ANSYS ADVANTAGE MAGAZINE

May 2022

Wind energy is one of the world’s most promising sources of renewable energy. Interest in this emission-free natural resource has grown even more as concerns over air quality and climate change continue to rise globally.

As demand for wind energy increases, the need to advance technology to produce larger, quieter, and less expensive wind turbines also intensifies. As engineers work to make these improvements, they must also ensure the safety of components like the improved blades by verifying their structural integrity and fatigue resistance.

The 28 engineers at Bewind GmbH, a German systems design and engineering firm, have more than 400 total years of wind industry experience. They use PyAnsys to optimize the fatigue assessment of their wind turbine blades.

PyAnsys is a suite of open source software that allows you to interact with several Ansys solvers at once within the Python ecosystem, using a programmable interface. This means you can create specialized solutions in Python while integrating Ansys’ structural, electromagnetic, and composites simulation solvers (among others), along with other computer-aided engineering (CAE) applications and tools.

The Bewind engineering team uses PyAnsys to create a customized, automated workflow for a more effective and accurate fatigue assessment of their wind turbine blades. This tailored automation saves significantly on time and costs by using the predictive accuracy of Ansys solvers to validate that the blades are both structurally sound and operationally efficient.

Take an Aerodynamic Load off with PyAnsys

High-pressure aerodynamic loads are applied to wind turbines to drive rotor blades with enough force to generate mechanical power and, ultimately, electricity. Naturally, this causes vibration during operation. This vibration, coupled with the number of applied loads or stresses, can lead to a host of problems, including crack propagation, delamination, and fatigue phenomena.

Typically, rotor blades are designed with this potential fatigue in mind, yet fatigue loads remain one of the largest contributors to blade damage. Delamination of the composite layers of the blades is the most common cause of total blade failure.

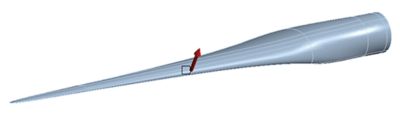

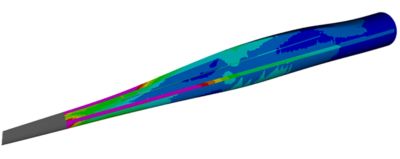

Mechanical model (top) and plot visualization of a turbine blade

When materials experience fatigue, small cracks initiate and grow under the influence of cyclic loading. Even though the applied load is less than the tensile strength of the material, the repeated, cyclic nature of the loading can cause fracture and failure. Fatigue loads come in two categories: constant and variable amplitude. In real-world scenarios, variable amplitude cyclic loading is more common.

However, because the load’s amplitude fluctuates over time, more computer processing is required to simulate damage to the material. The load-time history of parameters such as force, torque, stress, and strain can be used to calculate fatigue cycles. Additional methods can be used to summarize irregular and extended load histories, like the rainflow-counting algorithm. This method is often used to analyze and calculate loading cycles for various amplitudes and then extract a damage parameter using Miner’s Rule, one of the most widely used cumulative damage models for fatigue failures. Miner’s Rule assumes that the damage done by each stress cycle at any given stress level is equal, which means that the first stress cycle is as damaging as the last.

As you may expect, the computational effort of such algorithms for an entire rotor blade is time-consuming and expensive.

The engineers at Bewind reduce the computational workload by using PyAnsys with open-source, just-in-time (JIT) compilers and parallelization frameworks. These hardware solutions combine with Ansys simulations and other models within Python to accelerate and automate the calculations. The combination of Python with a high-level programming language and JIT compilers generates fast machine code. This enables Bewind engineers to develop state-of-the-art workflows in less time to get the maximum performance out of their workstations. Nowadays, they can analyze all composite layers of an entire rotor blade based on stress time histories in only two days on an HP Z4 computer with 12 threads. Previous workflows took about a week and could only take the top and bottom strain of an element into account.

Additionally, with PyAnsys you can manipulate your simulations to explore even more possibilities in shorter amounts of time. For example, Bewind engineers implemented the invariant-sector method, which accelerates fatigue assessment even more for composite materials. This innovative approach, which relies on a precise selection of areas — or sectors — to evaluate, provides the same level of accuracy as other methods with significantly less computational effort. Fortunately, composite materials show favorable fatigue behavior, so even a slight reduction in exposure to fatigue stress can increase fatigue life. This extended life cycle reduces costs by leveling energy costs over a longer span of time. However, these savings are insubstantial compared to the long-term cost efficiency of ensuring blade reliability by improving fatigue assessment.

Easy as PyAnsys

By integrating Ansys products into a Python environment, Bewind engineers can customize their fatigue assessment workflow to include standard post-processing tasks and fatigue post-processing of composites. This tailored workflow is achieved by combining packages within the PyAnsys family, Python scripting capabilities, and the customization functionalities of Ansys Composite PrepPost (ACP). This well-crafted approach not only accelerates Bewind’s assessment time, but also expands modeling possibilities.

PyAnsys currently includes packages that interface with Ansys Mechanical APDL (MAPDL), a multiphysics simulation and equation solver; Ansys Data Processing Framework (Ansys DPF), a scalable data processing system; and the Ansys Electronics Desktop (AEDT), which includes multiple electronics simulation products to create designs, virtually verify design performance, and implement these designs in large-scale system-level simulations.

PyAnsys offers two options for post-processing within Ansys DPF: PyDPF-Post, which plots data in Ansys binary result files, and PyDPF-Core, which allows you to manipulate your result files and create new data. Further, PyDPF-Core streamlines and simplifies scripting by letting you chain, or consolidate, operators and functionalities for a more seamless processing flow. With PyMAPDL, you can create geometry and mesh, plus set up your model. Through PyAEDT, you can simplify scripting for AEDT, which aids in electronics and electromagnetic simulation processing.

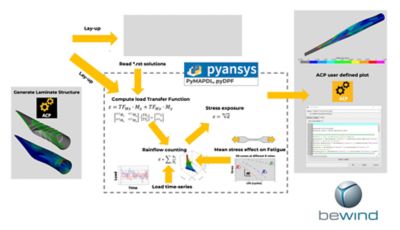

Figure 1. Illustration of Bewind’s integration of PyAnsys with two templated load cases to compute load transfer functions at varying stress levels at each composite layer using the binary result files of a rotor blade model.

In addition to customization, the Bewind team performs advanced analyses for laminated composites, including a successful high-cycle stress-life assessment, which is a post-processing evaluation currently unavailable in standard post-processing software.

As a bonus, Bewind engineers can now access and use Ansys software easily through a standalone native CPython framework outside of Ansys Workbench. The team can select Ansys software from their in-house ecosystem as a regular Python package and combine it with thousands of other available open-source packages within Python. Adding another layer of ease, PyAnsys speaks the language of today’s software developers and users. CPython is the most widely used implementation of the Python language written in Python and C, which blends Python’s object-oriented nature and ease of use with C’s procedural programming style.

How Bewind Saves Time

From multiple Ansys tools at their fingertips to manageable interfaces just clicks away in Python, PyAnsys enables the Bewind engineering team to develop sharper, more compact workflows with less programming effort. Unnecessary read-and-write routines are also minimized, including entering input and output files onto hard disks.

As illustrated in the workflow diagram in Figure 1, Bewind is able to integrate PyAnsys with two templated load cases to compute load transfer functions for stress levels at each composite layer using the result files of rotor blade model simulations.

There are two types of loads to consider when assessing wind turbine fatigue: aerodynamic loads such as shear, drag, and lift in the flapwise, or thrust direction; and inertial loads like gravity or blade dynamics in the lead-lag, or dragging direction. Generally, the flapwise direction is where most loading occurs. Still, both types of loads are leading causes of fatigue because they occur in cyclical, orthogonal bending directions, which create perpendicular intersects that add stress to the blades. In addition, both types of loads have large amplitude and mean value variations, which means there is more load fluctuation to cause fatigue.

As shown in Figure 1, the load transfer function is applied to the load time-series to evaluate the stress time-series in the model. And at Bewind, every load time-series evaluation used in any model is the careful result of hundreds of multibody simulations of the entire wind turbine. Next, each fatigue scenario is identified through a rainflow-counting algorithm accounted for during the design assessment. Following this step, the team uses S-N curves — or stress-life curves — at varying applied load amplitude levels and mean load levels to demonstrate the mean stress effects in a Goodman diagram model. This helps to illustrate the evaluated composite materials and enables the team to determine the amount of damage in each fatigue scenario.

As a final step, the engineers can engage ACP to examine and visualize the overall damage in the laminate via user-defined plots.

Lighten Your Load, Have a Slice of PyAnsys

Together with customization, one of the top benefits of working in a Python environment is the access to robust, plentiful Python libraries. You also have access to PyAnsys-specific subroutines supported by efficient and powerful data analytics algorithms to assist with complex studies.

Like Bewind, engineering teams worldwide can use PyAnsys to customize their workflows, accelerate calculations, automate tasks and design processes, power applications, fuel innovation, and more.

With an inventive Python community at hand, an easy-to-use programming language that encourages reuse, and Ansys’ leading simulation solutions, PyAnsys delivers nearly endless creative and computational possibilities. To learn more, visit the PyAnsys page on GitHub here: github.com/pyansys.

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。