasingly compact and are required to produce more power in the same volume, leaving less space for cooling. Additionally, motors must be able to provide the specified power without overheating critical components and decreasing the operational efficiency. Not having an established methodology for assessing the motor’s thermal performance early in the design phase presented an obstacle that ABB engineers needed to overcome.

For this, a team composed of ABB, Ansys and Politecnico di Torino turned to Ansys Fluent which delivered tremendous modeling accuracy and enabled engineers to assess hotspots across critical components, including the end windings, stator slots and rotor bars. However, engineers needed a faster way to compute the thermal BTU. By coupling Fluent with Ansys Twin Builder’s dynamic reduced-order modeling (ROM), they could rapidly and accurately analyze the thermal behavior of electric traction motors along their full duty cycles.

A ROM gave the team a way to obtain thermal performance results extraordinarily fast. This empowered ABB engineers to examine a motor model, select random operational parameters and quickly demonstrate the behavior of a traction model in response. Normally, with a traditional solver, this would require many hours or even days. Using a dynamic ROM, engineers accomplished this task in just a few milliseconds.

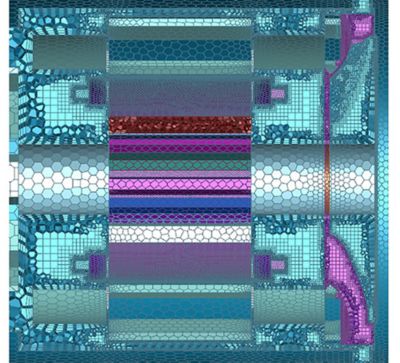

Cross-sectional view along the axial direction of the CFD mesh

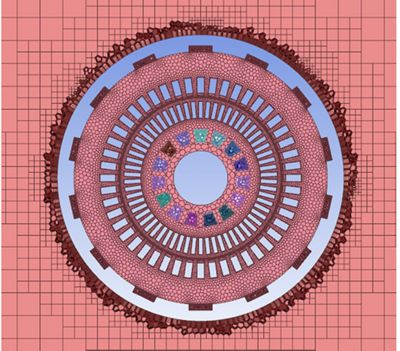

Cross-sectional view along the radial direction of the CFD mesh

Creating the Design in Fluent

After Ansys SpaceClaim was used to clean up the computer-aided design (CAD) geometry and extract the fleet volumes to prepare the model, ABB engineers imported it into Fluent to measure the thermal distribution across both fluid volumes and solid parts in steady state. Here, a single conjugate heat transfer (CHT) analysis helped engineers accurately predict thermal performances by leveraging both CFD and heat transfer models in less than 10 minutes with simulation. This helped Politecnico di Torino analysts explore several different design conditions in terms of boundary conditions and operating conditions, build their reference model and run several design configurations.

Usually the pre-processing phase is the most demanding stage of a CHT analysis, requiring engineers to check the quality of the mesh elements. Instead, Fluent Mosaic meshing did most of that heavy lifting while keeping elements to a minimum to drive fast, accurate results.

To make the reference models run faster, ABB leveraged high-performance computing (HPC). Simulating the full duty cycle — the full transient simulation — across more than 32 cores required 17 days to generate traditional models with 99% accuracy. HPC proved invaluable for generating this machine learning training data, which engineers used to build the ROM.

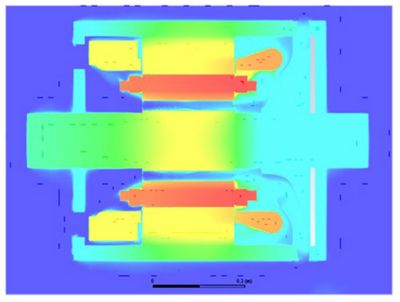

Cross-sectional view along the radial direction of the temperature distribution computed by CFD

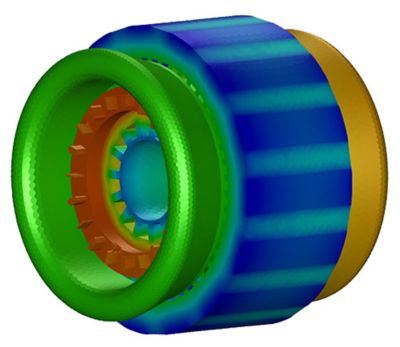

Temperature distribution on stator, windings and rotor computed by CFD

Building the ROM in Ansys Twin Builder

The ROM is a simplified, compressed version of a reference model that reduces the time required to optimize and simulate a complex system while preserving the essential accuracy. Exploring design alternatives 10 to 100 times faster than a reference model with similar accuracy, the ROM enabled high-confidence prediction of motor thermal behavior in duty cycles with a high number of operating points.

After engineers properly designed, manufactured and deployed the physical prototype of the electric motor, they put it to the test with the ROM. They ran the simulation model of the motor in parallel and in real time against the prototype as it ran down the track. This would not have been possible with a traditional solver, which takes hours to run at a minimum. Instead, the ROM ran the simulation in milliseconds, so engineers could predict any motor failures and improve operations in real time.

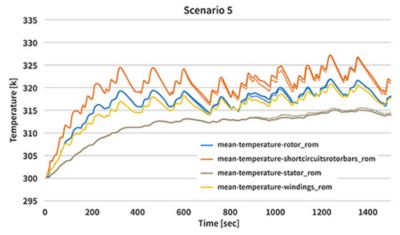

A dynamic ROM was primarily created for the transient simulation because engineers needed to capture the thermal response of the electric motor to predict motor thermal behavior during a full duty cycle with a high number of operating conditions that change over time.

Running a dynamic ROM was key for engineers to understand the motor’s behavior as it provided different levels of power dissipation in response to thermal inertia and various transient effects during a typical duty cycle. For example, consider a subway train that begins moving from its first stop. First, there’s an acceleration phase, followed by a cruise phase and then a braking phase to reach the next scheduled stop. During these phases, the temperatures of several motor components change continuously and differently, and this process repeats for 10 to 20 stops along the track as the subway crosses a city. When the train parks, the motor stops, and its varying thermal load must be cooled down.

Ultimately, the dynamic ROM provided insight into countless operational scenarios a train might encounter, ranging from traversing up and down hills to managing the slickness of a wet track.

After an extensive optimization of the model, the main engineers were able to the run the ROM in mere milliseconds, saving themselves tremendous amounts of time, without trading speed for accuracy. In fact, the deviation of the ROM in estimating the motor thermal performance was less than 1 C from the full order reference model.

CFD vs. ROM comparison for the transient thermal responses

Verifying the Design

Next, ABB engineers conducted experimental temperature measurements to compare the full CHT results with the data received from the prototype motor’s thermocouple sensors. ABB found that the deviation between the mass flow rate of the coolant (air) measured from the experimental results and model was within a 5% margin of error, demonstrating the accuracy of the CFD analysis. ABB engineers also proved that the temperatures in steady state measured in the experimental setup matched up well with those in the Ansys model.

Once the prototype motor and the ROM were completed, engineers ran the two against each other. As the prototype motor raced down the track, engineers compared it with its ROM counterpart. Because the thermal model of the prototype was tested and validations were carried out for both CFD and heat transfer, demonstrating an error of the model within the 5% range, ABB engineers now have a template model procedure they can use to optimize the thermal design of future motors.

This data was used to create a model to forecast the thermal behavior of future machines during the design stage. As a result, the development team can radically reduce the number of physical prototypes built, reducing computational time from days and weeks to seconds.

CITATION

This article references research conducted by L. Boscaglia, F. Bonsanto, A. Boglietti, S. Nategh and C. Scema: "Conjugate Heat Transfer and CFD Modeling of Self-ventilated Traction Motors," 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, Md., USA, 2019, pp. 3103-3109, doi: 10.1109/ ECCE.2019.8913138

시작하기

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기