透過模擬進行設計最佳化及植入物個人化

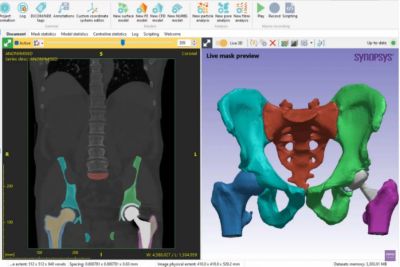

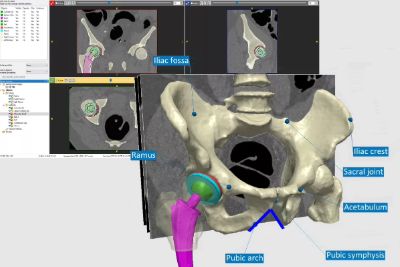

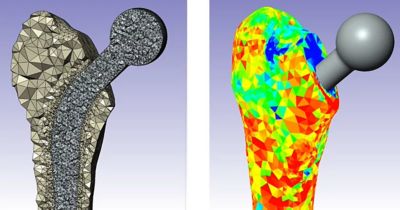

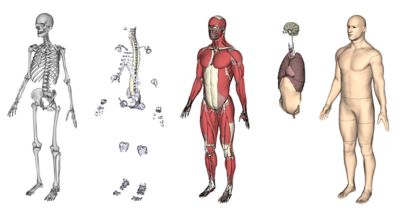

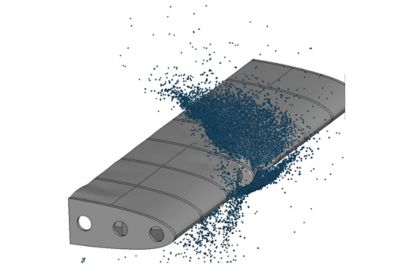

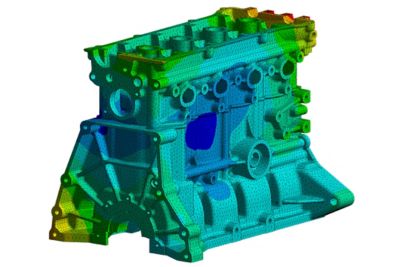

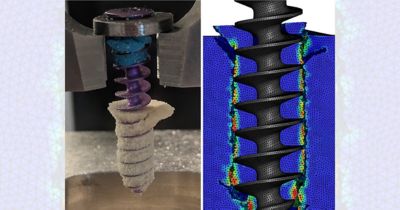

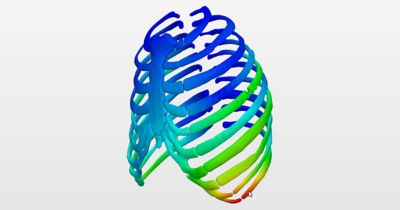

隨著預期壽命日益增加,植入物也開始應用至較為年輕的病患身上,各家企業於是競相延長其醫療器材的使用壽命。業界已針對老化的髖關節、膝關節、肩關節及脊椎等部位,持續發展創新性置換療法。Ansys (現已與Synopsys合而為一) 提供電腦模擬技術,例如計算建模與模擬 (CM&S)、人工智慧 (AI) 及數位孿生,將多重物理量模擬技術結合組織、材料、病患專屬生理條件、手術程序及製程等模型。

每名病患都是獨立的個體,模擬技術可以讓義肢及植入物設計與開發工作,針對一般人口涵蓋的龐大群體進行調整,或是按照病患的專屬需求將其客製化。

精選解決方案

精選產品

電腦模擬醫學興起

以下精選整理的成功案例與前瞻觀點,來自全球運用模擬技術推動醫療發展的同事、客戶與合作夥伴。

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。