-

-

Kostenlose Software für Studierende

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

-

Verbinden Sie sich jetzt mit Ansys!

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Länder und Regionen

Kostenlose Demoversionen

Produkte & Dienstleistungen

Lernportal

Über das Unternehmen

Back

Produkte & Dienstleistungen

Back

Lernportal

Ansys unterstützt die nächste Generation von Ingenieur*innen

Studenten erhalten kostenlosen Zugang zu erstklassiger Simulationssoftware.

Back

Über das Unternehmen

Gestalten Sie Ihre Zukunft

Stellen Sie eine Verbindung mit Ansys her, um zu erfahren, wie Simulation Ihren nächsten Durchbruch vorantreiben kann.

Kostenlose Demoversionen

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Peak Performance for an Electric Vehicle

By Benjamin Ahrenholz, Head of CAE Department, Volkswagen Motorsport GmbH, Hannover, Germany

Developing a vehicle to compete in the Pikes Peak International Hill Climb is a daunting test for engineers around the world. Volkswagen Motorsport engineers were determined to build a car that could compete with the best, but they had less than a year to produce, test and race an all-new electric car. Using determination, ingenuity and multiphysics simulation, the Volkswagen team smashed not just the electric vehicle record but the all-time record for all cars, including those powered by internal combustion engines.

"Who could design an electric-powered car from scratch in nine months?"

If there is one message to take away from Volkswagen Motorsport’s stunning electric vehicle performance in the 2018 Pikes Peak International Hill Climb, it is that things do not always work out as planned. Sometimes they work out better.

The plan — launched only nine months before the 96th running of the renowned race on June 24, 2018 — was to beat the all-time electric vehicle (EV) record this year, and then improve the design and try to break the overall record established by an internal combustion automobile next year. Instead, race car driver Romain Dumas negotiated the 156 sharp bends on the 12.42-mile course in the Volkswagen I.D. R Pikes Peak car in less than 8 minutes at 7:57:148, smashing not only the electric vehicle record by more than a minute but also the overall record by over 16 seconds.

This successful result in such a short development time was due to the hard work of a team of Volkswagen employees across the company, along with some help from Ansys, who consulted with Volkswagen on the design and validation of the battery pack that powered the car to victory.

GOING ELECTRIC

When VW officials decided in 2017 that their longterm strategy would focus on building and selling EVs as passenger cars, they wanted to make a bold demonstration of this commitment — and soon. Not in 2025 or even 2020, but in 2018. Searching for a place to make this statement, they noticed that the 2018 Pikes Peak International Hill Climb, which finishes at an altitude of 14,115 feet, was scheduled for the following June — a tight squeeze. Who could design an electric-powered car from scratch in nine months? The motorsports team is used to changing car designs from week to week, so the task fell to VW Motorsport.

By deciding to employ an existing race car monocoque, the Norma M20 created by Norma Auto Concept in France, the team eliminated the need to design the body of the car. But the monocoque, which typically houses an internal combustion engine, had limited space available for batteries, even when the engine was removed. And Volkswagen Motorsport had little experience designing batteries. When the Ansys team offered to help design and validate the battery modules using simulation, Volkswagen accepted.

THE CHALLENGES OF BATTERY DESIGN

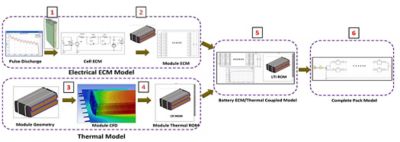

Six-step simulation process schematic

Primarily, the battery modules had to store enough energy to reach the peak speed that Dumas would need to drive on the course’s straightaways, while ensuring that there would still be energy left at the end of the race. Running out of power short of the finish line would not do. Solving this challenge involved issues of cell selection, sizing of the battery pack, cooling of the pack and charging efficiency, among others.

Optimizing these parameters was key to success. The battery packs had to fit the space available in the chassis while providing sufficient power. Adding more battery modules than necessary would increase the vehicle’s weight and slow it down. Battery temperature would affect the amount of energy available — the state of charge (SoC) — so determining if air cooling, water cooling or no cooling at all was needed was important. Charging efficiency was critical because the rules of the race stated that if a run was interrupted for any reason, such as wildlife crossing the road, the team had to start over and be ready to go again in 20 minutes.

A SIX-STEP SIMULATION APPROACH

Using Ansys Twin Builder, the Volkswagen Motorsport and Ansys teams conducted a six-step multiphysics simulation involving electrical and thermal parameters to design and validate the battery model. The first step was to develop an equivalent circuit model (ECM) for a single battery cell. The ECM simplifies a complex circuit to aid analysis.

Engineers used test data from a pulse discharge to get all the parameters needed to calibrate the ECM. The first step was done on a single cell to verify that the cell model was created correctly. If anything was wrong, the validation would have revealed the problem. Engineers concluded from step 1 that the ECM is a function of SoC and temperature. The Twin Builder simulation of the ECM was super-fast, requiring only seconds to simulate one full drive cycle of the race car through the entire race course.

Step 2 combined all the ECM cells serially to form an ECM module.

Step 3 involved computational fluid dynamics (CFD) simulation of the thermal properties of a battery module using Ansys Fluent. Running a CFD simulation was necessary because the electrical performance of a battery is a function of temperature, and a thermal model is needed along with the ECM to predict battery temperature.

The twin builder simulation of the ECM was super fast.

The simulation model for a full CFD analysis of a battery model is typically extremely large. In this case, after importing the geometry of the proposed battery module and housing and performing the meshing process, the engineers had a mesh containing 67 million cells. With so many calculations to perform, it took approximately 48 hours using 100 CPUs to run a thermal simulation of one full drive cycle.

This presented a new challenge because, eventually, the ECM and the thermal model would have to be run together in a two-way coupled multiphysics simulation, the discrepancy between the few seconds it took to run the ECM simulation on one CPU and the 48 hours to run the thermal simulation on 100 CPUs made it impossible to couple these simulations.

The solution came in step 4. Using Fluent, the engineers extracted key thermal characteristics of the system to create a reduced order model (ROM) for the thermal simulation. The ROM is linear and time invariant (LTI), and orders of magnitude smaller than the full CFD model. It yields results that correlate well with the full CFD model, but it runs 10,000 times faster.

Solving the battery challenge virtually through simulation instead of building a series of physical prototypes helped them accomplish their goal in the short time frame they were given.

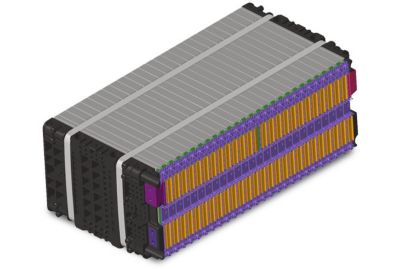

Geometry of a battery module

In step 5, the ECM and the thermal LTI ROM models were used together to run a two-way coupled multiphysics simulation in Twin Builder. The ECM predicts the electrical performance and how much heat is created. The LTI ROM thermal model takes this heat generation value and predicts temperature, then the temperature is transferred back to the ECM model to determine its effect on electrical performance. This cyclical iteration process continues until the simulation converges on a solution.

Step 6 involves putting the individual battery modules into the full 10-module battery pack that will power the whole EV. Volkswagen used a third-party simulation tool for this final system-level step. The complete battery model predicts the voltage and current relationship to ensure that the battery has sufficient energy for the task at hand — in this case, enough charge to finish the race. It also helps to predict the peak power output of the battery system, and therefore the top speed that the race car can go. Step 6 also predicts battery temperature, making sure the peak temperature is not exceeding the limit.

The result of the complete simulation process was to give Volkswagen Motorsport engineers confidence that the battery pack had enough charge to get them to the finish line, and that thermal properties were not a concern in this short race. Solving the battery challenge virtually through simulation instead of building a series of physical prototypes helped them accomplish their goal in the short time frame they were given.

Watching a live stream of the race from their offices in Hannover, the Volkswagen team cheered Dumas and the I.D. R Pikes Peak race car as they climbed the mountain, and they erupted in celebration when the car crossed the finish line in record time. But some of them were not entirely surprised by the result. From practice runs in a driving simulator, the mean time for finishing the race was around 7:57, with a possible faster finish if everything went perfectly and a slower one if they ran into difficulties. Dumas brought the car home in 7:57 — right on the button.

LOOKING AHEAD

Having accomplished two years’ worth of goals in the first year, Volkswagen was momentarily at a loss as to how to proceed — a great problem for an engineer to have. Should they go back to Pikes Peak to try to improve on their record next year, try to break the record in another race, or switch their focus to the consumer line of I.D. cars that they hope to be selling to the public within a few years?

Whatever they decide, Ansys engineers are happy to have played a role in Volkswagen Motorsport’s outstanding 2018 Pikes Peak victory, and stand ready with their suite of Ansys simulation solutions to help them solve the challenges ahead.