-

-

학생용 무료 소프트웨어에 액세스하기

차세대 엔지니어에게 힘을 실어주는 Ansys

학생들은 세계적 수준의 시뮬레이션 소프트웨어를 무료로 이용할 수 있습니다.

-

지금 바로 Ansys에 연결하십시오!

미래를 설계하기

시뮬레이션이 다음 혁신을 어떻게 지원할 수 있는지 알아보려면 Ansys와 연결하십시오.

국가

무료 트라이얼

제품 및 서비스

학습하기

회사 정보

Back

제품 및 서비스

ANSYS BLOG

April 18, 2019

Combining Embedded Software Development, Reliability and Functional Safety Assessments in One Workflow

The electrification of automotive, aerospace and healthcare products offers customers more functionality, safety features and reliability. However, electrification initiatives can complicate development cycles. This complexity makes it difficult for engineers to optimize the embedded software and functional safety of their products.

For instance, engineers need to ensure that the embedded software running the rearview camera coordinates with the embedded software running the antilock braking system in an emergency situation.

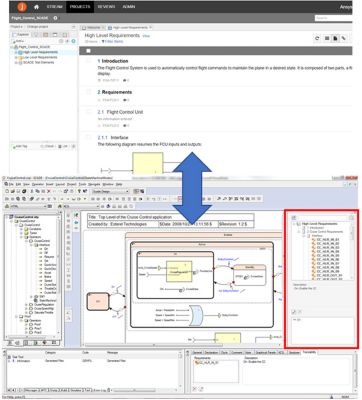

Jama requirements expressed in ANSYS medini analyze

Traditionally, disparate teams work on the embedded software development, performance reliability and functional safety of these electrification initiatives. This siloed product development approach can lead to lost information and last-minute redesigns. As a result, siloed product development teams will have a hard time meeting deadlines and maintaining the trackability and documentation needed for product certifications.

To address these challenges, Ansys and Jama Software have partnered together to offer tools that help development teams collaborate on the development, reliability and functional safety of their products.

How Collaboration Improves Functional Safety and Embedded Software Workflows

Product development teams can use Jama Connect to manage the regulatory requirement workflow.

First, the quality and safety analyses requirements are determined within Ansys SCADE or Ansys medini analyze. These requirements are then passed onto Jama Connect where development teams can ensure they are met.

Since teams are working in a single workflow, they are better able to pass information, collaborate and get products to market faster.

Jama requirements expressed in ANSYS SCADE

The added communication increases the likelihood that errors will be flagged and corrected earlier in development — saving time and development costs.

Jama Connect also updates design changes automatically. This improves audit trails, documentation and certification processes.

To learn more about how SCADE, medini analyze and Jama Connect are necessary tools to meet quality and safety standards, download the white paper: Integrating Product Development with Safety Analyses: A Value-Added Approach.