-

-

学生向け無料ソフトウェアにアクセス

Ansysは次世代の技術者を支援します

学生は、世界クラスのシミュレーションソフトウェアに無料でアクセスできます。

-

今すぐAnsysに接続!

未来をデザインする

Ansysに接続して、シミュレーションが次のブレークスルーにどのように貢献できるかを確認してください。

国および地域

無料トライアル

製品およびサービス

リソースとトレーニング

当社について

Back

製品およびサービス

In today’s aerospace and defense landscape, the rapid proliferation of new and emerging technologies, manufacturing methods, materials, policies, and interconnected end-to-end solutions is driving change. As a result, the A&D industry is becoming increasingly complex.

Rising system complexity isn’t the only challenge that A&D leaders face, either. There’s also a growing demand to innovate and develop systems faster due to economic and geopolitical pressures, especially in the air and space domains. Due to these demands, the pressure to continuously iterate and deploy new products and technologies is higher than ever.

These goals must be met while simultaneously ensuring safety and minimizing timelines and costs, which is a difficult yet essential balancing act to achieve.

As Greg Kaminsky, industry marketing lead at PTC, puts it, A&D organizations must adapt to “a world of growing complexity, tighter timelines, and rising demand.” Addressing these challenges requires finding critical solutions for accelerating product development. One such solution is digital engineering.

To learn more, Kaminsky recently sat down with Danny Poisson, TVP, CTO FA&D, PTC; Jeremy Morse, director of global FA&D CAD sales, PTC; and Steven Bleymaier, brigadier general (retired), U.S. Air Force, and CTO for A&D, Ansys, part of Synopsys. Here are a few highlights from their conversation.

Left to right: panel speakers Jeremy Morse, Steven Bleymaier, and Danny Poisson

Managing Growing A&D Challenges With Simulation and Digital Engineering

Despite experiencing rapid changes, A&D engineers find themselves turning to a technology that has reliably advanced with technological innovations throughout the years: simulation.

As Poisson notes, simulation has been used for a long time, such as for training pilots in World War II. Since then, its functionality and fidelity have increased, with various catalysts, including the space race, rising computing capacity, and computer-aided everything (CAx), driving its evolution and growth.

Today, simulation is a key part of digital engineering, which is a critical approach for the future of A&D. Digital engineering, along with the other enterprise systems required to develop today’s increasingly complex products, can connect system architecture, requirements, simulations, computer-aided designs (CAD), artificial intelligence (AI), and digital twins with a digital thread.

As an example of the advantages of digital engineering, consider the James Webb Space Telescope. Digital engineering was critical throughout its development. In fact, “they had no choice (but to use digital engineering),” says Bleymaier. “You only get one shot, and you can’t physically test that before you send it out. … All of that had to be done with simulation and digital engineering prior to shooting that thing into space, and the results speak for themselves.”

Digital engineering isn’t just a beneficial approach, either — it’s becoming a necessity. National directives, such as DoDI 5000.97, are mandating the use of digital engineering and accelerating the sector’s digital transformation.

But how can you best employ digital engineering at your organization? To aid in this process, PTC and Ansys collaborated to create a blueprint of a connected digital engineering ecosystem that helps A&D leaders enhance their understanding of complex interdependencies and systems throughout the product development process.

A Blueprint for Digital Engineering

The digital engineering blueprint provides guidance on how solutions from PTC and Ansys unify software and hardware requirements, modeling, simulation, and product life cycle management (PLM) into a single connected digital ecosystem that reduces development time by letting multidisciplinary engineering teams collaborate and work concurrently.

“Think of us as a football team where Ansys fills half of the positions on the football team and PTC fills the other half of the positions of the football team,” says Bleymaier. “Together, as a team, we’re able to provide game-winning strategies for our customers.”

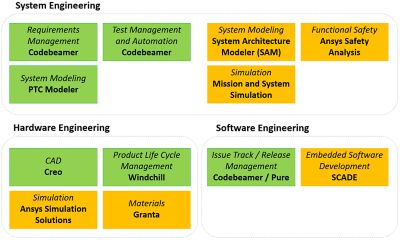

This digital engineering blueprint combines key capabilities of both companies, as seen in the graphic below.

The PTC (green) and Ansys (gold) contributions to the digital engineering blueprint

Through this collaboration, “we complete a large portion of a digital ecosystem that is needed for our customers to do product development,” says Poisson. The blueprint supplies a reference architecture that organizations can use to select best-in-class connections and products for each use case. This helps customers “reduce complexity, be able to build this right, and have that continuity that is needed for that product acceleration,” says Poisson.

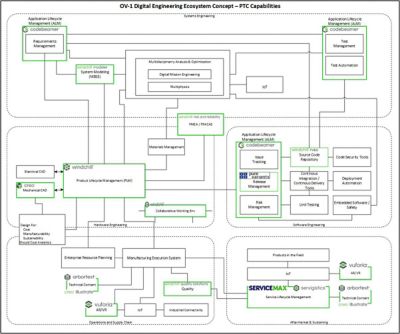

The reference architecture for the digital engineering blueprint

Using this digital engineering architecture, engineers can:

- Break down their products into different parts to ensure that all mission requirements are met

- Efficiently explore concepts, systems characteristics, and design alternatives

- Leverage advanced simulation to validate designs earlier and reduce risk across critical systems

- Analyze more detailed designs in CAD environments

- Use project life cycle management (PLM) software to aid in collaboration and management

- Make informed decisions based on overall system performance

In short, this collaborative digital engineering ecosystem enables a traceable digital thread that extends an authoritative source of truth throughout the product life cycle, from requirements through validation. This critical functionality yields a range of key benefits.

The Advantages of a Connected Digital Engineering Ecosystem

A few of the key benefits that customers gain from this partnership include:

Saving Time and Costs

Engineering departments throughout the A&D industry are operating with limited bandwidth to achieve their goals and meet rapidly accelerating timelines. Engineers can address this challenge by using digital engineering to:

- Enable rapid iteration and early validation to accelerate innovation

- Minimize cost overruns and spending on prototyping, rework, and late-stage changes

- Leverage advanced simulation to validate designs earlier and reduce risk across critical systems

- Reduce complexity across hardware and software systems to manufacture at speed and scale while meeting mission requirements

- Minimize rework and physical testing with model-based test studies

- Achieve faster time to certification by cutting months from test-and-redesign loops

An example of digital engineering in action while using both PTC and Ansys solutions

Reducing Risk

Is the key to success to fail quickly? This adage is “precisely what this technology allows us to do,” says Morse. “We have to fail quickly in a digital sense. And that’s precisely what this partnership enables: an agile approach at failing quickly to succeed.”

Essentially, digital engineering helps innovators rapidly test different designs and receive immediate feedback on how these changes affect the design, from requirements to sustainment, thereby increasing first-pass success.

With this collaboration, engineers can safely test ideas that they may have previously thought were too risky or extreme, says Poisson. In doing so, they are clearing the way toward faster innovation.

Reducing risk also ties back to saving costs and time. For example, Morse recalls a major defense organization that had a 16-week delay between when CAD work was handed off to a simulation team and when it received pass/fail results. Digital engineering enables organizations like this to speed up this process. “What our partnership does is very precisely and surgically attack that problem by tying those two solutions together in a common interface where engineers, for the first time, have full access to these tools in one version iteration managed environment,” says Morse.

“If the engineer can fail quickly and can get 80% further in a design in 20% of the time and reduce some of these 16-week back-and-forth cycles, that’s where the real rubber meets the road, and that’s where you can put hard dollars to this,” says Morse. Additionally, using digital engineering early in the product life cycle “will help minimize or even eliminate the need for physical prototypes,” says Bleymaier. “All of that results in risk reduction, and when you reduce risk, you increase speed and you reduce costs. Using simulation as early as possible impacts the future cost of operations and sustainment because those costs are ‘baked in’ very early during the concept development and design phase.”

Enhancing Collaboration

A key benefit of this partnership is the open architecture nature of the PTC and Ansys environments. “We don’t come into a customer’s ecosystem and replace what they have — we add value to it,” says Bleymaier. This open architecture enables collaboration and interoperability across software systems, platforms, services, and nations.

Such collaboration is enhanced due to the use of a single digital thread that connects requirements, architecture, and verification throughout the design, development, and validation processes. Achieving this full life cycle integration eliminates silos and ensures seamless traceability, detailed version iteration control, compliance, and collaboration across the product design, development, deployment, and sustainment stages.

Key Points and Takeaways

Looking ahead, it’s important to remember that digital engineering is a real solution, not just theoretical. “The commercial technology exists today,” says Bleymaier. “It exists right now to achieve your organization’s implementation of digital engineering and to achieve your objectives.” By using digital engineering, organizations can reinvest significant amounts of time into improving their own products and technologies.

This blueprint will enable you to “go to market as an organization with a strong partnership behind you supporting you,” says Morse. “If you want to go fast and far, go together.”

Left to right: Greg Kaminsky, industry marketing lead at PTC; Poisson; Morse; and Bleymaier during the panel “Accelerating Innovation: Rapid Fielding of Aerospace and Defense Solutions”

Throughout the A&D industry, “digital engineering is becoming a critical enabler for speed, agility, and mission success,” says Kaminsky. However, while its importance is known, the process of actually implementing digital engineering may seem daunting. So, “if you don’t know exactly how to start or where to start, please contact us,” encourages Poisson. “We certainly can help customers get on the journey if they’re simply not sure exactly where to get started.”

Learn more about the PTC and Ansys collaboration and download The IDC InfoBrief “Transform Product Innovation with Multiphysics Simulation for Digital Engineering” for a comprehensive look at how manufacturers can address the growing complexity of modern products.

Just for you. We have some additional resources you may enjoy.

“Digital engineering is becoming a critical enabler for speed, agility, and mission success.”

— Greg Kaminsky, industry marketing lead, PTC

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.