-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

米国国防総省が発表した戦略により、デジタルエンジニアリングの採用は防衛業界にとどまらず、他業界にも広がる可能性があります。

防衛業界は、デジタルエンジニアリングがもたらす可能性を的確に示すユースケースを構築するのに最も適した分野であると言えます。現代の防衛システムは極めて複雑です。さまざまなチームが異なるソフトウェアを使用して、コンポーネント、製品、システムの設計および最適化を行っています。こうした要素は、ミッションクリティカルな状況下で完全に相互運用して、国家の安全を支えるために確実に機能する必要があります。米国国防総省は、複雑化する防衛システムを制御する手段として、人、プロセス、テクノロジーを統合するデジタルエンジニアリングの重要性を以前から認識していました。そして今、デジタルエンジニアリングは正式な指針となっています。

2018年には、米国国防総省(DoD)の研究および工学担当の国防次官であるMichael D. Griffin氏が、DoDの公式文書『Digital Engineering Strategy(デジタルエンジニアリング戦略』」の中で、防衛システムの開発、調達、維持における新しい手法の採用により戦力即応性を回復することの重要性を強調しています。具体的には、即応性を回復させ、近代化するための持続的で予測可能な投資が、将来起こりうる紛争による影響を軽減する上で不可欠であると指摘しています。国防総省のデジタルエンジニアリング戦略における1つ目の目標は、「組織での意思決定およびプログラムに関する意思決定に必要な情報を提供できるようなモデルの開発、統合、使用を形式化すること」です。これは、多くの民間業界がモデルベースシステムズエンジニアリング(MBSE)を実現するために採用しているプラクティスと一致しています。

OUSDR&Eは、デジタルエンジニアリングの実装を義務付けたDoD指示書(DoDI)5000.97「Digital Engineering」を発表した。

この公式文書『Digital Engineering Strategy』はビジョンと目標を示しましたが、2023年12月21日に、国防省研究技術担当次官室(OUSDR&E: Office of the Undersecretary of Defense for Research and Engineering)は、実装方針を義務付けたDoDI 5000.97『Digital Engineering』を発行しました。OUSDR&Eは、デジタルエンジニアリングを義務付け、その実装手順を示すことで、防衛業界に高いレベルのイノベーションを導入することを要求しました。防衛業界は非常に広範囲かつ多様であるため、DoDI 5000.97に従ってデジタルエンジニアリングに関連するテクノロジーやプロセスを適切に導入すると、防衛に直接関連しない分野を含め、さまざまな業界にその影響が波及することになります。

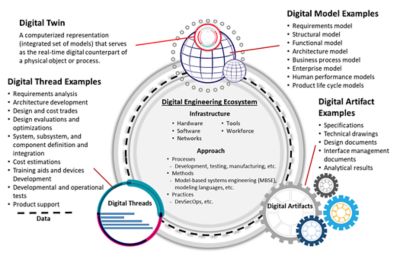

OUSDR&EがDoDI 5000.97サマリーの一環として発表したデジタルエンジニアリングフレームワーク

デジタルエンジニアリングの鍵となるオープンエコシステム

DoDI 5000.97の中心となるのは、開発プロセスの早い段階そして製品ライフサイクル全体でモデルベースのエンジニアリングシミュレーションを導入することです。シミュレーションで実環境を考慮した忠実度の高い仮想モデルを解析することで、より適切な意思決定が可能となり、複雑なシステムの開発を支援します。デジタルエンジニアリングを導入すると、信頼できるデータとデジタルモデルをシミュレーションプロセスおよびデータ管理(SPDM)ソリューションに接続するデジタルスレッドを介して、組織全体の主要な意思決定者が知見を得られるようになります。

デジタルエンジニアリングは、シミュレーションを活用できるだけでなく、マルチフィジックスシミュレーションとワークフローを統合することで変革を可能にするため、このような恩恵を得られます。エンジニアリング解析とシステム要件を双方向で接続することで、目指すべき機能性、コスト、および性能を確実に達成できるようになります。

オープンエコシステムがデジタルエンジニアリング戦略の鍵となるのは、こうした理由からです。OUSDR&E DoDI 5000.97のサマリー文書では、デジタルエンジニアリングエコシステムとは、「システム開発ライフサイクルのあらゆる段階でデジタルアプローチをサポートするために必要なインフラとアーキテクチャ(ハードウェア、ソフトウェア、ネットワーク、ツール、人材)」と定義されています。企業の中には、ワークフローをすでに確立している企業もあります。このワークフローとオープンエコシステムを接続することで、新たなテクノロジーを拡張性と相互運用性に優れた方法で採り入れることができ、長期的に必要なツールを使い続けることができるようになります。変化し続ける環境に対応しながら、継続的に発展し続ける柔軟性を得るには、最新のテクノロジーニーズや市場トレンドにいち早く対応し、規制や指令に準拠できるようなオープンエコシステムが不可欠となります。

DoDI 5000.97の定義

DoDI 5000.97は、いくつかの例外を除き、すべての防衛プログラムにデジタルエンジニアリング(DE)を組み込むことを義務付ける指令です。これは、国防総省の調達ライフサイクル全体にわたってデジタルエンジニアリングを実装するためにシステムモデルとデータモデルを使用する、防衛業界におけるシステム開発と維持への新しいアプローチを表しています。

この方針の変更は、国防総省でのシステム情報の主な伝達手段を、これまでのドキュメントベースのアプローチから、デジタルモデルとそれらが提供するデータを管理するアプローチに移行するための大幅な転換を表しています。また、組織全体でプロジェクトをサポートするためのデータとモデルの信頼できる唯一の情報源を確立するために、デジタルエンジニアリングのエコシステムを構築することも重視されています。

このように、デジタルエンジニアリング機能は、技術的に正確なデジタルシステムや、モデルベースシステム、サブシステム、およびそのコンポーネントの開発、検証、妥当性確認、使用、キュレーション、構成管理、および保守を提供するものと定義されます。これには、開発、セキュリティ、運用(DevSec Ops)のテスト、プロセス、およびソフトウェアが含まれます。これらはすべて、特定の方針、標準、ベストプラクティスに従って、安全なエコシステム内で運用されることが必要です。そのためには、データやモデルの信頼できる唯一の情報源(ASoT: Authoritative Source of Truth)を確立する必要があります。

米空軍(Brigadier General)を退役し、現在はAnsysにて航空宇宙・防衛部門のCTOを務めるSteve Bleymaierと、Ansys Government InitiativesのPresidentであるKevin Floodは、Defense Newsに投稿した記事の中で、次のように述べています。「オープンなエコシステムによるデジタルエンジニアリング環境を構築することで、効率的なレガシーツールやレガシープロセスを開発し直したりする必要性を大幅に削減、あるいは完全に排除できます。また、新しいテクノロジーを最大限に活用しながら、組織が培ってきた専門知識をフル活用できるようにワークフローを適応させることもできます。」

エンジニアリングシミュレーションソフトウェアと、それに接続されるテクノロジーは、複数の業界にわたり、製品ライフサイクル全体でデジタルエンジニアリングを推進する。

移行を成功させるためのツール、トレーニング、サポート

この移行において重要なのは、デジタルエンジニアリングを採用する際に、直感や経験よりも定量解析を優先する考え方です。定量解析はリスクを回避する傾向があり、階層的な性質を持つ組織構造で、役割がより厳密に分離および定義されている従来の環境からは大きく逸脱するものです。

AnsysのSenior Technical Account ManagerであるArmond Sinclairは、次のように述べています。「Ansysでは、システムのライフサイクル全体にわたってトレーサビリティと一貫性をもたらすデジタルスレッドの概念をサポートでき、ユーザーが直感的に操作できるデータ管理およびプロセス統合ツールの開発を優先しています。すべてがモデルベースのエンジニアリング環境とシームレスに統合され、ドキュメント中心からモデル中心のエンジニアリングプラクティスへの迅速な移行が可能になります。」

Ansysの製品コレクションには、デジタルエンジニアリングの導入をサポートするツールが複数含まれています。

- エンタープライズレベルのSPDMソフトウェアであるAnsys Minervaは、重要なシミュレーションデータを信頼できる唯一の情報源として保護します。

- Ansys ModelCenterは、エンジニアがマルチツールワークフローを作成および自動化し、製品設計を最適化して、要件とエンジニアリングを結びつけることで、MBSEを可能にします。

- プロセス統合および設計最適化ソフトウェアであるAnsys optiSLangは、最もロバストな設計構成を効率的かつ自動的に検索するアルゴリズムにより、シミュレーションツールチェーンの自動化を可能にし、意思決定を迅速化します。

- Ansys System Architecture Modelerツールは、複雑なシステムを可視化、設計、および管理する包括的なフレームワークを提供します。これにより、ステークホルダー間で効率的なコミュニケーションを行い、ビジネス目標にあわせて技術ソリューションを調整し、潜在的なリスクを早期に特定して、MBSEを可能にすることで意思決定を強化できます。

- 材料管理ソフトウェアであるAnsys Granta MI Enterpriseは、材料の選定、制御、解析を可能にします。

- シミュレーションベースのデジタルツインプラットフォームであるAnsys Twin Builderを使用すると、エンジニアはシミュレーションベースのデジタルツインを作成して、システムの設計と最適化、さらには予知保全を行えるようになります。

シミュレーションベースのデジタルツインにより、システムの設計と最適化、予知保全が可能になる。

また、クラウド対応の生成AIプラットフォームであるAnsys SimAIとAIの統合、そしてオンプレミスおよびクラウドベースのハイパフォーマンスコンピューティングにより、ツールの拡張性が向上し、さまざまなエンジニアリング専門分野のユーザーや物理的に離れた場所にいるユーザー間の連携が促進されます。こうした拡張性や連携に関するメリットは、デジタルミッションエンジニアリングソリューションを使用したマルチドメイン運用環境にまで及び、エンジニア、オペレーター、アナリストは、エンジニアリング製品のライフサイクルのすべてのフェーズでモデリングとシミュレーションの取り組みを関連付けることができます。さらに、セキュリティに重点を置いた開発のためのツールには、Cybersecurity Maturity Model Certification(CMMC)プログラムの基準を満たすロバストなセキュリティ対策を導入しています。これは特に、防衛分野のデータ保護要件を満たすために、クラウドベースのソリューションで採用されています。

Sinclairは次のように述べています。「Ansysのオープンエコシステムは、その性質上、DoDI 5000.97を迅速かつ確実に実装するために必要なさまざまなソフトウェアツールやプラットフォームを容易に接続することができます。シームレスな統合により、モデリングツール間の相互運用性、システムモデル用の標準化されたデータ交換フォーマットの開発、モデリング、検証、可視化のための統合されたインターフェースの開発が保証されます。」

デジタルエンジニアリングを実現するツールとプロセス

- 信頼できる情報源(ASOT)。米国宇宙軍では、古い情報、矛盾する情報、不正確な情報を使用するリスクを軽減するために、すべての使用者が参照すべき唯一かつ決定的な情報源として定義しています。

- 人工知能。自動化された最適化と優れた拡張性により、デジタルエンジニアリングの多くの目標をサポートするために活用できます。

- デジタルスレッド。国防省研究技術担当次官室(OUSDR&E)では、信頼できるデータとデジタルモデルを接続し、システムのライフサイクルを通じて意思決定者に実用的な情報を提供するものと定義しています。

- デジタルツイン。一定の頻度と精度で現実と同期しながら相互作用する、実際のエンティティやプロセスの仮想的表現です。

- モデルベースシステムズエンジニアリング。ドキュメント中心のシステムズエンジニアリングとは対照的に、情報、フィードバック、要件を交換する主要な手段として、デジタルシステムの作成と利用、さらにはドメインモデルのエンジニアリングに焦点を当てた方法論です。

- プロセス統合および設計最適化(PIDO)ソフトウェア。複数のソフトウェアツールを含む複数のステップまたはサブプロセスを便利なパッケージにつなげた「ツールチェーン」として形成することで、コストを最小限に抑えながら最大限の成果をあげます。

- シミュレーションプロセスおよびデータ管理(SPDM)。ワークフローの効率化、連携、データ管理が可能になります。また、シミュレーションを他の製品ライフサイクルプロセスと接続することで、デジタルスレッドを作成できます。

Advantageブログ

Ansys Advantageブログでは、専門家が投稿した記事を公開しています。Ansysのシミュレーションが未来のテクノロジーにつながるイノベーションをどのように推進しているかについて最新の情報をご覧ください。