Quick Specs

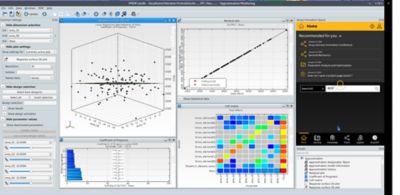

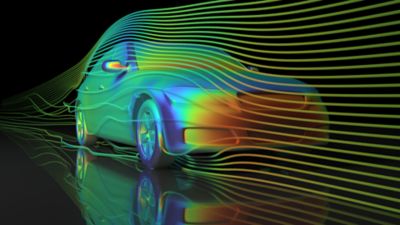

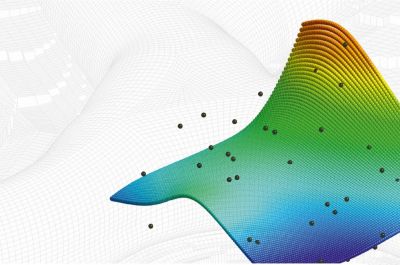

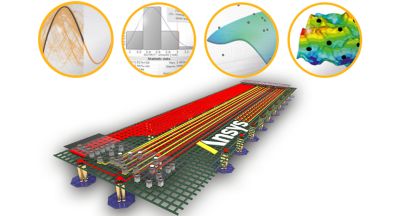

Accelerate searches for the best and most robust design configuration by automating the search process with interactive visualization and AI technologies. State-of-the-art algorithms for design exploration, optimization, robustness and reliability analysis let you make better decisions with less effort using design optimization software.