构建和验证,部署和扩展混合数字孪生模型

构建、验证、部署和扩展混合数字孪生

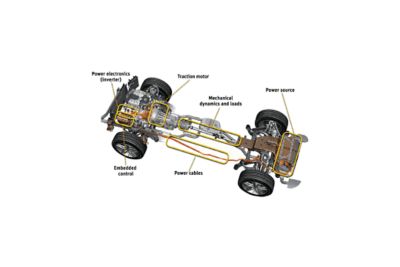

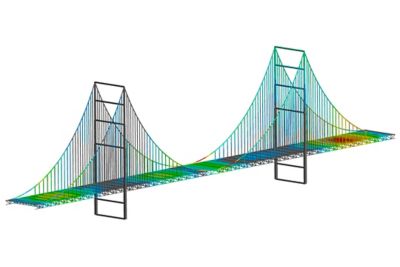

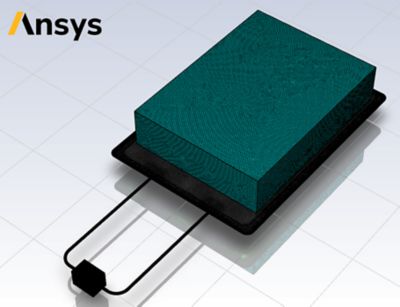

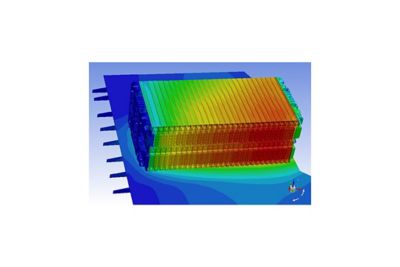

由分析驱动的、基于仿真的数字孪生是运营中真实资产的联网虚拟副本,通过集成多域系统仿真,再现真实资产的生命周期与体验。混合数字孪生不仅能实现系统设计和优化以及预测性维护,还能优化工业资产管理。通过部署Ansys Twin Builder,您可以提高营收、管理底线成本,同时获得并保持竞争优势。

规格速览

Ansys Twin Builder使您能够快速创建数字孪生——运营中真实资产的联网副本。这样可以改善生命周期管理和实现真正的预测性维护,从而节约成本,帮助企业保持竞争优势。

-

构建和验证系统模型和数字孪生 -

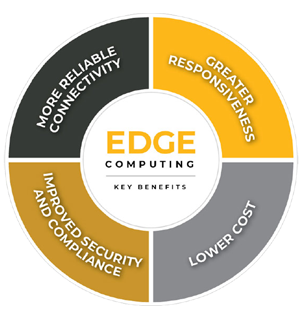

在IIoT平台上部署数字孪生

-

使用IIoT平台轻松扩展部署规模 -

灵活许可

-

混合分析

2025年7月

新功能

探索全新的Ansys数字孪生功能,包括混合分析、更快的ROM、改进的部署以及增强的求解器工具,以实现更智能、更快速的仿真。

利用混合分析释放数字孪生的潜力

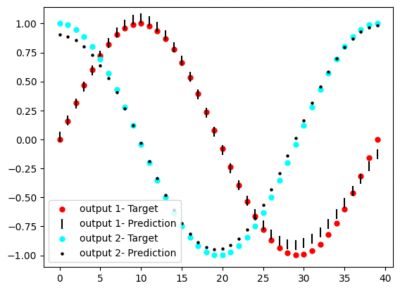

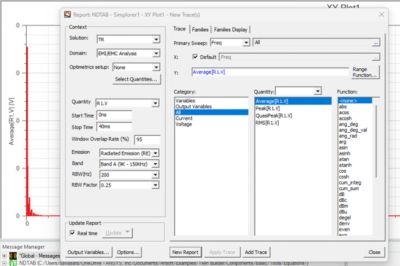

了解Ansys数字孪生的关键更新:用于融合的多输出高斯过程、用于标定与融合的增强型绘图功能,以及用于简化数字孪生部署和交互的全新Web应用。

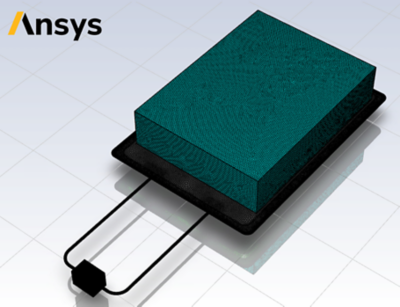

ROM创建的自动化、速度和准确性

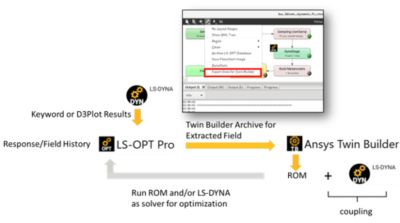

通过新的参数化动态ROM、高级SVD对角化选项和改进的LS-OPT/Twins工作流程来增强ROM创建过程,实现了更高的速度、自动化水平和精度。

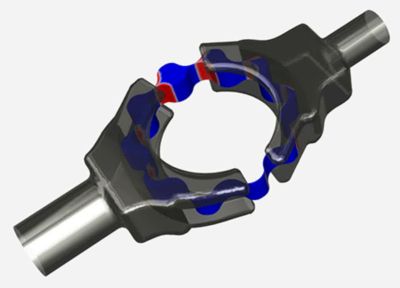

增强型求解器、模型库和用户体验

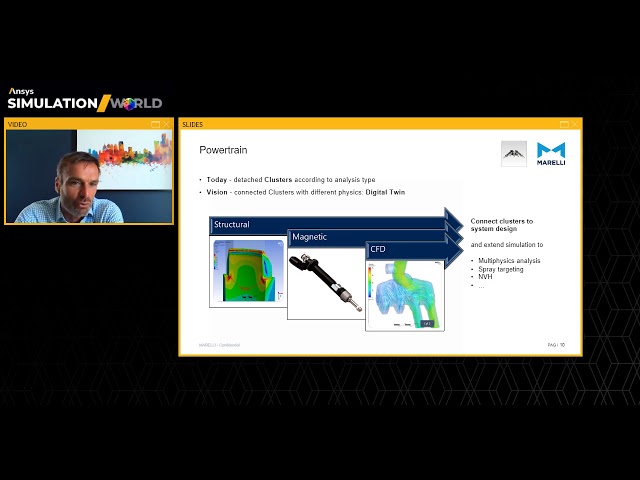

电机设计工作流程受益于关键的改进功能,包括Motor Equivalent Circuit Toolkit的增强功能和MotorCAD中改进的热降阶模型(ROM),以实现更快、更准确的系统级热预测。

案例研究

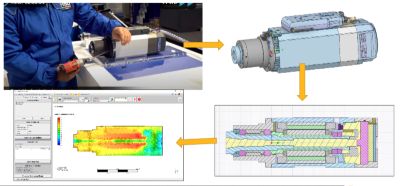

Ansys Twin Builder创建了运营中真实资产的联网虚拟副本

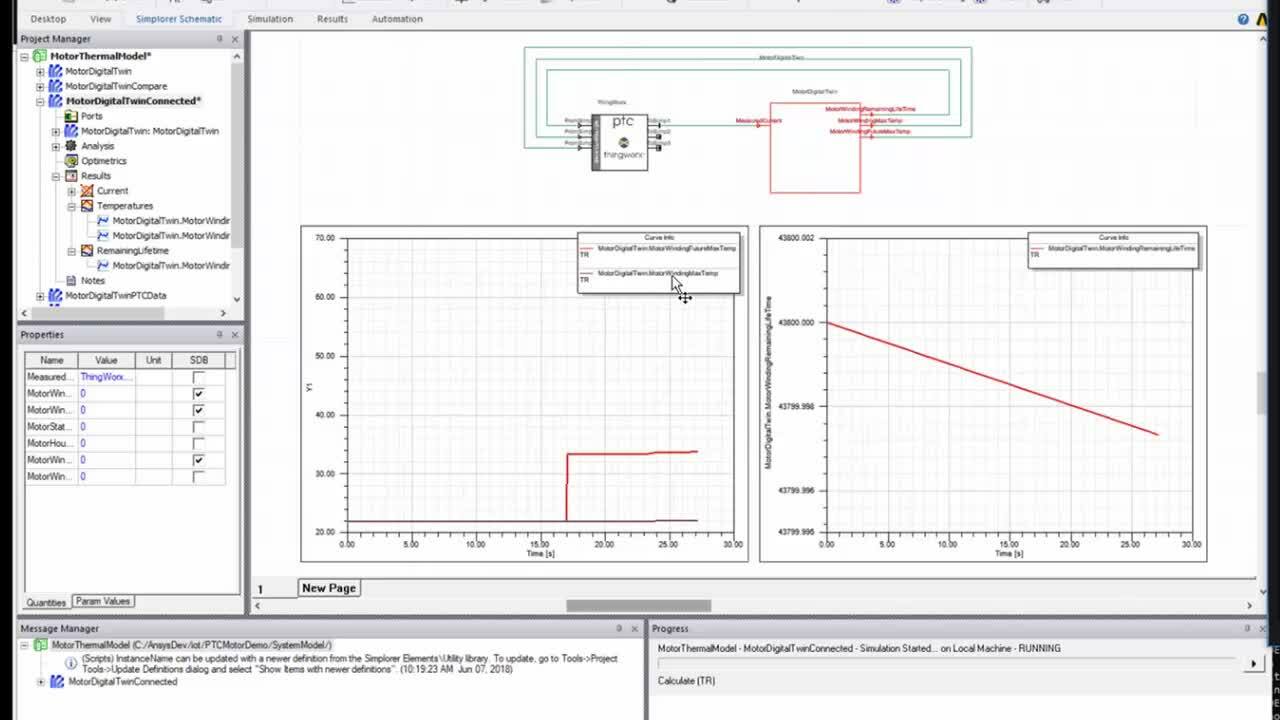

Ansys Twin Builder是一款独特的开放式解决方案,允许工程师创建运营中真实资产的数字孪生联网虚拟副本。数字孪生能够实现真正的预测性维护,从而节省成本,并主动优化资产运营。Ansys Twin Builder可以让您构建、验证和部署数字孪生,有可能将创建准确产品模型所需的时间减少一半。一旦完成部署,用户预计可将产品性能提高25%,并在产品的生命周期内节省高达20%的维护成本。

主要特性

Ansys Twin Builder提供多种功能,可用于对运营中的资产进行建模和仿真。

- 多域系统建模器

- 广泛的0D专用库

- 第三方工具集成

- 降阶模型(ROM)

- 嵌入式软件集成

- 集成后处理功能的多域系统求解器

- 快速HMI原型设计

- 系统优化工具

- XIL集成

- IIoT连接与孪生确认和验证(V&V)

- Twin Deployer

- 混合分析

- 从Twin Deployer导出Web应用

Twin Builder资源与活动

专题活动和网络研讨会

Webinar Series

数字孪生网络研讨会系列

构建、验证和部署基于仿真的数字孪生

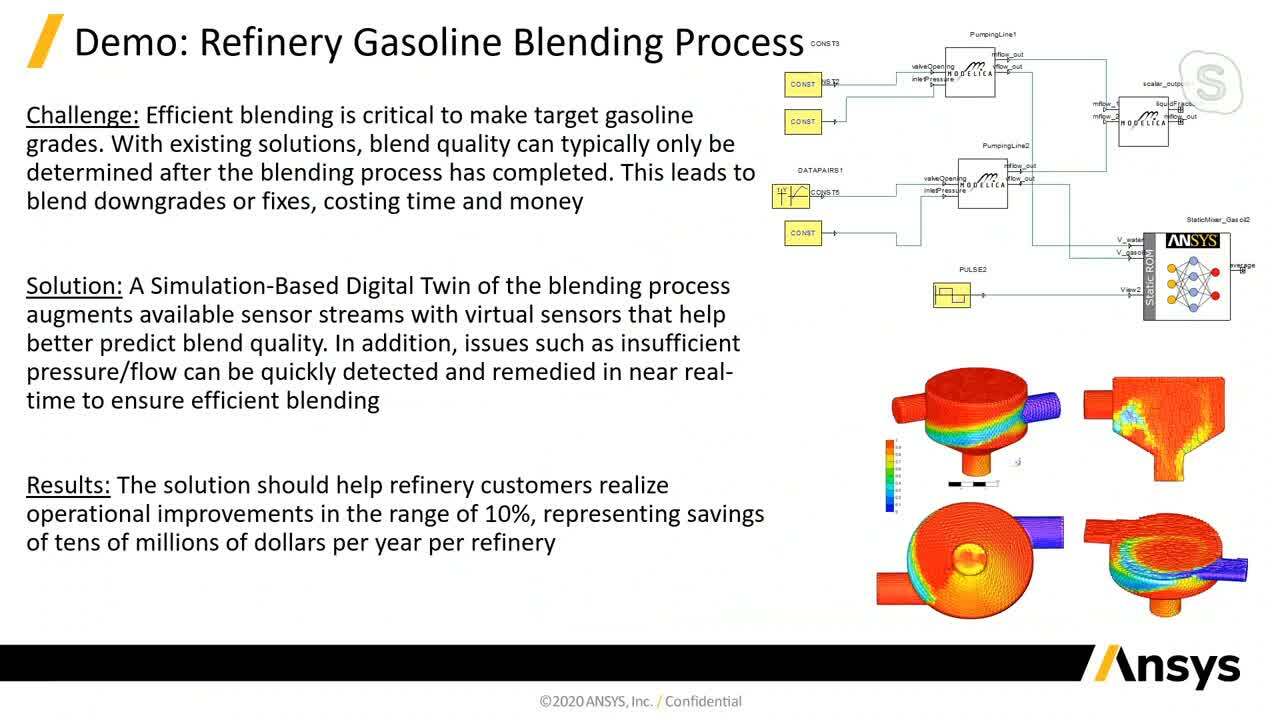

在60分钟的研讨会中,我们的专家将演示Ansys Twin Builder在各行业和应用中构建、验证和部署基于仿真的数字孪生的强大功能。

On Demand Webinar

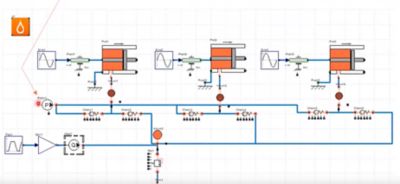

利用Twin Builder流体动力库的强大功能快速构建系统模型和数字孪生

欢迎了解Ansys Twin Builder流体动力库,它适用于从钻头和变速箱到汽车悬挂系统和飞机起落架的各种工业应用。

On Demand Webinar

On Demand Webinar

通过使用Ansys Twin Builder的降阶模型增强仿真

作为一款前沿的数字孪生开发平台,Ansys Twin Builder可为创建、部署和管理物理系统的数字孪生提供强大的框架。但是,高保真度仿真的计算需求可能会令人望而却步,因为其通常会耗费大量的时间和资源。

On Demand Webinar

案例研究

点播网络研讨会

Ansys软件可轻松访问

要让包括残障人士在内的所有用户都能访问我们的产品,这一点对于Ansys而言至关重要。因此,我们始终致力于遵循基于美国访问委员会(第508节)、Web内容可访问性指南(WCAG)和当前自愿产品可访问性模板(VPAT)格式的可访问性要求。

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。