-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

THEMENDETAILS

Was sind Hardware-in-the-Loop-Tests?

Hardware-in-the-Loop(HIL)-Tests sind eine Technik, die von Ingenieur*innen zum Testen und Validieren von Software eingebetteter Systeme verwendet wird. HIL funktioniert, indem eine Steuereinheit, auf der die Software ausgeführt wird, mit einer genauen Simulation der Sensoren und Aktoren, die von einem eingebetteten System gesteuert werden, elektronisch verbunden wird.

Das simulierte System kann sowohl aus virtuellen als auch aus physischen Modellen bestehen, die reale Systeme darstellen. Ingenieur*innen verwenden HIL-Testsysteme, um die Funktionalität ihrer Software in Echtzeit in einer kontrollierten Umgebung zu testen, bevor sie ihre Lösung in realen Fahrzeugen, Maschinen, Geräten oder Systemen einsetzen. Da die verwendeten Produkte und Softwares immer komplexer werden und sicherheitskritische Anwendungen erfordern, hat die Bedeutung von HIL-Tests zugenommen.

Komponenten in einer Hardware-in-the-Loop-Simulation

Die Hauptkomponenten eines Hardware-in-the-Loop-Simulationssystems sind entweder Teil des Steuergeräts, der Simulationsanlage oder der simulierten Hardware (manchmal auch als digitale Zwillinge bezeichnet). In Kombination erzeugen diese Komponenten eine Echtzeitsimulation des Steuerungssystems in einem geschlossenen Regelkreis.

Steuerungssoftware

Die zu testende Software ist die Hauptkomponente der Steuereinheit im Testaufbau. Sie besteht aus dem tatsächlich auf die Hardware geladenen Code und ist der Softwareteil der Steuereinheit.

Elektronisches Steuergerät (ECU)

Das elektronische Steuergerät ist das Gerät, das die Software ausführt und der von ihm gesteuerten Anlage Eingaben und Ausgaben (E/A) bereitstellt. Ein wesentlicher Vorteil von HIL-Tests besteht darin, dass die Software auf der realen Elektronik-Hardware geprüft wird, auf der sie nach der Implementierung ausgeführt wird.

HIL-Simulationssystem

Im Endprodukt ist die Steuereinheit direkt mit Sensoren und Geräten verbunden. Für eine HIL-Testumgebung verbinden spezielle HIL-Geräte und Software von Unternehmen wie National Instruments (NI) oder dSPACE die Komponenten, die die eigentliche Anlage simulieren, mit einem ECU. Dieses System wird auch als HIL-Testsystem bezeichnet und bietet Testmanagement, E/A-Konfiguration und Automatisierungstools. Es kann aus einer oder mehreren Einheiten bestehen.

Virtuelle Komponenten

Tester*innen verwenden mathematische Darstellungen einiger Subsysteme, auf die sie keinen Zugriff haben, oder Systeme, die sie nicht so schnell oder einfach simulieren können wie echte Hardware. Jede virtuelle Komponente kann Befehle und Dateneingaben empfangen und dieselben elektrischen Ausgaben erzeugen wie das eigentliche System, entweder digital oder analog. Diese virtuellen Simulationen können so einfach wie eine Gleichung sein und so komplex wie eine multiphysikalische Simulation eines auf einem Satelliten im Orbit montierten Antennensystems.

Physische Komponenten

Bei vielen Systemtestkonfigurationen wird reale Hardware verwendet, bei der es sich um das Endprodukt, einen Prototyp oder eine physische Darstellung eines Subsystems handeln kann. Simulierte Systeme können jedoch auch physische Komponenten enthalten, die mit virtuellen Komponenten verbunden sind. Dies ist insbesondere bei Systemen üblich, bei denen die Sensoren mittels einer virtuellen Version in der Hardwareschleife dargestellt werden.

Der Unterschied zwischen Software-in-the-Loop- und Hardware-in-the-Loop-Tests

Viele komplexe Steuerungssysteme, insbesondere sicherheitskritische, verwenden eine HIL ähnelnde Technik, die als Software-in-the-Loop(SIL)-Test bezeichnet wird. Bei HIL wird physische Hardware für die E/A verwendet, während bei einem SIL-System ein Software-Tool eingesetzt wird, um das Verhalten des Mikroprozessors oder des FPGA (Field-Programmable Gate Array) des Steuergeräts und das Netzwerk der elektrischen Verbindungen für die E/A zu emulieren.

SIL wird in der Regel zu einem frühen Zeitpunkt des Produktentwicklungsprozesses durchgeführt, bevor das physische ECU verfügbar ist. Softwareentwicklungsteams nutzen SIL zur Validierung von Algorithmen, Logik und allgemeinem Softwareverhalten, bevor sie in echte Hardware integriert werden. SIL ermöglicht kostengünstige Tests ohne physische Hardware oder physischen Speicherplatz.

Doch selbst wenn Teams gründliche SIL-Tests durchführen, sind HIL-Tests immer noch erforderlich, da die Software auf dem ECU und mit realen Signalen, einschließlich Latenz und Rauschen, validiert werden muss. Viele Anwendungsfälle beziehen sich auf das Verhalten von Steuergeräten, das die Software nicht simulieren kann. HIL-Tests stellen sicher, dass Hardware und Software für Sicherheitstests zusammenarbeiten und den Branchenstandards entsprechen, die in der Luft- und Raumfahrt, der Medizin und der Automobilindustrie üblich sind.

Die Vorteile von Hardware-in-the-Loop-Tests

Hardware-in-the-Loop-Tests bieten erhebliche Vorteile in Bezug auf Zeitplan, Kosten, Sicherheit und Leistung. In einigen Branchen sind sie sogar für die Zertifizierung erforderlich. Die Wirksamkeit dieser Vorteile hängt von der Genauigkeit der verwendeten Simulationen, den Kosten für die Erstellung dieser Simulationen in Hard- oder Software, der potenziellen Automatisierung zeitaufwendiger Schritte sowie der Gründlichkeit und Effizienz des Testplans ab.

Zu den bedeutendsten Vorteilen der HIL-Simulation gehören:

Zeitersparnis

HIL kann den Entwicklungsplan eines Produkts auf verschiedene Arten verbessern. Der wichtigste Vorteil besteht darin, dass HIL-Tests viel schneller sind, sodass Tests rund um die Uhr mit mehreren Prüfständen parallel ausgeführt werden können. Eine weitere Verkürzung der Entwicklungszeit umfasst die Einführung von HIL-Tests zu einem früheren Zeitpunkt im Entwicklungsprozess. Teams können Probleme frühzeitig erkennen, sodass sie sich nur geringfügig auf den Produktionsplan auswirken. Durch HIL ermöglichte Automatisierungsoptionen verkürzen auch den Zeitaufwand für die Durchführung von Tests. Am wichtigsten ist jedoch, dass HIL die Markteinführungszeit eines Produkts erheblich verkürzen kann.

Da es in der Regel eine begrenzte Anzahl von vollständigen physikalischen Prototypen gibt, können nur wenige Tests gleichzeitig durchgeführt werden. Mit HIL-Tests können Ingenieur*innen mehr Tests parallel durchführen, um den Entwicklungszyklus erheblich zu verkürzen.

Kosteneinsparungen

Der positive Einfluss von HIL auf den Entwicklungsplan eines Produkts trägt auch zur Kostensenkung bei. Darüber hinaus macht die hochgradig skalierbare Art dieser Testtechnik die Durchführung mehrerer Tests wesentlich kostengünstiger. Darüber hinaus kann die Verwendung von HIL die Kosten für die Herstellung der physischen Hardware und Software, die für die endgültige Anlagenkonstruktion erforderlich ist, entfallen lassen oder reduzieren. Die Automatisierung für mehrere Testszenarien reduziert außerdem den Arbeitsaufwand und die Zeit in der Testzelle bzw. die Zeit, in der Hardware-Setups verwendet werden.

Konsistente, reproduzierbare Tests

Die Entwicklung robuster Steuerungsalgorithmen ist einfacher, wenn Ingenieur*innen ihre Ideen auf konsistente und reproduzierbare Weise testen können. Die unkontrollierte und unvorhersehbare Umgebung von Praxistests kann zu großen Schwankungen führen.

Erhöhte Bestehensquote beim finalen Produkttest

Nur wenige Dinge in einem Entwicklungsprogramm sind so teuer und schädlich für einen Produktionsplan wie das Nichtbestehen einer abschließenden Zertifizierung oder eines Leistungstests. Wenn ein Testprozess sowohl SIL- als auch HIL-Tests umfasst, können die meisten Fehlermodi frühzeitig erkannt und behoben werden.

Sicherheitsvalidierung in einer sicheren Testumgebung

Viele Systeme, die über eingebettete Systemsoftware gesteuert werden, erfordern Tests zur Sicherheitsvalidierung. Viele Systeme können jedoch nicht in einer sicheren Umgebung getestet werden. Zum Beispiel erfordert das Testen eines erweiterten Fahrerassistenzsystems (Advanced Driver Assistance Systems = ADAS), dass ein Fahrzeug in gefährliche Situationen gebracht wird, um zu prüfen, wie das ADAS reagiert. Das ist nicht nur teuer, sondern auch gefährlich für die Fahrer*innen. Außerdem kann das Fahrzeug beschädigt werden. HIL-Tests mit virtuellen Komponenten und Testautomatisierung beseitigen diese Gefahr für Tester*innen, validieren die Sicherheit des Systems und senken die Kosten.

HIL-Tests in allen Branchen

Jedes Produkt, das eingebettete Systemsoftware für die Gerätesteuerung verwendet, kann von HIL-Tests als Teil des Designprozesses von Steuerungen profitieren. Einige Industrien werden jedoch stärker davon profitieren als andere, da die oben genannten Vorteile in ihren Produktionsprozessen bedeutender sind. Hier sind sechs wichtige Branchen, in denen Hardware-in-the-Loop-Tests weit verbreitet sind:

1. Automobilindustrie

Die Automobilindustrie ist einer der intensivsten Anwender von HIL, insbesondere angesichts des wachsenden Trends hin zur Entwicklung softwaredefinierter Fahrzeuge (SDVs). Die Kosten- und Sicherheitsprobleme im Zusammenhang mit realen Fahrzeugtests, ganz zu schweigen von der langen Vorlaufzeit, bis ein Prototyp verfügbar ist, machen HIL zu einem wichtigen Teil des Fahrzeugdesigns.

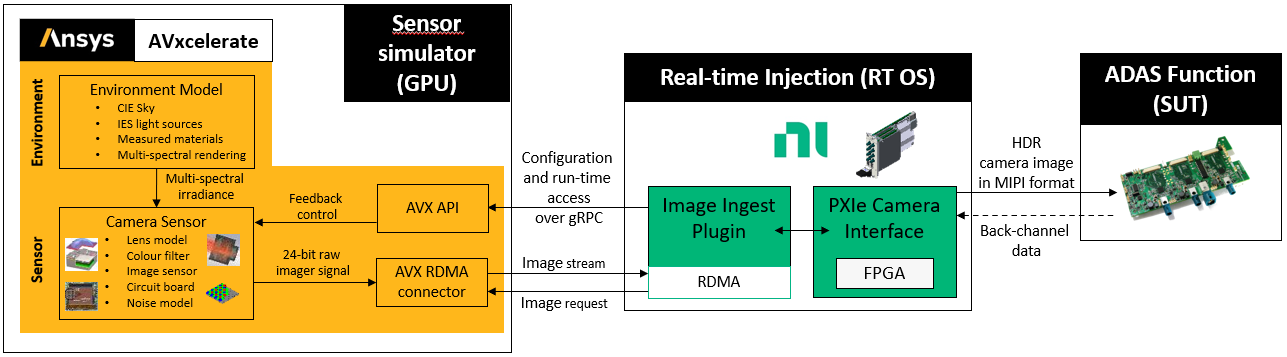

Beispielsweise kann HIL zum Testen der in einem ADAS-System verwendeten Kamera eingesetzt werden. Die Ansys AVxcelerate Sensors-Software und das RDMA von NI können das Rohsignal von der Kamera eines virtuellen Autos erzeugen, dieses in ein Signal umwandeln, das die eingebettete Verarbeitung der Kamera sehen wird, und dann die Ausgabe von diesem Subsystem an das ECU weiterleiten.

2. Luft- und Raumfahrt

Drei der größten Herausforderungen bei der Entwicklung von Steuerungssystemen für Anwendungen in der Luft- und Raumfahrt sind die strenge Einhaltung von Spezifikationen, die Kosten für die Herstellung von Hardware sowie die Probleme und Kosten beim Testen physischer Module in der Luft- und Raumfahrt vor Ort. Jede dieser Herausforderungen macht HIL zur bevorzugten Testmethode. Es wird häufig für die Zertifizierung benötigt. Die Einführung autonomer Systeme in der Luft- und Raumfahrt erhöht nur den Bedarf an HIL.

3. Antrieb und Stromerzeugung

Kraftwerke, die Energie für elektrische Systeme oder mechanische Antriebe erzeugen, profitieren vom Einsatz eingebetteter Systemsteuerungen. ECUs in solchen Anwendungen verwenden Sensoren, die Betriebsbedingungen erkennen und Befehle senden, um Effizienz, Zuverlässigkeit und Energieerzeugung zu optimieren. Das kann so einfach sein wie die Leistungselektronik für die Energieerzeugung oder so komplex wie die Überwachung und Minimierung der Verschmutzung in einem Erdgaskraftwerk.

4. Industriemaschinen und Robotik

Eine wachsende Zahl an Herstellern von Industriemaschinen und Produktionsstätten, die industrielle Geräte einsetzen, einschließlich Robotik, nutzen HIL-Simulation, um die Effizienz von Maschinen oder des Fertigungsprozesses zu optimieren, bevor eine neue Produktionslinie aufgebaut wird.

5. Medizinische Geräte und medizinische Diagnostik

Der zunehmende Einsatz intelligenter Geräte, eine strenge Sicherheitszertifizierung sowie die praxisbezogenen Herausforderungen bei Tests in der Medizinbranche sorgen dafür, dass auch hier Entwicklungsteams zunehmend HIL-Tests einsetzen. Eingebettete Software kann in sicherheitskritischen Systemen wie Herzschrittmachern oder Insulininjektionsgeräten überprüft werden, indem HIL frühzeitig im Designprozess sowie in der Verifizierungs- und Validierungsphase verwendet wird.

6. Batteriemanagementsysteme

Wenn HIL-Tests auf Batteriemanagementsysteme (BMS) angewendet werden, kann dies die Batterieentwicklung in Anwendungen in der Automobilindustrie, in der Luft- und Raumfahrt und in der Stromerzeugung beschleunigen. Die Closed-Loop-Validierung von BMS in einer HIL-Umgebung stellt sicher, dass alle Sicherheits- und Leistungsfunktionen fehlerfrei arbeiten. Ein Modell auf Batteriesystemebene, das mittels CAE-Simulationen (CAE = Computer-Aided Engineering) entwickelt wurde, kann in HIL-Systeme integriert werden, um die physische Batterie darzustellen. Es kann auch mit physischen Batteriesystemen verbunden werden, um die BMS-Leistung unter verschiedenen Bedingungen wie Überspannung, Überstrom, Überhitzungswarnung, Zellenausgleich, Kurzschlussreaktion und anderen kritischen Ereignissen zu überprüfen, für die das BMS ausgelegt ist.

Die Rolle der numerischen Simulation bei der HIL-Prüfung

Die numerische Simulation, insbesondere die in der Ansys Multiphysics-Software enthaltenen Tools, spielt bei den meisten HIL-Simulationen eine wichtige Rolle. Wenn eine einfache Gleichung oder Suche nach empirischen Daten nicht die erforderliche Genauigkeit oder den erforderlichen Bereich liefert oder wenn die Verwendung einer physikalischen Simulation nicht praktikabel oder kosteneffizient ist, bietet die numerische Simulation eine Lösung.

Der Vorteil der numerischen Simulation liegt in ihrer großen Genauigkeit. Darüber hinaus verfügen Ingenieur*innen möglicherweise bereits über Modelle der Hardware und das Team kann die Auswirkungen des Steuerungssystems auf dieses Modul im System erfassen.

Im Folgenden finden Sie einige Möglichkeiten, virtuelle Komponenten in einer HIL-Studie zu verwenden:

Fortschrittliche Fahrerassistenzsysteme und autonome Fahrzeuge (AV = Autonomous Vehicles)

Die Modellierung von Fahrzeugen in vielen Fahrsituationen in Verbindung mit dem Input von Sensoren, die Sensoren aus der Praxis genau imitieren, ist der Schlüssel für HIL-Tests bei der Entwicklung von ADAS/AV-Lösungen. Aus diesem Grund wird eine ganze Suite digitaler Modellierungstools wie Ansys AVxcelerate-Lösungen von Ingenieur*innen aus der Automobilindustrie verwendet, um Eingaben für eingebettete Systemsoftware zu modellieren.

Zwei großartige Beispiele sind die Ansys AVxcelerate Sensors-Software zur Modellierung von Kamera- und Lidar-Eingaben sowie die Ansys AVxcelerate Headlamp-Software, die Ingenieur*innen zeigt, wie Änderungen an Scheinwerfern für Fahrer*innen, andere Fahrzeuge und Fußgänger*innen tatsächlich aussehen.

Integration

Unabhängig davon, wie die numerischen Simulationsmodelle Ergebnisse aus den bereitgestellten Eingaben generieren, müssen diese an das HIL-System übergeben werden. Eine einfache Möglichkeit dazu ist die Verwendung von Skriptfunktionen wie PyAnsys, um Software über die Python-Sprache zu verbinden. Ein modellbasiertes System Engineering (MBSE)-Tool wie Ansys ModelCenter-Software oder die Ansys Thermal Desktop-Plattform (AEDT) bietet einen genauen Überblick über das Echtzeitverhalten auf Systemebene.

Modellierung mechanischer Komponenten

Eine häufige Ergänzung zu den digitalen Komponenten in einer HIL-Simulation sind numerische Gleichungslöser, die das strukturelle, thermische und dynamische Verhalten von Komponenten darstellen. Für diesen Zweck kann ein Universaltool wie Ansys Mechanical-Software oder eine spezielle Lösung wie Ansys Motion-Software für die Mehrkörperdynamik verwendet werden. Darüber hinaus können Ingenieur*innen ein Tool wie die Ansys optiSLang-Software verwenden, um Modelle mit reduzierter Ordnung (ROMs) zu generieren, die in ein MBSE-Systemmodell eingefügt werden können.

Modellierung elektromagnetischer Komponenten

Elektromagnetische Sensoren und Aktoren spielen in vielen Systemen, die mit eingebetteter Systemsoftware betrieben werden, eine wichtige Rolle. Daher werden schnelle und genaue Tools zur elektromagnetischen Modellierung wie Ansys Maxwell-Software und Ansys HFSS-Software oft als digitale Komponenten in die Anlage integriert.

Wenden Sie sich noch heute an eine Kontaktperson von Ansys, um zu erfahren, wie unsere branchenführenden Softwarelösungen Ihnen helfen können.

Zugehörige Ressourcen

Los geht's

Wenn Sie mit technischen Herausforderungen konfrontiert sind, ist unser Team für Sie da. Mit unserer langjährigen Erfahrung und unserem Engagement für Innovation laden wir Sie ein, sich an uns zu wenden. Lassen Sie uns zusammenarbeiten, um Ihre technischen Hindernisse in Chancen für Wachstum und Erfolg zu verwandeln. Kontaktieren Sie uns noch heute, um das Gespräch zu beginnen.