Electric Vehicle Battery Systems

Widespread adoption of electric vehicles (EVs) depends on battery technology that can reduce range anxiety, lower costs, and increase safety. It requires new approaches to collaboration, prototyping and testing, and production to satisfy increasingly aggressive timelines and tighter budgets.

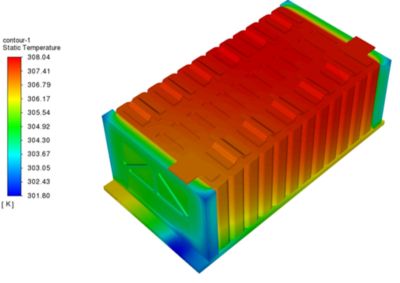

Simulation supports the multidisciplinary, model-based engineering approach needed to balance safety, energy density and battery life. In this way, Ansys solutions are transforming automotive engineering teams, encouraging up-front, virtual product development, inspiring collaboration, and refining processes that drive automotive innovation.

Find out why Ansys is the right partner for EV battery design and manufacturing:

- Battery Cell-to-Pack Design: Electrode performance, thermal management, mechanical abuse and durability

- Battery Management System-Vehicle Integration: BMS architecture and development, design safety analysis, predictive battery aging

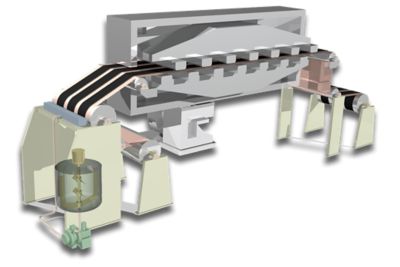

- Battery Manufacturing Process and Production: Calendaring, film casting, mixing tank simulation, coating slot die…