ANSYS BLOG

August 19, 2021

Create Powerful Electronics Reliability Simulations with New Ansys Product Integrations

Predicting printed circuit board (PCB) reliability has become increasingly important due to demands placed on state-of-the-art electronic systems. Reducing costs and time-to-market has made it imperative that companies use simulation to reduce design spins and physical tests. It is vital that engineers look to simulation earlier in the design process to make the best decisions possible, which will result in products that meet or exceed their reliability goals. The latest updates in Ansys Sherlock and electronics reliability in Ansys 2021 R2 help users deliver on their product development goals.

Rapid Model Creation for Drop-Test Studies and Other Workflows

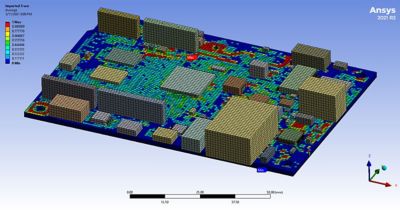

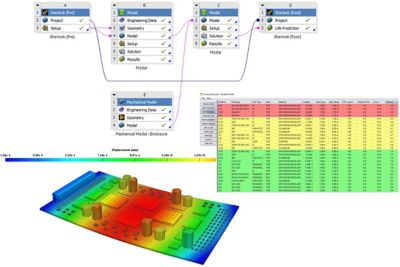

Perhaps the most significant update in Sherlock for Ansys 2021 R2 is the semi-automated model generation workflow for Ansys Workbench LS-DYNA drop test simulations and other mechanical simulations. As part of this workflow, Sherlock now supports the export of high-fidelity, fully meshed PCB models to Ansys Workbench using special modeling paradigms that are helpful for drop test and other analyses.

When using the new workflow, users can choose to export to the CDB format (mesh format) while taking advantage of a new shell-and-beam approach to create beam elements that represent ball grid array (BGA) package solder balls. In the export process, Sherlock opens a new Workbench project, imports the CDB file (as an external model), and connects it to an Ansys Mechanical model system. From there, the process continues with the automatic launching of Mechanical to facilitate the (automatic) creation of contacts and other features. In cases where an ODB++ file was used to create the PCB model in Sherlock, this process also includes automatic trace mapping of the PCB in the Mechanical interface.

This new workflow greatly reduces the time spent performing meshing, contact generation, trace mapping and other modeling processes. Further, the new shell-and-beam approach for modeling BGA solder balls increases computational efficiency when performing drop-test simulations, among others.

Figure 1: Rapid model creation using a novel solution available through Ansys Sherlock and Workbench/Mechanical.

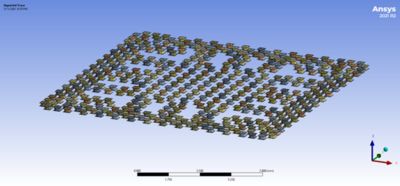

LS-DYNA users can explore the new multi-scale, co-simulation process that enables faster simulations to provide additional insights into details that are often not captured using traditional modeling strategies.

Essentially, this approach facilitates a two-way sub-modeling approach to include the effects of additional modeling details. For example, imagine running a drop-test simulation of a smartphone with one or more BGA packages mounted on a PCB. In a global model, the solder may be represented using beams, enabling the simulation to run more efficiently. However, at the same time, a detailed representation of the solder can be captured in a separate model. Through a co-simulation process, these two models pass data back and forth to one another (taking advantage of parallel processing, as well) during the simulation of the drop event, thus providing a high degree of accuracy and efficiency.

Figure 2: Representation of a co-simulation process where two models pass data back and forth during the simulation of a drop event.

Expanding the Integration Between Workbench and Sherlock

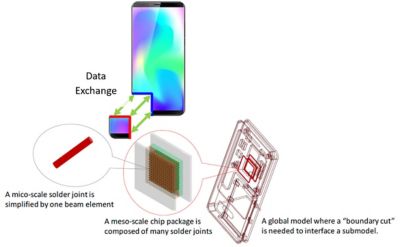

In Ansys 2021 R1, we established a Sherlock plugin for Workbench that enables users to connect Sherlock projects to Mechanical analysis systems (such as Modal, Harmonic, etc.), run these simulations and evaluate reliability results (via the Sherlock Results and 3D Viewers) without needing to go back to Sherlock. In Ansys 2021 R2, we extended this functionality by enabling users to start in Workbench by opening a new (empty) Sherlock project rather than needing to import an existing project.

In addition, we enabled the ability to connect PCB models generated from Sherlock with their associated enclosures/housings, simulate the resulting assembly under a variety of conditions and review the PCB reliability results without having to go back to Sherlock (via the Sherlock results and 3D viewers). The expanded workflows are ideal for Sherlock users who want to go further in assessing their designs in Mechanical, as well as Mechanical users who want to build PCB models rapidly and efficiently in Sherlock and then assemble and evaluate them along with other mechanical structures.

Figure 3: Expanded Sherlock plug-ins in Ansys Workbench allows for increased Mechanical analysis.

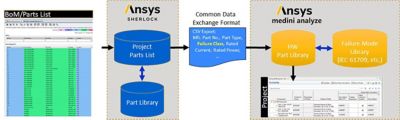

Connecting Sherlock With Ansys medini analyze

Sherlock is the leading reliability physics analysis (RPA) tool for electronics reliability assessments related to thermal cycling, mechanical shock and vibration, and other conditions. Ansys medinianalyze is a leading tool for functional safety and reliability engineering, streamlining functional safety analysis across the entire system architecture — including electronics down to the chip level.

In Ansys 2021 R2, Sherlock users can export parts lists with failure class information that is used to select handbook failure rate data within medini analyze. Once this data has been assigned, a variety of assessments can be performed to ensure compliance with safety standards/industry guidelines, specifically ISO 26262, IEC 61508, ARP 4761, ISO 21448 or MIL-STD-882E.

Figure 3: Workflow integration process between Ansys Sherlock and Ansys medini analyze.

This is an especially useful connection for users because products can be analyzed consistently using system safety and reliability techniques such as FMEDA/FMECA, FTA, RBD and so on. With this connection, users will have improved confidence in their product meeting safety and reliability standards.

For Ansys 2021 R2, we also worked on a number of additional enhancements that will benefit users. Some highlights include:

- Sherlock theory guides provide additional background on how Sherlock is performing solder fatigue, random vibration and other simulations, and addresses how reliability metrics (time-to-failure, etc.) are calculated.

- Improved harmonic vibration reliability predictions based on the contribution of responses at multiple frequencies.

- Thermal-Mech now uses the Mechanical APDL solver for improved performance.

Learn More About Sherlock Updates in Ansys 2021 R2

If you are interested in learning more about our electronics reliability updates, attend the Ansys 2021 R2 What’s New in Electronics Reliability webinar presented by the Ansys Sherlock Product Manager, Kelly Morgan. During the webinar, he will discuss the electronics reliability/Sherlock updates in Ansys 2021 R2 in detail and deliver new feature demonstrations.

Current Ansys Sherlock customers with Ansys Learning Hub licenses can access our newly revamped Electronics Reliability page. This page includes tutorials, a user forum to ask questions to our experts, advanced training and more.

To stay up to date on the latest electronics reliability webinars and capabilities, follow us on our Ansys Structures LinkedIn Channel.