ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Change Managed

Ansys

After GE Power’s acquisition of Alstom, Sigurd Kubel took the reins of a massive software conversion. This “switch” required integrating GE’s simulation-based workflow into Alstom’s best-practice production processes. Without interrupting steam turbine development, Kubel’s team — aided by its expert partners — retrained 80 engineers and service analysts, and successfully implemented the workflow.

Change can be horribly disruptive or powerfully constructive: It depends on how it’s managed and received.

Poised to tackle change with a capital “C,” lead engineer Sigurd Kubel understood this all too well. He had been charged with a critical software conversion and the subsequent retraining of 80 Alstom steam turbine engineers and analysts. They and he had come to GE Power after GE’s 2015 acquisition of Alstom’s power and grid businesses. Together, they were to deliver on daily production goals while adapting to an unfamiliar workflow with new simulation software.

"In the simplest terms," says Kubel, "replacing one simulation workflow with another is a bit like switching email providers. At the end of the day, you’ll be able to send and receive emails, but you’ll have to figure out the functionality, learn and integrate the new features, customize your settings, etc."

This analogy falls apart, of course, when dealing with power equipment, where the margin for error is slim at best. Failure to perform an accurate analysis of a turbine exposed to temperatures of up to 620 C can severely compromise plant safety. Crafting a successfully delivered email does not involve meeting strict quality control measures, nor does it necessitate years of best-practice experience.

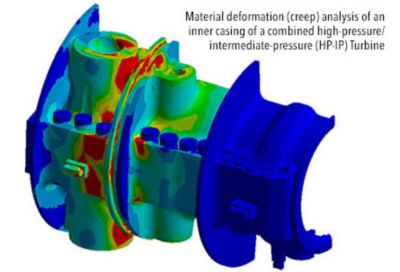

GE Power has long employed finite element analysis (FEA) simulation to predict how its turbines and other power plant machinery will behave under variable operating conditions. "Making these predictions accurately is becoming more critical due to greater fluctuation in the electric grid," says Kubel. "Renewable energies like solar and wind, which are harder to align with consumption, have made plant operations more cyclic to balance out the fluctuation. Machines that once operated under relatively constant conditions are now subjected to many more starts, stops and load changes. Without FEA simulation, we would be guessing at safety thresholds and inspection schedules, and unable to demonstrate to customers that we have met their requirements."

After the acquisition, Kubel and his team had to determine which option was optimal: continuing with Alstom’s familiar FEA workflow or transitioning to GE’s. A key consideration was his engineers’ considerable experience with the commercial code favored by Alstom. Moving to GE’s Ansys-engineered workflow, however, promised many more potential benefits. Cost and efficiency savings could be gained through greater collaboration and sharing of models and analyses. Software maintenance would also be more time-efficient. With each new release, GE Power would only have to test, install and roll out one set of updates.

Asked how the one-code decision was received by would-be users, Kubel says: “No matter how experienced you are in your field, at first you are going to feel like a beginner, like you are back in school. In a new programming environment, things are not going to work the way you expect them to work. You must be flexible and adapt, so it is natural that we would hear some less-than-enthusiastic voices. In informatics, there’s a well-known sentiment: You never change a running system.” In other words: If it isn’t broken, don’t fix it.

For most, however, tackling the switch was a welcomed skill-building opportunity. The transition was viewed as more than an even exchange: It was an opportunity for process improvement.

Without interrupting steam turbine development, Kubel’s team retrained 80 engineers and service analysts, and successfully implemented the new workflow.

"In a transition like ours, you cannot move forward by simply repeating an old process with a new tool."

Executing the Switch

Once the decision was made, Kubel’s team inventoried the many FEA-related steps within the analysis workflow. These included steps where FEA was integrated and where there was an integration or exchange with other (often in-house) codes. There were also features such as in-house material laws (e.g., routines that calculated convection based on local condensation) that had to be incorporated.

The team assigned each prioritized step to a small working group composed of GE and former Alstom engineers, plus members from the Ansys ACE team (global support experts) and CADFEM (an Ansys elite channel partner).

"In a transition like ours, you cannot move forward by simply repeating an old process with a new tool," says Kubel. "We communicated what we wanted to accomplish, then let our Ansys colleagues show us the best way to do it. This was an extremely positive and productive way of working."

Kubel estimates that 90% of the overall effort involved demonstrating that the new simulation results matched the old-code results. "When you are dealing with very large models and solving them," says Kubel, "you always find small differences that have to be either explained or mitigated. This validation process is a valuable refinement exercise, which offers hands-on user learning over many improvement iterations."

Before any of the new code could be put into production, local regulators and in-house reviewers had to approve the results. And, for customer-specific requests, "We had to demonstrate that our machines, according to our best knowledge and our best simulations, would fulfill our customers’ operational and efficiency requirements," says Kubel.

The software rollout occurred in stages, as steam turbine development continued uninterrupted. Throughout much of the conversion, there were teams running the new code and others operating with the old.

All received extensive training. Experts in Ansys structural software led week-long, on-site sessions for both the product development and the service teams. Learning continued online with webinars, topical videos, self-paced modules and downloadable resources available on the Ansys-supported, GE Power–dedicated portal.

According to Kubel, there are two keys to summiting an exceptionally steep learning curve. The first is direct access to great customer support. “Using new software with an unfamiliar user interface, we naturally had a lot of ‘beginner’ questions … questions we were a little uncomfortable asking in a formal way,” he says. “Instead of having to file an online support ticket or search an hour for an answer, we were able to pick up the phone and have questions like "Where is that button that you showed me during training?’ answered in half a minute. The technical resources provided by Ansys proved invaluable."

The second is ample training time. "You can’t skimp on training," says Kubel. "You need to set aside a week or two for uninterrupted education. With good trainers and partners, you can accomplish so much more in a concentrated period of time than you could in once- or twice-a-week sessions. The latter is ineffective and, ultimately, more costly."

Unexpected Gains

Ninety-five percent of the proposed three-year conversion was completed in the first 11 months. While management applauded this success, users expressed great satisfaction with the software. They cited its quick calculation times, intuitive interface and powerful capabilities (high-performance computing, parameterization, meshing, geometry editing, etc.). Most of all, they were pleasantly surprised at how quickly they mastered the new functionality.

"You can't skimp on training"

"A huge, greater-than-anticipated gain for us is that we now have this large, in-house community of Ansys software users all over the world," says Kubel. "We can now ask questions and share data in chat rooms — proprietary things that we wouldn’t want to share outside our walls. We also have Ansys representatives or GE personnel conducting web-based meetings and training sessions, to which our whole community is invited. And working in a common software environment allows us to easily import or employ data from other Ansys simulation tools that we use."

Kubel says GE Power is working to meet the challenges of big data storage and leverage digital twin technology to create virtual copies of industrial assets like turbines and power plants. Using operational data, engineers will be able to better predict damage accumulation and schedule maintenance checks in advance of unexpected outages.

"The success of this transition opens up the possibility of combining many more types of physics in our analyses. For example, we can now pair computational fluid dynamics simulation with our mechanical explorations," says Kubel. "This — with the support of our software partner — will allow us to design, manufacture and maintain better products with even greater efficiency."