ケーススタディ

-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

EMI-EMC(電磁干渉-電磁両立性)という用語は、電子製品がその電磁環境内で意図したとおりに動作する能力を指します。エレクトロニクスおよびパワーエレクトロニクス製品は、EMI-EMC規制に準拠する必要がありますが、これにより、製品が過剰な電磁(EM)ノイズを放出しないことが保証されます。このノイズは、伝導性エミッション(CE)または放射性エミッション(RE)として分類され、一定のしきい値を超えてはなりません。また、製品は、バルク電流注入(BCI)や放射イミュニティ(RI)など、周辺機器からのエミッションの影響を受けないことも求められます。

これまでは、こうした規制を満たすために、設計ガイドライン、テスト、エンジニアリング上の判断に頼るのが通例でした。さらに、EMI-EMC現象を捉えるために、高度なシミュレーション手法(回路シミュレーションなど)を使用することも多くあります。シミュレーションで正確な予測を実現することは容易ではありませんでしたが、Eaton社とAnsysの協業により、両社の強みを活かして最先端のEMI-EMCシミュレーションを推進することで、その機能を大幅に向上させることができました。

課題

複数の電子基板、スイッチングデバイス、筐体、電気機械システムを含む大規模で複雑なシステムのEMI-EMC放射予測は、極めて高度です。主な課題の一部を以下に示します。

- 以下の作業には、多大な手作業が必要です。

- 大きなPCBから特定の対象領域を抽出

- PCBコンポーネント用の多数のポートを作成

- 膨大な数の受動および能動部品のモデルをそれぞれのレイアウト寄生ブロックに接続

- 一部の受動部品、能動部品、カスタム設計部品については、高精度なSPICEモデルが利用できません。これらのモデルが電圧/電流バイアスおよび周波数に依存するため、この課題はさらに困難になります。

- モデルの数値的なサイズと複雑さにより、実行時間が長くなります。

- 複雑なシステムについては、収束と安定性の課題に直面します。

- 複数の電気部品と機械部品を含む大規模システムのサブシステム間の相互作用を捉えるのは容易ではありません。

EV用DC充電器

Xストレージ — エネルギー貯蔵システム

データセンター向けのUPSおよびその他のソリューション

エンジニアリングソリューション

Ansys Electronics Desktop(AEDT)™では、電子機器で一般的に見られるさまざまな要素のEMI-EMCシミュレーションに固有の要件に対応するための複数のシミュレーションツールを使用することができます。こうした要素には、PCBレイアウト、バスバー、ケーブル、筐体、パワーエレクトロニクスデバイスなどがあります。

AEDTは、CE、RE、BCI、およびRIシミュレーションに関連する電磁物理現象を捕捉する際に直面する多様な課題に対処できるように設計された複数のEMソルバーオプションを提供しています。AEDTでは、高精度な数学的サブシステムブロック(複数のツールを使用して生成)を1つのシステムレベルモデルにシームレスに統合することもできます。これにより、Eaton社は精度を損なうことなく、重要な電磁相互作用を捕捉することができます。

Eaton社は、AEDTの自動化スクリプティング機能を活用することで、自社のニーズに合わせて複雑なプロセスを自動化することができます。これにより、最小限の手作業でシミュレーション設定を高速化し、解析スループットを最大限に高めることができます。

Eaton社は、主要なプログラムに最先端のシミュレーション手法の導入を継続する一方で、シミュレーションの効率性とロバスト性をさらに高めるために、Eaton社とAnsysは引き続き協力しています。

ベネフィット

「解析ファースト」は、Eaton社のデジタルトランスフォーメーション戦略における重要な柱であり、AEDTを使用したEMI-EMCシミュレーションは、同社のニッチで最先端の機能ポートフォリオにとって極めて重要な追加要素となっています。高度なEMI-EMCシミュレーション機能を利用する主なメリットは以下のとおりです。

- この高度な機能により、Eaton社は設計サイクルの初期段階でEMI-EMCのリスクを特定できるようになり、設計の反復回数削減のほか、テストサイクル、プロトタイプサイクル、および関連するリードタイムの短縮を図ることができました。

- Eaton社は、シミュレーション機能を最適に活用することで、開発コスト全体を削減するとともに、設計サイクル時間(EMI-EMCの観点から)を標準的な産業手法に比べて大幅に短縮することができます。

- さらに、この解析は、最適なEMI-EMCフィルタの選定、優れたPCBレイアウトの設計、最適な電子製品パッケージの考案に役立ちます。

- 開発コストの削減に加えて、最適な磁界設計により、部品表(BOM)コストも削減することができます。

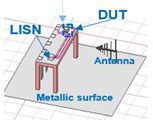

シミュレーション設定 — Ansys HFSS

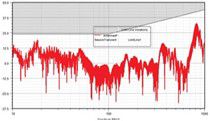

放射ノイズのシミュレート結果と周波数

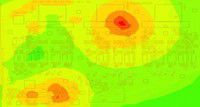

近傍電磁界ノイズのプロット — Ansys SIwaveの結果

さあ、始めましょう

エンジニアリング課題に直面している場合は、当社のチームが支援します。豊富な経験と革新へのコミットメントを持つ当社に、ぜひご連絡ください。協力して、エンジニアリングの障害を成長と成功の機会に変えましょう。ぜひ今すぐお問い合わせください。