-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

Ansysブログ

October 13, 2023

デジタルの波に乗る: SPDMでデータオーバーフローを解消

自動車や航空宇宙から、コンシューマー向けエレクトロニクス製品、ヘルスケアまで、ほぼすべての業界がデジタルトランスフォーメーションの影響を受ける中、企業はこれまで以上に多様なツールやテクノロジーを導入しています。新しいワークフローを採用することで得られるメリットはあるものの、部署ごとに異なるテクノロジーを採用したり、ソリューションが接続されていない状況では、生産性が低下して、組織のサイロ化が生じることもあります。加えて、ツールセットごとに独自のデータセットが保持されるため、問題はさらに複雑になります。結果として情報過多になるだけでなく、分断されたデータやワークフローが増え、他のチームや過去のプロジェクトからデータを探し出す必要性が生じます。

では、どのようにすればうまくデジタル化の波に乗り、データのオーバーフローを解消できるでしょうか。シミュレーションプロセスおよびデータ管理(SPDM)ソフトウェアは、実装が最も簡単なソリューションの1つです。SPDMを使用することで、さまざまな部署や異なるエンジニアリング分野から構成された組織全体のシミュレーション、データ、ワークフロー、リソースを、一元化されたデータベースから管理できるようになります。つまり、Ansys MinervaのようなSPDMソリューションを導入することで、企業は製品ライフサイクルの全ての段階にわたるデジタルスレッドを作成し、生産性を向上させ、より良い設計を作成し、さらにはコラボレーションを向上させることができます。

Ansys MinervaなどのSPDMソフトウェアを使用することで、組織全体のシミュレーション、データ、ワークフロー、リソースを、一元化されたデータベースから管理できるようになります。

SPDMで過剰なデータに対応

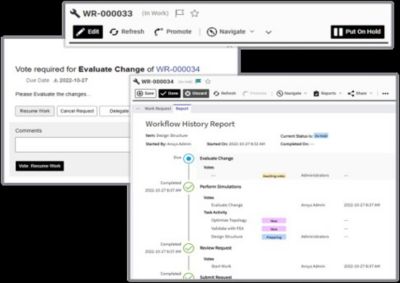

SPDMは、今日のワークフローで最も難しい課題や問題点を解決します。前述したように、デジタル化社会の共通の課題は、企業全体で多数のツールやテクノロジーが導入されてはいるものの、ソリューション同士が必ずしも接続されていないことです。さらに、多くの企業は多分野にわたるチームで構成されているため、ワークフローはさらに複雑になります。SPDMを導入すると、数十から数百のツールを1つの共有データベースに統合して、複数のユーザーが共有ファイルを表示して使用し、作業リクエストを定義できるようになります。

Minervaは、業界をリードするSPDMソフトウェアとして、オンプレミスとクラウドの両方の展開環境での管理および意思決定をサポートしながら、機能を提供します。これにより、作業場所、所属部署、その他の作業空間の制限に関係なく、チームメンバーがさらに容易につながることが可能になります。

管理者やチームメンバーは、Minervaを使用して進行中の作業のステータスや指標などを取得できるため、担当者の不在や組織内での変更による生産の遅れを防ぐことができます。

さらに、Minervaでは一般的なローカルアプリケーションからデータフローを構成、起動、管理できるため、各チームメンバーが使い慣れたプログラムやワークフローを使用しながら、他のチームメンバーと効率的にコラボレーションすることができます。このように、SPDMによってシミュレーションの操作性が向上し、誰もが活用できるようになります。

同様に、管理者とチームメンバーは、Minervaの構成可能なロールベースのダッシュボードを使用して、オフィスにいるか、あるいはシミュレーションのエキスパートかどうかに関係なく、進行中の作業のステータス、主要な指標、担当業務などを取得できます。その結果、担当者の不在や、体制の変更など、ワークフローに支障をきたす組織内での変更による生産の遅れを防ぐことができます。

SPDMを使用したデジタルスレッドの作成

デジタルスレッドとは何か、そして組織にとってどのように役立つのでしょうか。デジタルスレッドとは簡単に言えば、デジタルソリューションの接続です。しかし、それ以上に人、ツール、プロジェクトの間で接続性が確立される点が重要です。このシームレスなデジタルスレッドは、SPDMソリューションが本来備えているコンポーネントとしてシミュレーションワークフローに適用できます。言い換えれば、シミュレーションワークフローを単に整理するためにSPDMソリューションを導入したとしても、SPDMによって、プロセスのワークフロー内にツールやアプリケーションのデジタルスレッドが作成されます。これは、業界に関係なく、あらゆる企業にとって有益です。

シミュレーションソリューションのデジタルスレッドは、製品ライフサイクル全体を通してトレーサビリティを向上させるのに役立ちます。つまり、初期段階の概念から後期段階の設計や開発まで、製品とそのデジタルアセットを追跡できるようになります。たとえば、設計者であれば、部署が異なる機械エンジニアなどのエキスパートとモデルを簡単に共有できます。一方で、デジタルスレッドを導入する目的は、製品設計の改善や開発の迅速化だけではありません。デジタルスレッドを導入することで、設計や開発に対する考え方が洗練され、より開放的な職場環境を促します。たとえば、Minervaが備える自動データ抽出機能によってトレーサビリティが保証され、組込みのメッセージング機能によってコラボレーションが促進されます。

Minervaはベンダーに依存しないアーキテクチャを採用しているため、既存のワークフローに簡単かつシームレスに統合できます。また、ワンストップのシミュレーションショップとして機能することで、広く使用されているCADツール、CAEツール、製品ライフサイクル管理(PLM)システムとのネイティブな相互運用性が提供されます。Minervaは、さらに材料管理ソフトウェアのAnsys Granta MI Enterprise、プロセス統合および設計最適化ソフトウェアのAnsys optiSLang、モデルベースシステムズエンジニアリング(MBSE)ソフトウェアのAnsys ModelCenterなど、他のAnsys Connect製品とも簡単に統合できます。

SPDMは、運用効率、生産性、デジタルトランスフォーメーションをサポートします。

SPDMで物事をシンプルに

テクノロジーの急速な進歩により、世界中の企業はデジタルトランスフォーメーションを受け入れ、最新のワークフローに適応する必要に迫られています。そして、多くの企業がシミュレーションの知見を広く活用して、より多くのデータを生成するようになりました。効果的なSPDMソリューションは、運用効率を最適化し、生産性を向上させ、デジタルトランスフォーメーションをより迅速かつスムーズに導入する手助けとなります。

Minervaの詳細やSPDMソリューションがもたらすメリットについては、Ansys Minervaウェビナーシリーズに登録して、オンデマンドでご覧ください。