规格速览

利用Ansys CFX获得行业领先的精度。该工具可快速解决旋转机械问题,使工程师能有更多时间专注于其设计。

CFX以其极高的鲁棒性而著称,是旋转机械应用方面的黄金标准CFD软件。求解器和模型都封装在一个现代化、直观而灵活的GUI中,具有使用会话文件、脚本和强大的表达式语言进行定制和自动化的广泛功能。高度可扩展的高性能计算将有助于加快包括泵、风扇、压缩机和涡轮等产品的仿真速度。

利用Ansys CFX获得行业领先的精度。该工具可快速解决旋转机械问题,使工程师能有更多时间专注于其设计。

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

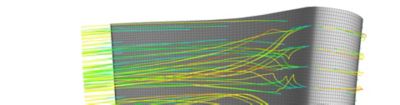

Ansys CFX让工程师能够研究新的复杂旋转叶片几何结构的热性能。

“在这种应用中尝试的其他代码,通常不会在这种节点间距[0.001mm]处收敛。研究人员针对由平面射流冲击平板构成的测试问题验证了CFD结果,并获得了非常好的相关性。”

新的制造方法已经为更有效的旋转冷却通道几何结构打开了大门。新的几何结构将带来更好的性能和效率,但更加复杂。为了获得高度精确的结果,普渡大学的工程师团队选择采用Ansys CFX。

工程师在很短的时间内完成关键计算。有了额外的时间,他们可以进行更深入的比较,并运行进一步的仿真,以全面优化其产品。Ansys CFX为他们提供了工具,使他们找到多网格“编织”设计。新的旋转设计采用更冷的叶片运行,并已在美国空军研究实验室实施。

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

2025年7月

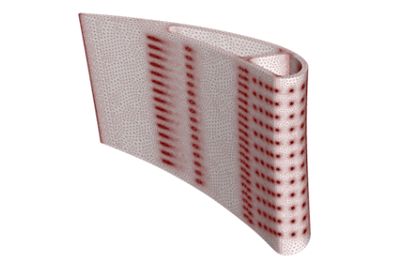

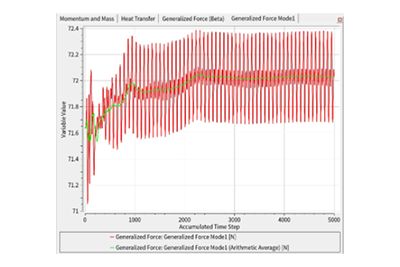

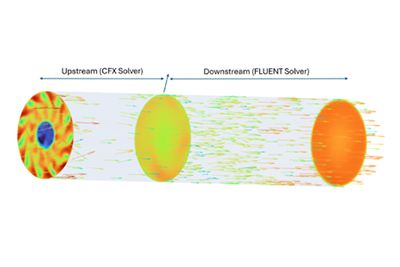

在2025 R2版本中,Ansys CFX软件更新包括混合流体-流体和流体-固体交界面、广义模型力(beta),以及通过系统耦合在流体边界实现CFX与Fluent的耦合。

具有混合流体-流体和流体-固体交界域界面,简化了案例设置。由于流通道网格可以同时连接CHT固体网格(流体-固体)和内部流体网格(流体-流体),因此简化了涡轮叶片CHT设置。

CFX现在包含边界广义力的内置计算功能,使用户能够更好地评估强制响应计算中强制项的收敛性。

通过系统耦合在流动边界处耦合CFX和Fluent。支持在入口、出口和开口边界处进行耦合。有助于将CFX中的涡轮机械组件连接到Fluent中的上游/下游组件。

Ansys CFX功能

Ansys CFX的先进物理模型,可帮助工程师解决旋转机械应用中最复杂的挑战。这款功能强大的软件已经过广泛验证,并以其鲁棒性和准确性而著称。简化的旋转设置过程并集成了叶片设计工具,可确保您有更多时间来优化设计。无论是用于叶片设计优化还是高级材料建模,CFX都是您可以用来节省时间和资金的可靠工具。

以高精度和无法超越的速度解决各种与流体有关的问题

要让包括残障人士在内的所有用户都能访问我们的产品,这一点对于Ansys而言至关重要。因此,我们始终致力于遵循基于美国访问委员会(第508节)、Web内容可访问性指南(WCAG)和当前自愿产品可访问性模板(VPAT)格式的可访问性要求。

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。