ANSYS BLOG

June 5, 2019

5 Factors That Define Aerospace and Defense Industry Trends and How to Account for Them

With 97% of aerospace and defense (A&D) executives ready to digitally reinvent their business, according to Accenture, it’s clear that the industry has entered a time of transition.

The A&D industry trends initiating this change are driven by social, political and technological shifts — such as environmental regulations, rising fuel costs and advances in batteries, sensors and connectivity. These shifts are all leading to the development of autonomous, efficient, more electric aircraft.

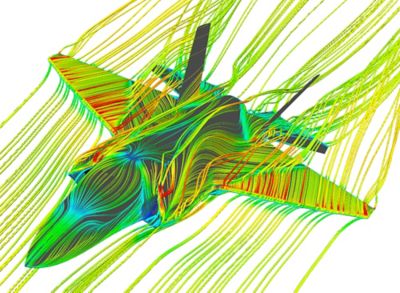

Simulation is the best way to manage and design all the advancements in the A&D industry

As these trends continue to advance aircraft technology, they also increase complexity within the industry. Let’s face it, there are aircraft in service today that are older than the maintenance, repair and operation (MRO) teams working on them. Ensuring that those teams can maintain those legacy designs — and all the new stuff coming off the lot — takes a considerable effort.

In the wake of this complexity, startups are quickly developing methods, products and operations to simplify the A&D industry. As a result, leading A&D corporations must iterate designs as fast as possible regardless of their legacy systems.

One of the fastest ways for A&D startups and leaders to navigate these trends is with simulation technology. With simulation, the A&D industry can quickly iterate designs, ensure product safety, hasten certification and simplify systems.

Simulating Fuel Efficient and Environmentally Friendly Aircraft

Customers and regulators are putting pressure on the A&D industry to produce more fuel-efficient aircraft. This pressure has culminated in new regulations to limit emissions, like carbon dioxide and nitrogen oxides (NOx), and to minimize noise.

However, the A&D industry’s green trend isn’t just about meeting regulation requirements and saving the planet. It could also save significant costs.

Watch how engineers are using ANSYS pervasive engineering simulation to design fuel efficient and environmentally friendly aircraft.

Many A&D companies operate on tight margins that are susceptible to fluctuating fuel costs. Therefore, producing more efficient aircraft makes A&D companies better suited to survive the ebb and flow of fuel costs.

Producing environmentally friendly aircraft can be done in a few ways. Engineers can:

- Use computational fluid dynamics (CFD) to reduce a design’s drag

- Incorporate lightweight materials, like composites, into designs

- Take advantage of optimized topology and lattices with additive manufactured parts

- Improve the materials, control software and designs of propulsion systems

- Design and integrate hybrid and fully electric propulsion systems

All of these methods benefit from the use of Ansys’ pervasive simulation technology. For instance, Ansys CFD can optimize an aircraft’s aerodynamics and improve propulsion systems. Or, Ansys Maxwell can help design new electric propulsion systems. Additionally, Ansys Granta can help engineers find alternative, lighter, high-performance materials among the thousands now available for aviation. Finally, Ansys Mechanical can optimize a part’s topology while Ansys Additive Suite figures out how to print it. In the end, simulation is the key to the fuel efficiency trend in the A&D industry.

Designing Autonomous and Connected Aircraft Requires Simulation

Traffic is a major source of pollution and downtime in megacities. One way to address traffic is to use the space above the streets to move people and packages.

In order to take advantage of this space, the A&D industry is trending toward autonomous vehicles, new cockpit designs and aircraft connectivity.

Watch how engineers are using ANSYS pervasive engineering simulation to design autonomous vehicles, new cockpit designs and aircraft connectivity.

Autonomous aircraft will be able to move people and packages around the city. Much of the research to develop these tools will funnel into sensor, logic and safety systems. Ansys’ pervasive simulation technology can digitally connect, test and validate these systems in a virtual environment. These simulations will speed up development and ensure that autonomous vehicles can handle any weather or emergency situation.

Another A&D industry trend is to take advantage of the thousands of local airports around the United States that are mostly used by hobbyists. By using these airports, airlines can offer local-to-local flights that connect small communities with big cities. To be financially viable, this requires aircraft that are electric or hybrid, and operate with a single pilot. Designing for electrification and these cockpits of the future is a complex task that requires simulation and virtual reality systems so pilots and engineers can test and optimize the aircraft.

Finally, connected aircraft can help the A&D industry entice more people to fly by offering added safety and Wi-Fi features. Free Wi-Fi can be a selling point that gets people off the road and on to a plane. Additionally, the thousands of sensors in the aircraft can use this connectivity to report data back to the airline, improving safety and saving lives. However, adding the antennas that implement this connectivity onto an aircraft isn’t as easy as it sounds. Antennas can affect other transmissions and an aircraft’s aerodynamics. To address these concerns, engineers will need to use simulation technology.

Improving Engineering Productivity in the A&D Industry with Simulation

One of the biggest existential trends affecting the A&D industry is its growing complexity and the strain it puts on engineering productivity.

For instance, it’s possible that a system’s control software could balloon by 21x in about a decade. Keeping track of these changes, let alone the advances in electronics, antennas and sensors, is taxing.

Watch how ANSYS pervasive engineering simulation improves productivity in the A&D industry.

One solution is to train and acquire new technicians, engineers and experts. However, a large number of A&D professionals are retiring before they can train the next generation. Additionally, many veteran and new recruits will have a challenge wrapping their heads around the more advanced technologies — like an autonomous vehicle’s artificial intelligence (AI).

Simulation can help the A&D industry keep up with this trend by automating various functions. This way, engineers can pass on their knowledge and simplify processes so the work of many can be done by one.

For example, a team can take hours to determine the right material for an aerospace part. However, with Ansys Granta, the same research can be done by a single engineer in 20 minutes.

A similar story can be told about Ansys SCADE. It could take a dozen programmers months, even years, to create certification-ready control code. SCADE can produce that same code automatically, cutting the time and cost of the project.

Engineers can also capture and reuse information discovered through Ansys’ multiphysics simulation platform. The process involves running a simulation, creating metadata and reusing it to template the simulation process.

As the complexity of the A&D industry grows, support services and consultancy will become an important way to ensure that engineers will use the full power of simulation. To that end, the Ansys Learning Hub allows engineers to access hundreds of training materials online.

Optimizing Maintenance, Repair and Overhaul Using Simulation

As previously mentioned, there are aircraft in our fleets older than the MRO crews working on them. However, new model aircrafts continue to join those fleets.

Ensuring that crews know how to work with all of these different aircraft models is one of the reasons that the MRO market is expected to increase by 50% by 2028.

Watch how digital twins, predictive maintenance and ANSYS pervasive engineering simulation improves MRO in the A&D industry.

As this market increases, so will the costs to keep all the aircraft running. Simulation can be an excellent tool to keep these prices down.

For instance, traditional MRO crews schedule an aircraft for maintenance based on use — say every 100 flight hours. However, with simulation data, historical data, digital twins and predictive maintenance, MRO crews can schedule an aircraft for maintenance a few flight hours before it needs to be fixed.

This new maintenance schedule limits the number of times an aircraft in perfect working order is scheduled for maintenance. Additionally, this new schedule can find maintenance issues before they delay or endanger passengers.

Simulation Accelerates Defense Technology

Political uncertainty has become an unfortunate reality — evidenced by increased defense spending around the world.

Another reason why this spending has increased is because governments are facing challenges to rapidly respond to threats by providing the latest defense technologies.

In other words, the defense industry is looking to improve engineering productivity, fuel efficiency, autonomous/connected aircraft, MRO and much more.

Watch how to get the latest technology onto the battlefield on time and on budget using ANSYS pervasive engineering simulation.

Simulation can reduce a lot of the effort, budgets and human power needed to achieve these goals.

For instance, relying on simulation instead of manual testing saves millions of dollars and hundreds of thousands of work hours. These simulations hasten the deployment of lifesaving defense technologies onto the battlefield.

To learn more about how simulation can support these five A&D industry trends, read: the A&D industry simulation solutions page.